Suspension type curtain wall

A suspension and curtain wall technology, applied in the field of building curtain wall systems, can solve the problems of self-tapping screw connection failure, inconvenient replacement, and low installation efficiency, so as to improve connection reliability and stability, improve connection stress, The effect of convenient alignment and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

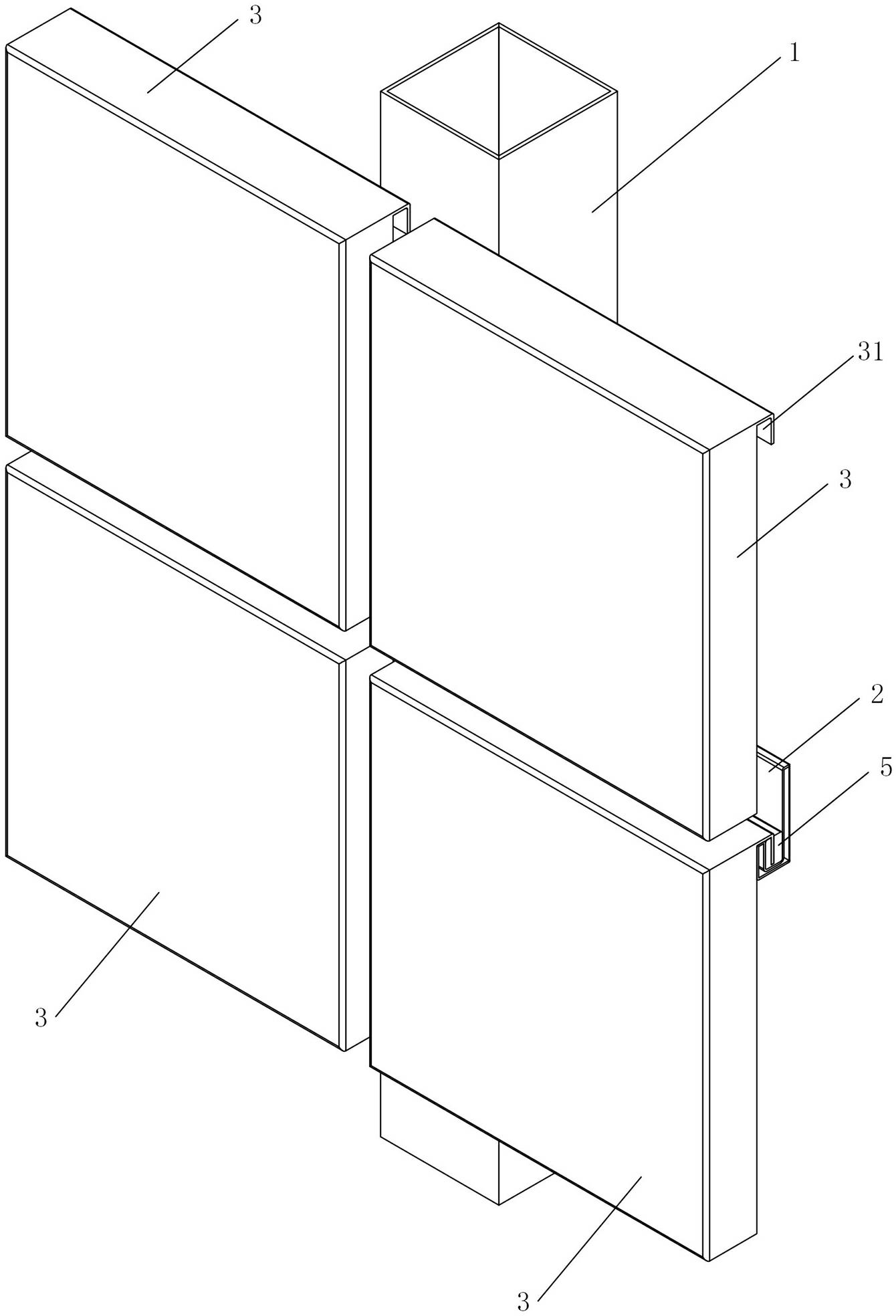

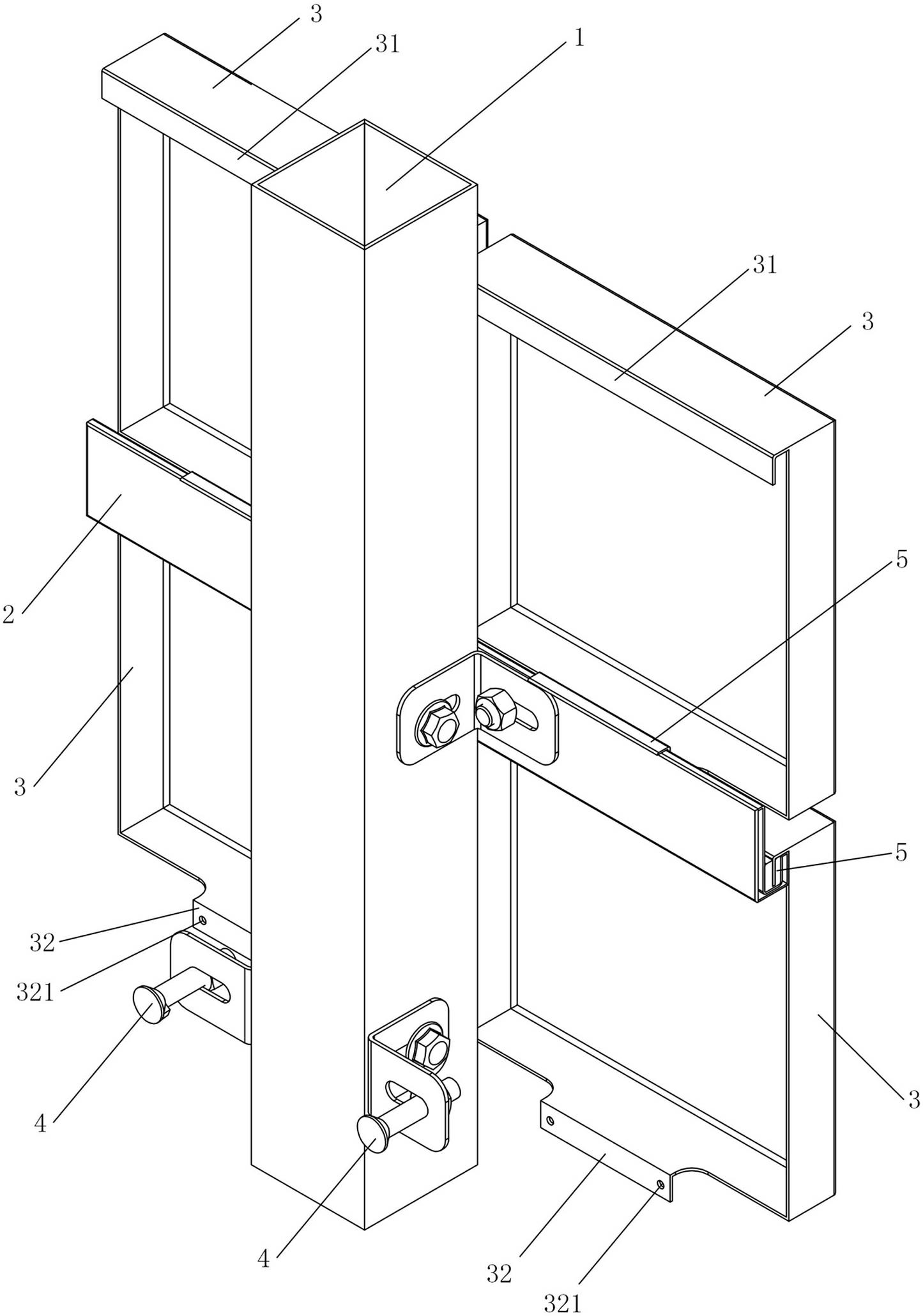

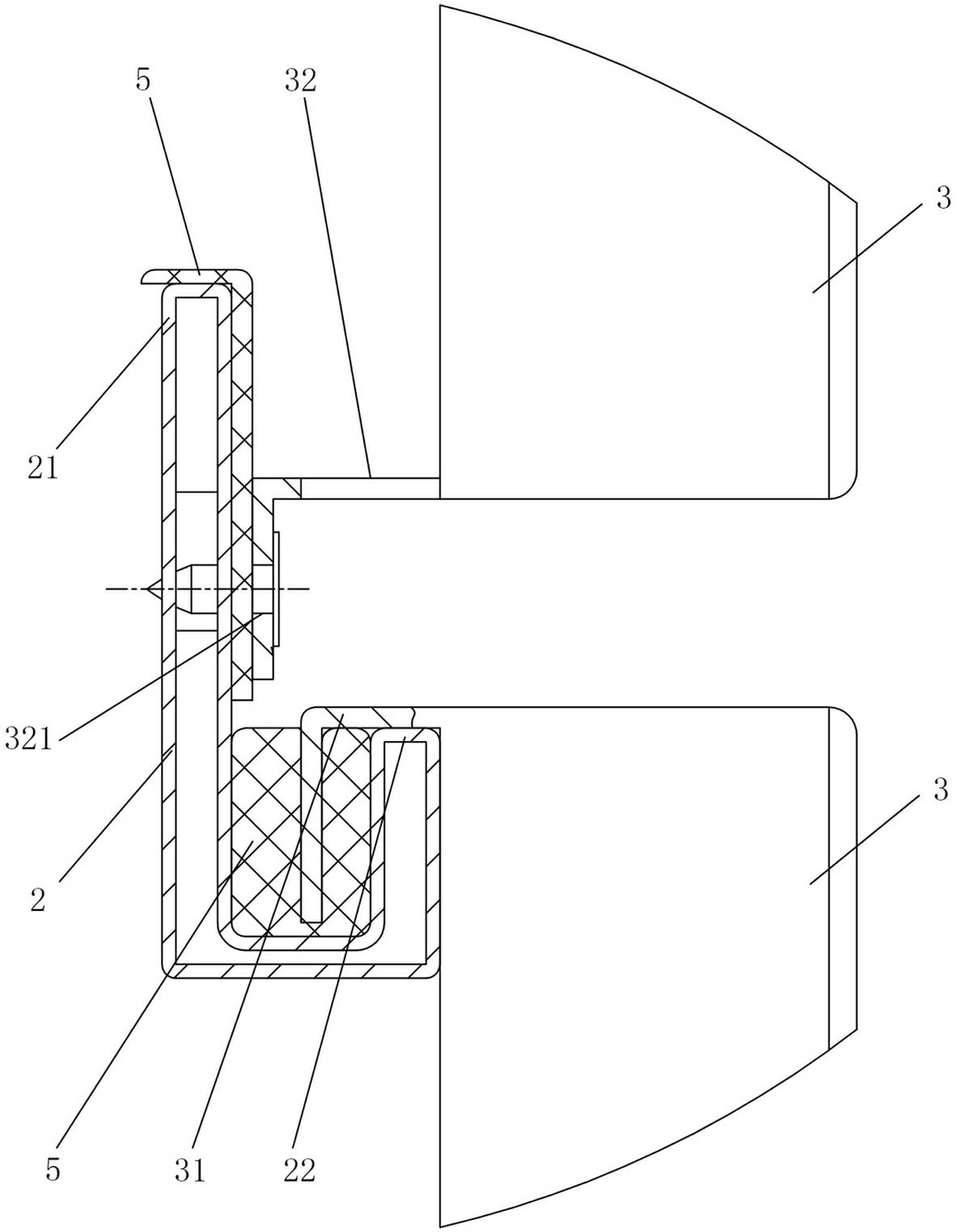

[0020] Figure 1 to Figure 3 It shows an embodiment of a suspended curtain wall of the present invention, the curtain wall includes a vertical keel 1, a horizontal keel 2, several curtain wall panels 3 and an in-wall fastener 4 arranged on the building wall, and the vertical keel 1 passes through the wall The fastener 4 is fixed on the building wall, the horizontal keel 2 is fixed on the outside of the vertical keel 1, and the curtain wall panel 3 is hung on the horizontal keel 2. It is no longer necessary to cut the horizontal keel 2 into multiple sections and install it on the vertical keel 1 during installation. Instead, directly fix the entire horizontal keel 2 and vertical keel 1, which is convenient and quick to install. During installation, the levelness of the horizontal keel 2 can be calibrated and the curtain wall panel 3 can be installed on the horizontal keel 2 as a horizontal reference, and It is no longer necessary to horizontally calibrate the curtain wall panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com