Wafer scanning detection location method

A scanning detection and positioning method technology, applied in the optical field, can solve the problems of positioning error, built-in time difference, etc., and achieve the effect of avoiding data stream storage, ensuring the realization of online detection, and preventing positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An embodiment of the present application provides a wafer scanning detection and positioning method, wherein the wafer is fixed on a mobile platform, and the mobile platform drives the wafer to move.

[0031] When the mobile platform starts to move, the positioning component is in working state.

[0032] After the mobile platform moves to a stable state, the sampling component starts to collect scattered light signals.

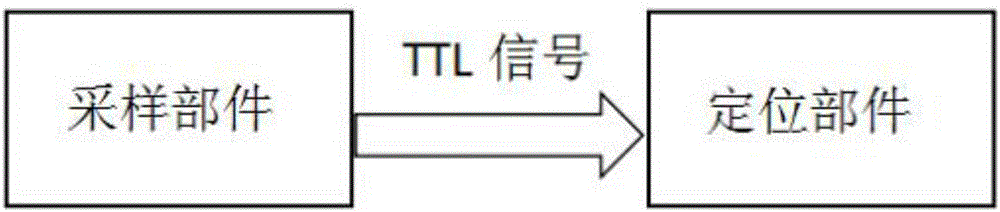

[0033] When the scattered light signal starts to be collected, the sampling component sends a TTL signal to the signal collection port connected to the positioning component.

[0034] After the signal collection port receives the TTL signal, the positioning component collects positioning information according to a predetermined frequency.

[0035] Wherein, the positioning component is a grating ruler built in the mobile platform.

[0036] The sampling component includes a photodetector, an analog-to-digital conversion card, and a data acquisition card...

Embodiment 2

[0043] An embodiment of the present application provides a wafer scanning detection positioning method, including the synchronization of the acquisition start time of the positioning component and the sampling component, and the synchronization of the sampling interval of the positioning component and the sampling component.

[0044] Synchronization of the acquisition start time of the positioning component and the sampling component: the wafer is fixed on the mobile platform, and the mobile platform drives the wafer to move; when the mobile platform starts to move, the positioning component is in a working state; the After the mobile platform moves to a stable state, the sampling part starts to collect scattered light signals; when the scattered light signals start to collect, the sampling part sends a TTL signal to the signal collection port connected to the positioning part; the signal collection After the port receives the TTL signal, the positioning component collects posi...

Embodiment 3

[0056] An embodiment of the present application provides a wafer scanning detection and positioning method, which can be divided into three aspects: synchronous sampling, trajectory positioning, and classification and storage of positioning information based on scattered light signals.

[0057] 1. Synchronous sampling:

[0058] Synchronous sampling includes the synchronization of the acquisition start time of the positioning component and the sampling component, and the synchronization of the sampling interval of the positioning component and the sampling component.

[0059] Synchronization of the acquisition start time of the positioning component and the sampling component: the wafer is fixed on the mobile platform, and the mobile platform drives the wafer to move; when the mobile platform starts to move, the positioning component is in working condition; the After the mobile platform moves to a stable state, the sampling part starts to collect scattered light signals; while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com