Injection-molding workpiece-taking manipulator brace for sedan bumper

An injection molding and bumper technology, applied in the field of car bumper injection molding pick-up manipulator support, can solve the problem of irregular shape of bumper, achieve stable and reliable suction and payment, save the time of injection molding machine, and accurately control the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

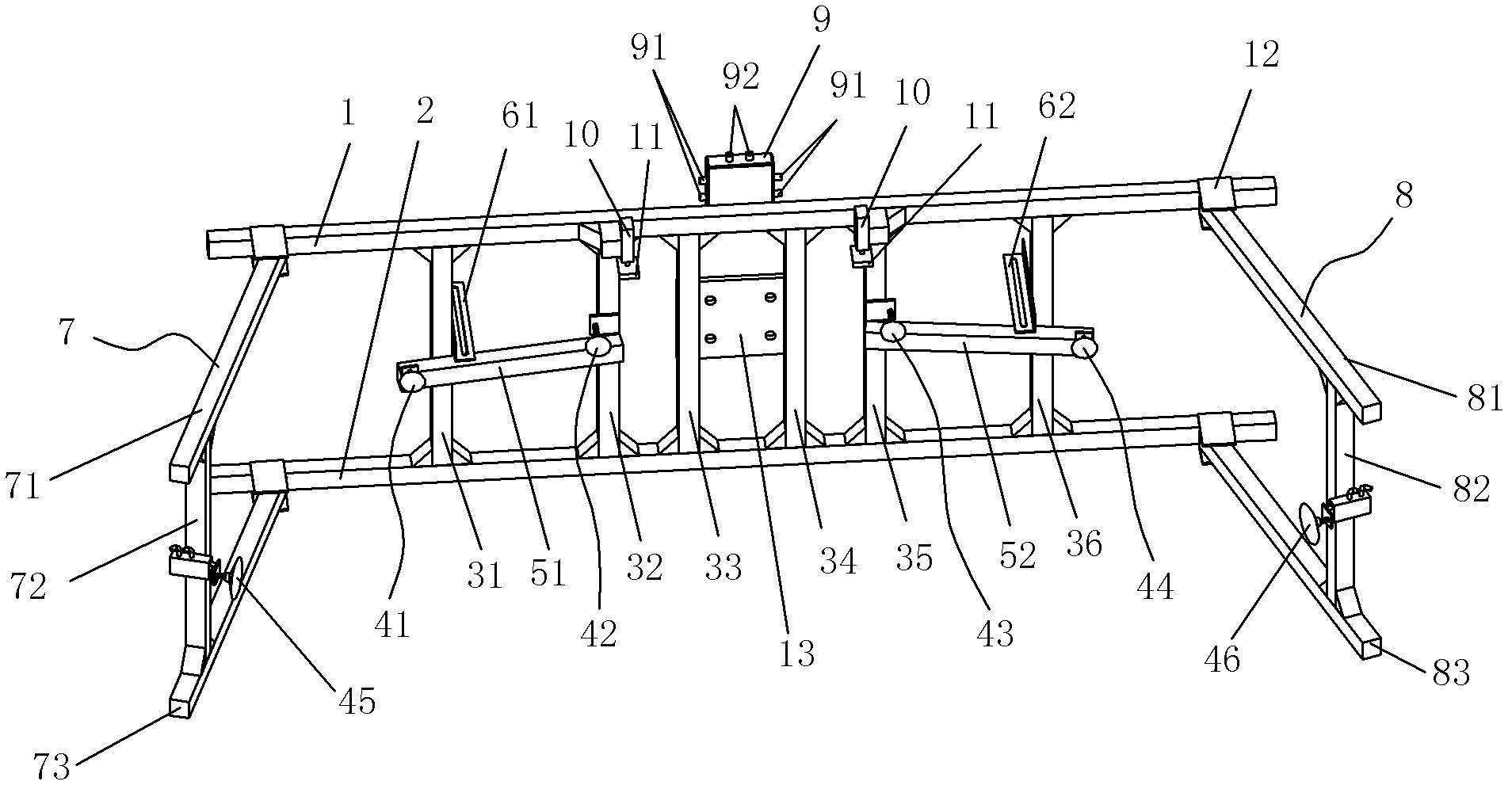

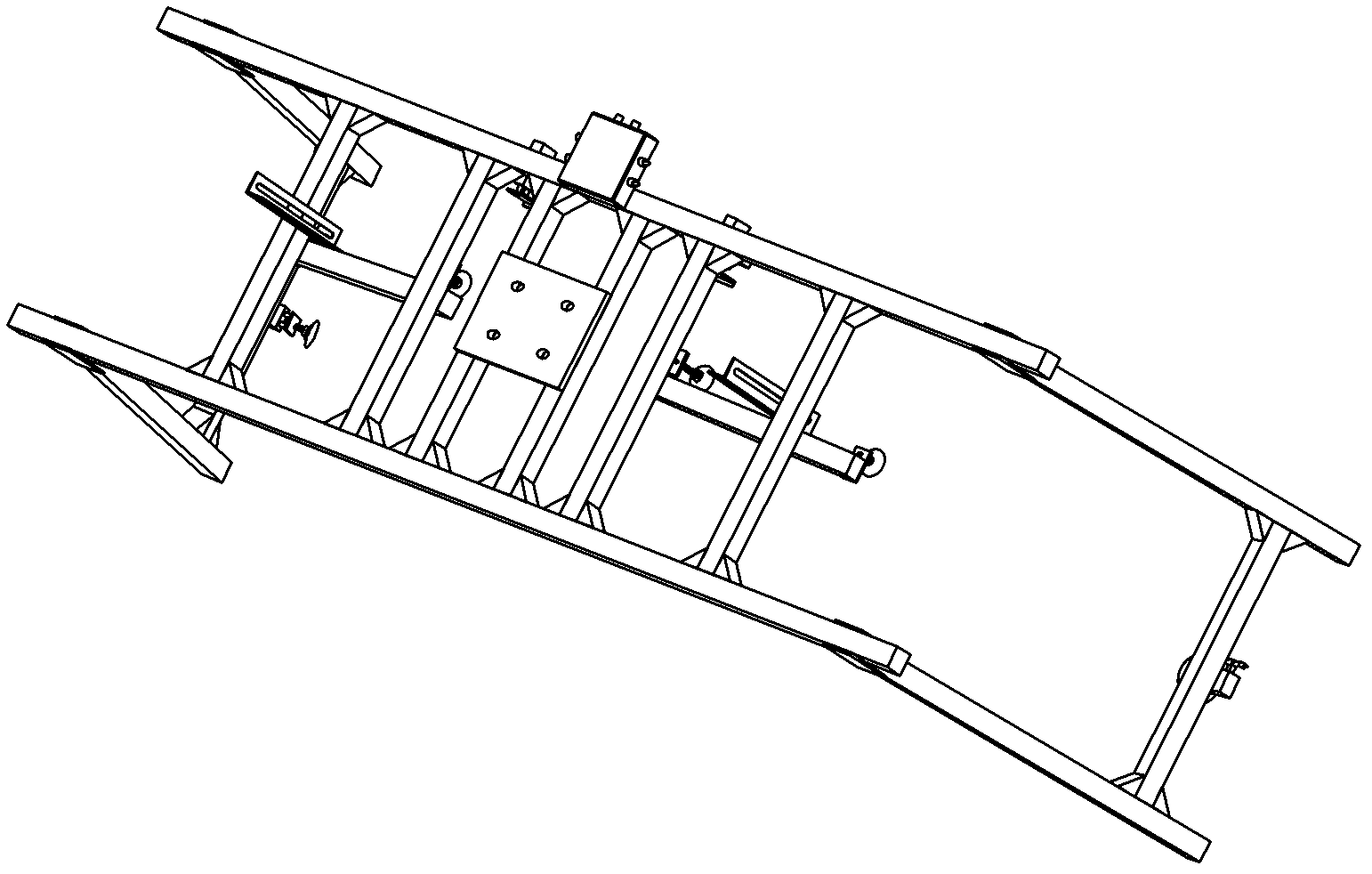

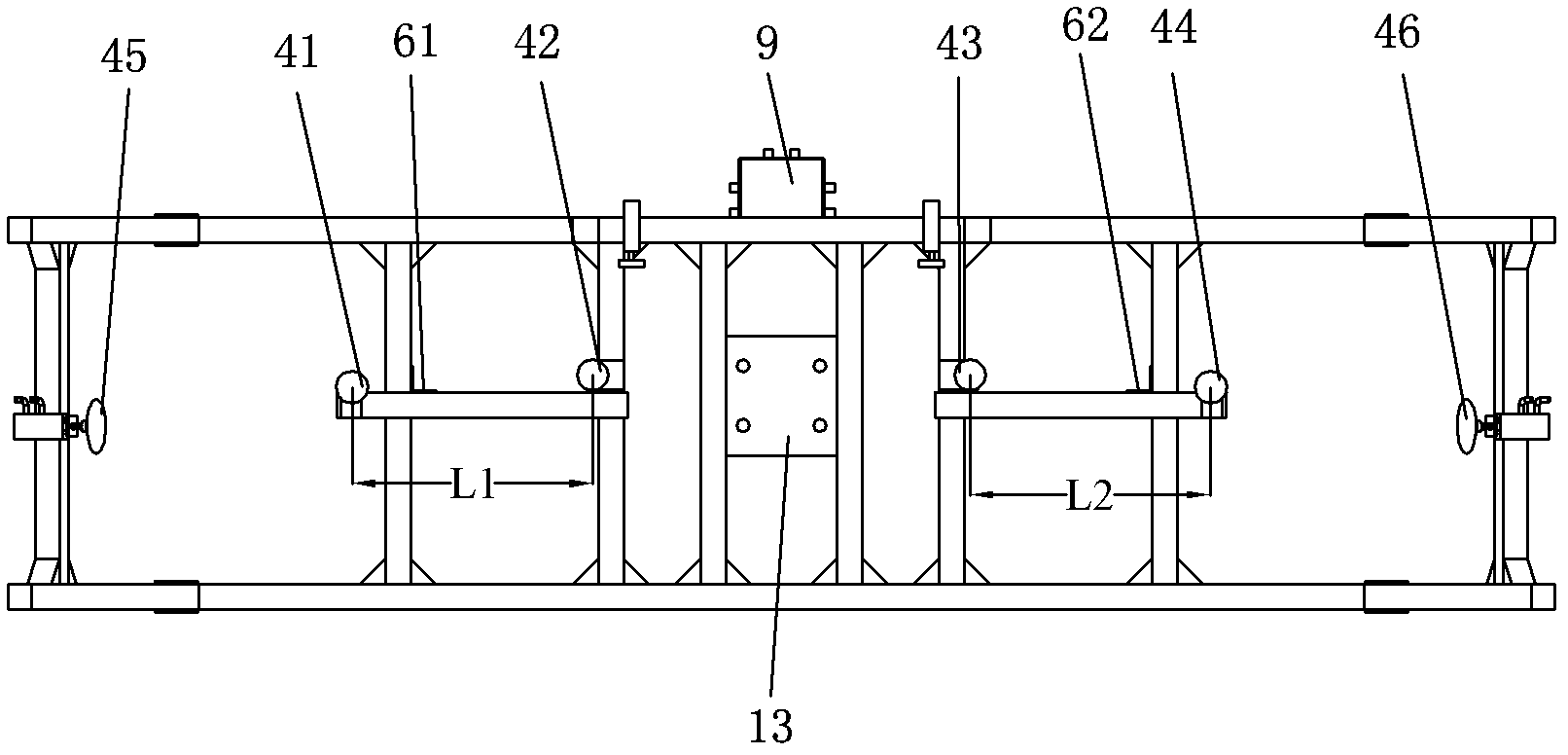

[0024] Embodiment 1: A kind of car bumper injection molding pick-up manipulator support (see Figure 1 to Figure 5 ), the brace includes a frame and 6 suction cups, the 6 suction cups are middle suction cup Ⅰ41, middle suction cup Ⅱ42, middle suction cup Ⅲ43, middle suction cup Ⅳ44, left suction cup 45 and right suction cup 46. 401 and the vacuum suction cup 402 connected with the cylinder are formed, and the cylinder is used to drive the vacuum suction cup;

[0025] The frame includes side beams I1 and side beams II2 arranged in parallel, and there are longitudinal beams I31, longitudinal beams II32, longitudinal beams III33, longitudinal beams IV34 and longitudinal beams connected in sequence from left to right between side beams I and side beams II. V35 and longitudinal beam VI36, the longitudinal beam III and longitudinal beam IV are located in the middle of side beam I and side beam II, and the longitudinal beam III and longitudinal beam IV are connected with manipulator c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| suction force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com