Measuring system for electrical runout amount of revolving body

A measurement system and runout technology, which is applied in the field of electric runout measurement system of rotating bodies, can solve the problems of low efficiency and low precision of manual measurement of runout, and achieve the effect of high flexibility and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

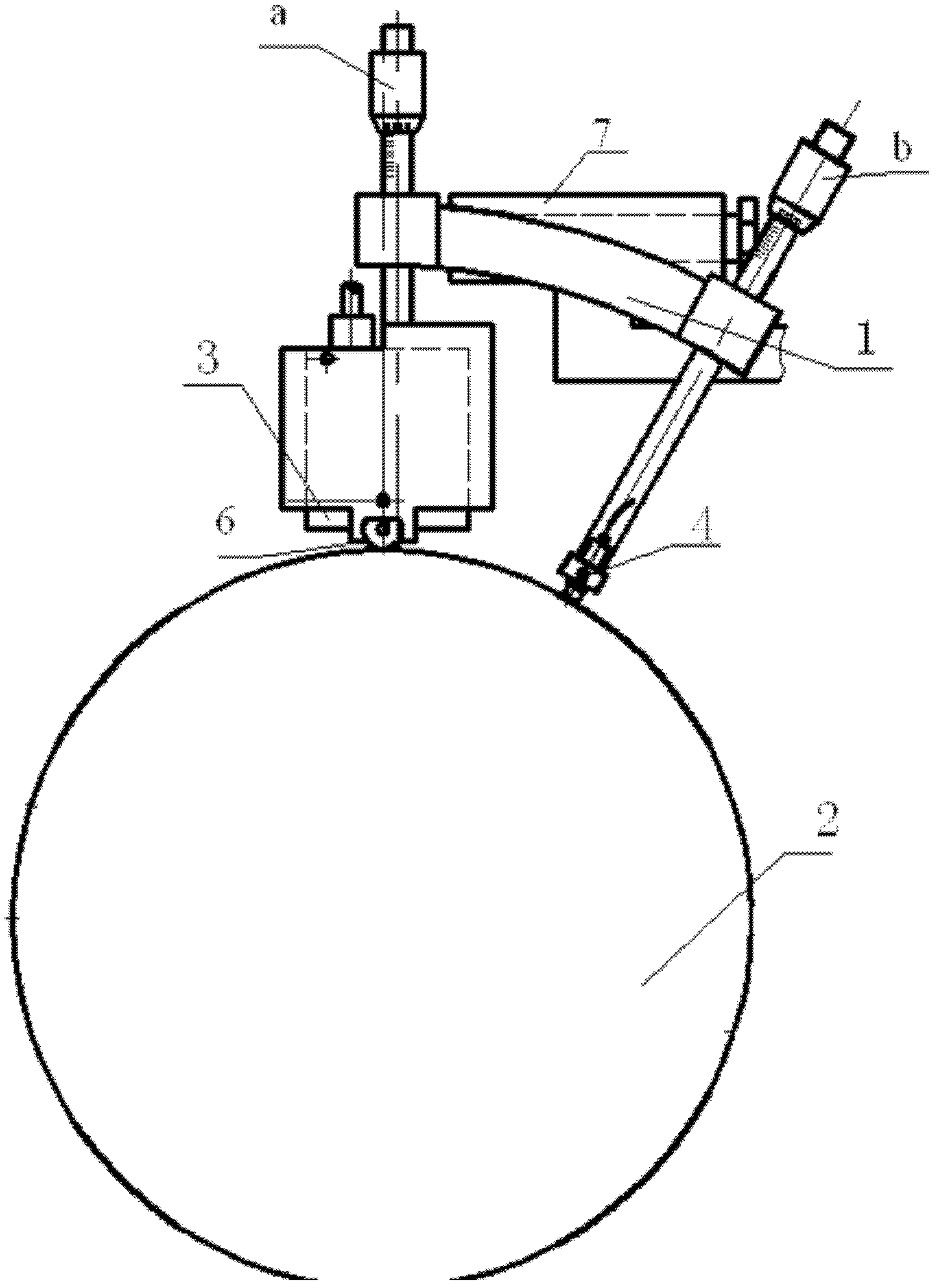

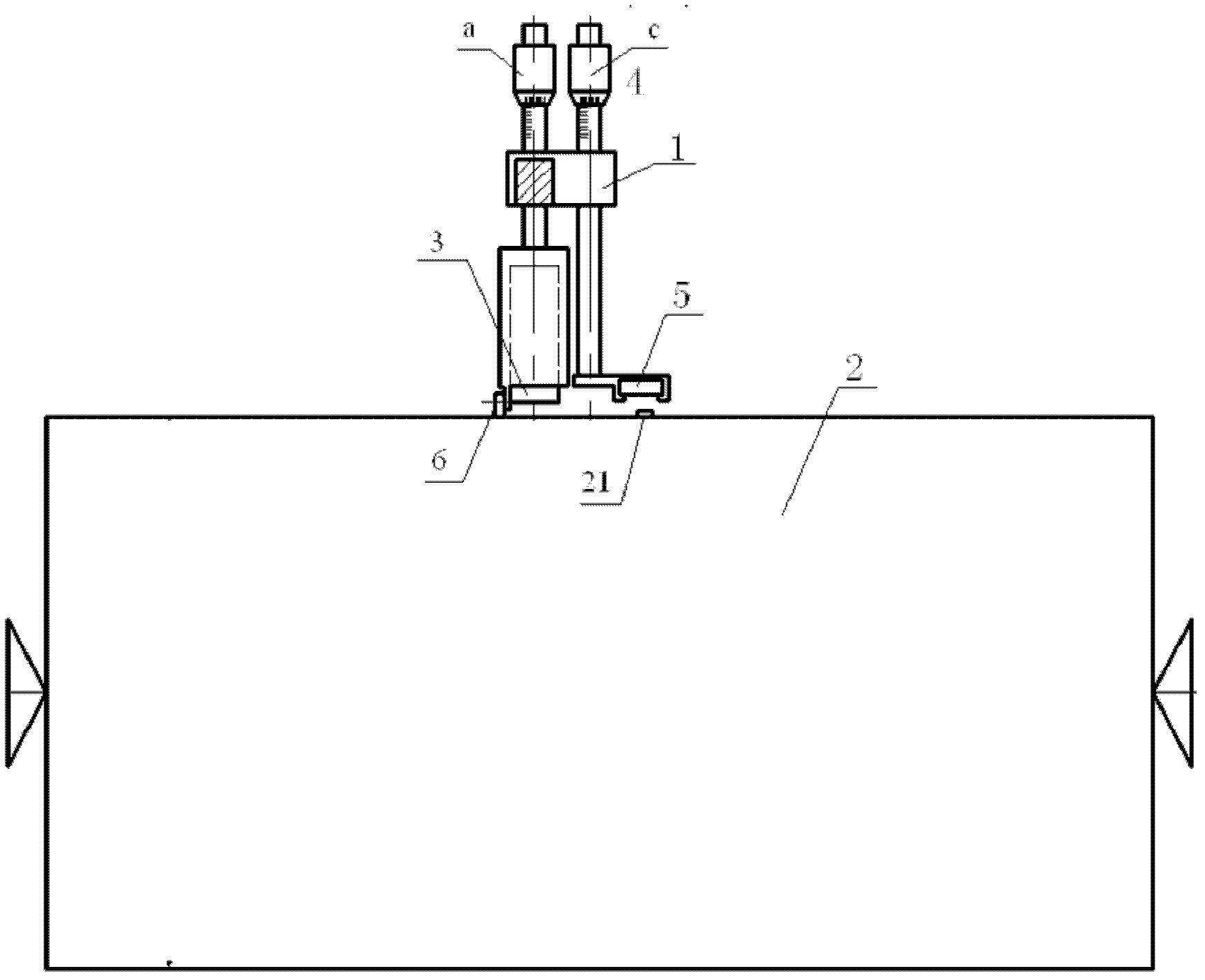

[0026] With reference to accompanying drawing, further illustrate the present invention:

[0027] The system for measuring the electrical runout of a rotating body includes a measuring bracket 1, on which a laser displacement sensor 3 aligned with the measured rotating body 2 to measure the relative movement distance of the surface of the tested rotating body 2 is installed, and for A quasi-tested rotary body 2, an eddy current sensor 4 to measure the comprehensive runout of the measured rotary body surface, and a Hall sensor 5 aimed at the measured rotary body 2 to obtain the rotation angle of the measured rotary body 2; The measured rotating body 2 is provided with a mark 21 that can be recognized by the Hall sensor 5; the laser displacement sensor 3, the eddy current sensor 4 and the Hall sensor 5 are all connected to the processor, and the processing The electrical runout is obtained by subtracting the relative moving distance from the comprehensive runout of the device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com