Curtain wall board of suspension type curtain wall

A curtain wall panel and hanging technology, applied in the field of building curtain wall system, can solve the problems of self-tapping screw connection failure, large number of curtain wall panels dismantled, and self-tapping screw force, etc., so as to improve the connection reliability and stability, Realize the effect of multi-line cross operation and connection force improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

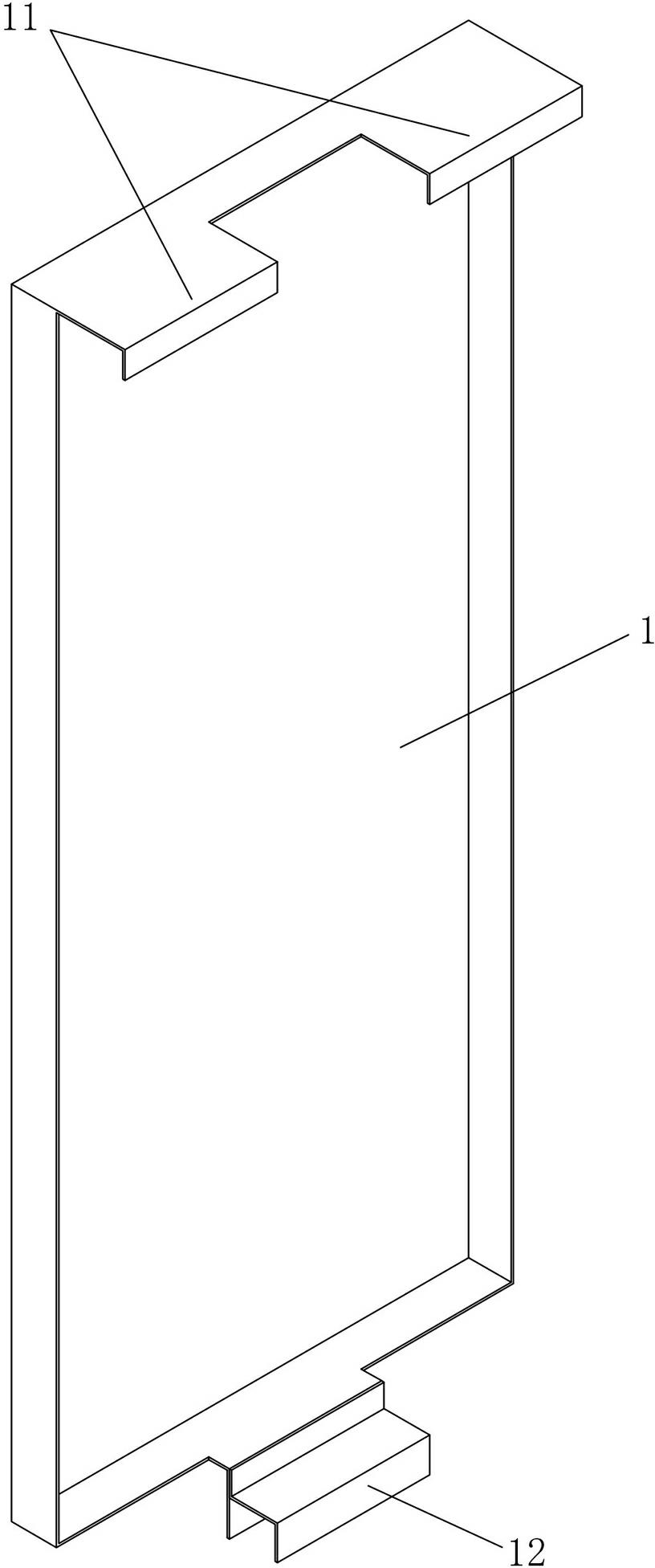

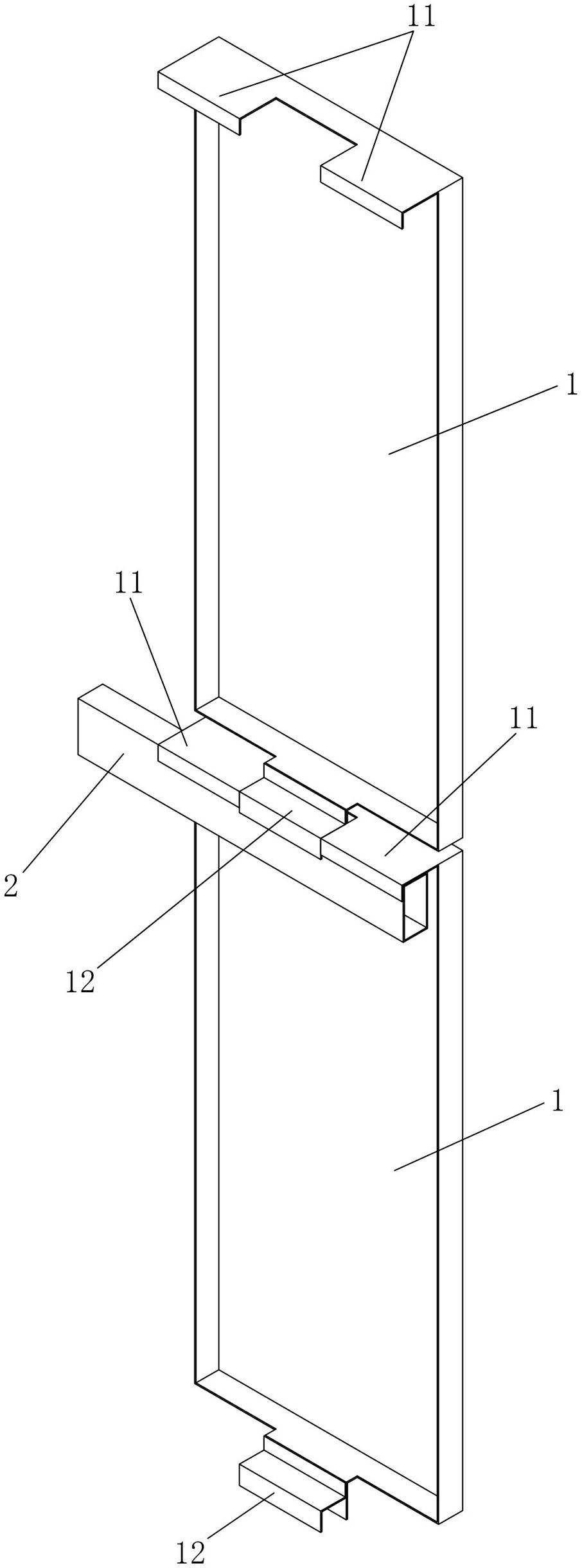

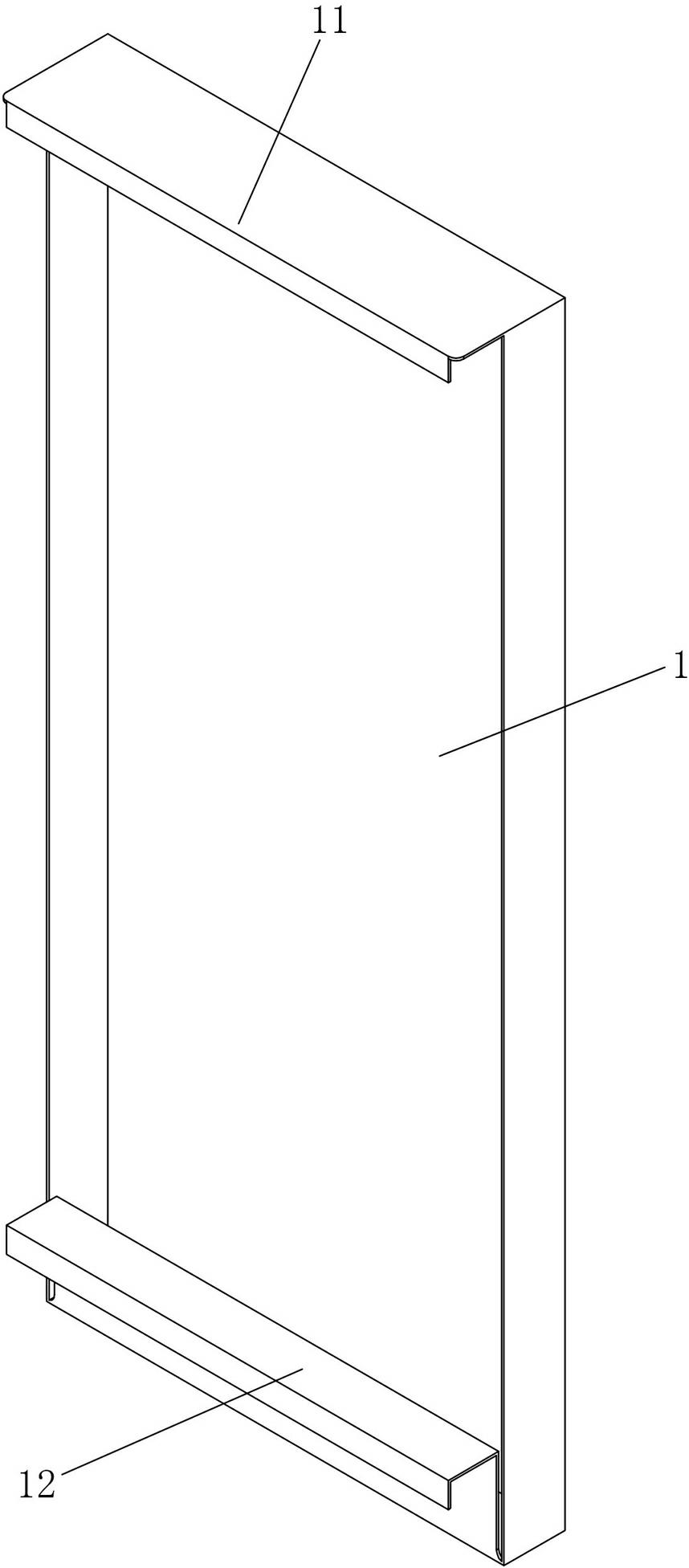

[0023] figure 1 and figure 2 Shown is the curtain wall panel embodiment of the first suspended curtain wall of the present invention, the curtain wall panel includes a curtain wall panel body 1, and the upper part of the curtain wall panel body 1 is provided with an upper hook part 11 that can be hung on the transverse keel 2 of the curtain wall The lower part of the curtain wall panel body 1 is provided with a lower hook portion 12 that can be hung on the horizontal keel 2 of the curtain wall, and the entire weight of the curtain wall panel body 1 can be transferred to the horizontal keel 2 through the upper hook portion 11 and the lower hook portion 12. The force of the connection of the curtain wall panel body 1 is greatly improved, and the reliability and stability of the connection between the curtain wall panel body 1 and the curtain wall keel can be improved, and it is no longer necessary to fix the curtain wall panel and the keel by installing fasteners, and the curta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com