Intermittent delivery device and method of film

A conveying device and film technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of large inertia and limited film conveying speed, and achieve the effect of increasing conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

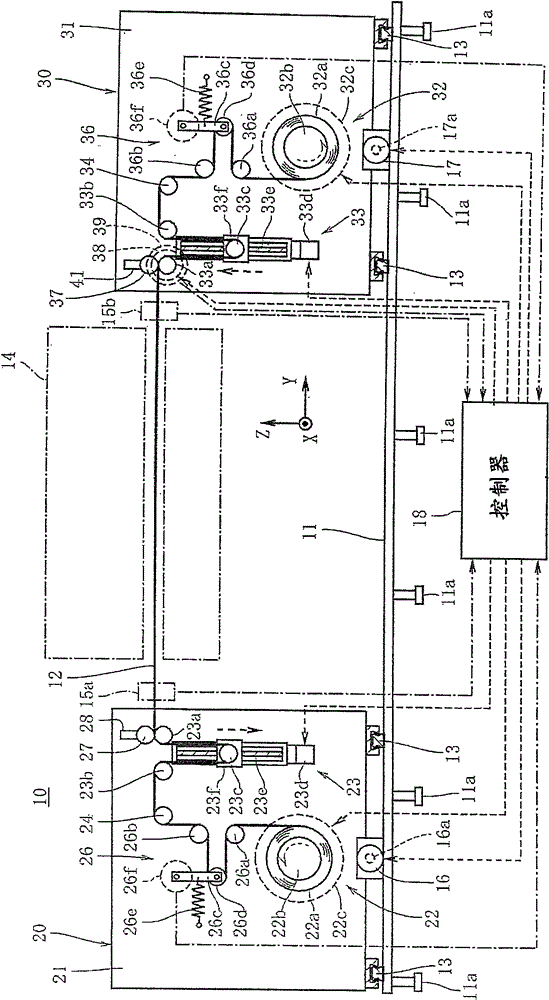

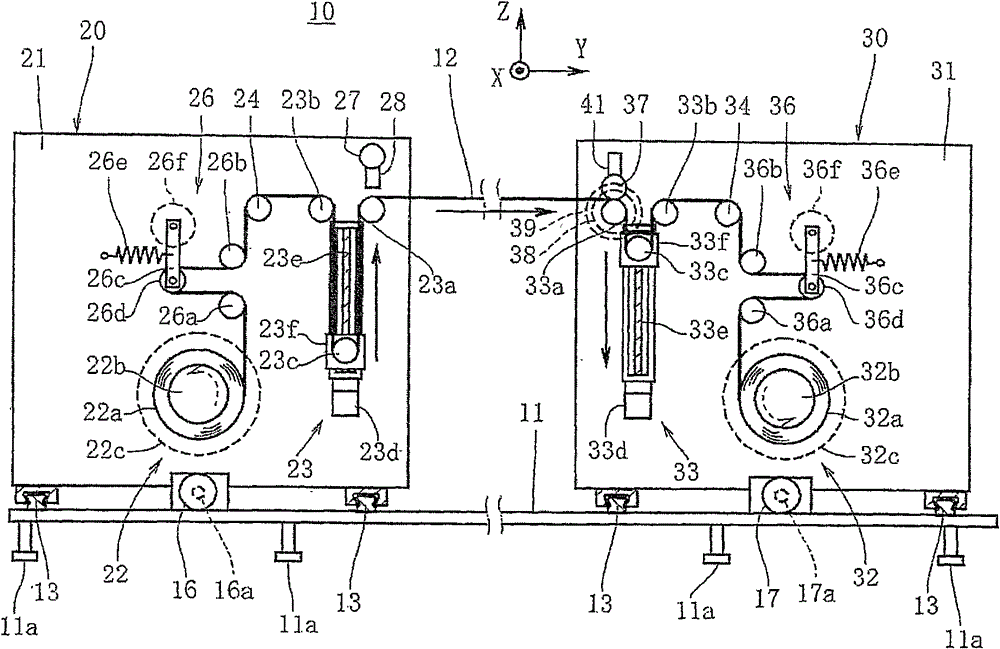

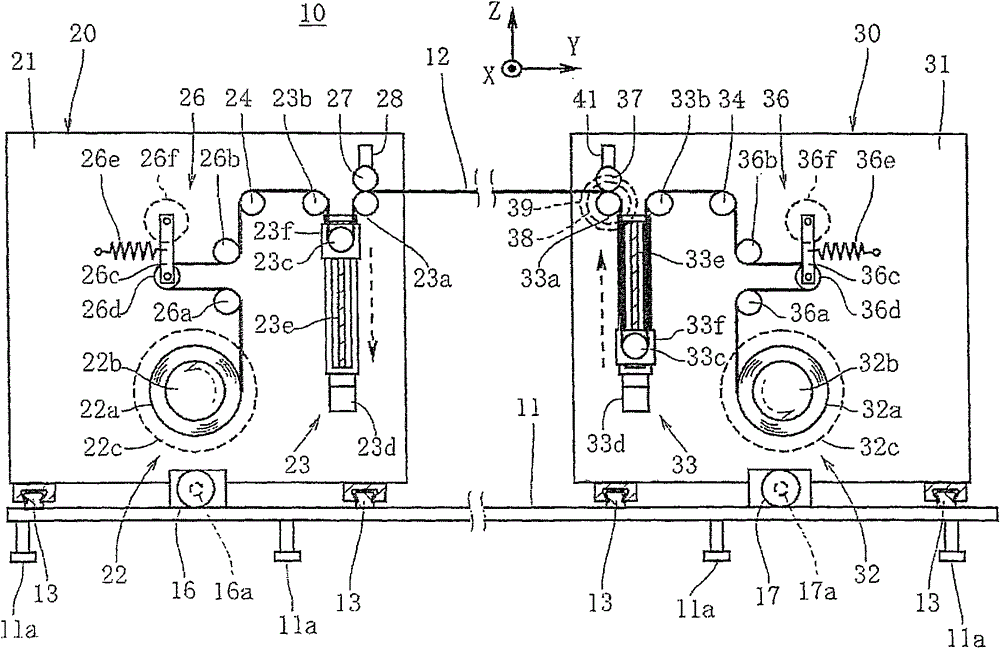

[0024] figure 1 The intermittent feeding device 10 of the film of the present invention is shown in . exist figure 1 The X, Y, and Z axes are set to be perpendicular to each other, the X axis is set to extend in a roughly horizontal front-rear direction, the Y axis is set to extend in a roughly horizontal horizontal direction, and the Z axis is set to extend in a vertical direction to illustrate this The configuration of the intermittent conveying device 10. The intermittent conveying device 10 of the present invention includes: a lead-out device 20, which is arranged on one end side of an elongated horizontal base 11 extending along the Y-axis direction, for leading out a predetermined amount of film 12; a winding device 30, which Axially away from the lead-out device 20 is disposed on the other end side of the base 11 for winding a prescribed amount of fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com