Mosquito net bracket

A technology for mosquito nets and aluminum alloy brackets, applied in the bracket field, can solve the problems of inconvenient disassembly, easy shaking, and the installer's hand rubbing injury, etc., and achieves the effects of improving stability, strong flexibility, and easy transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

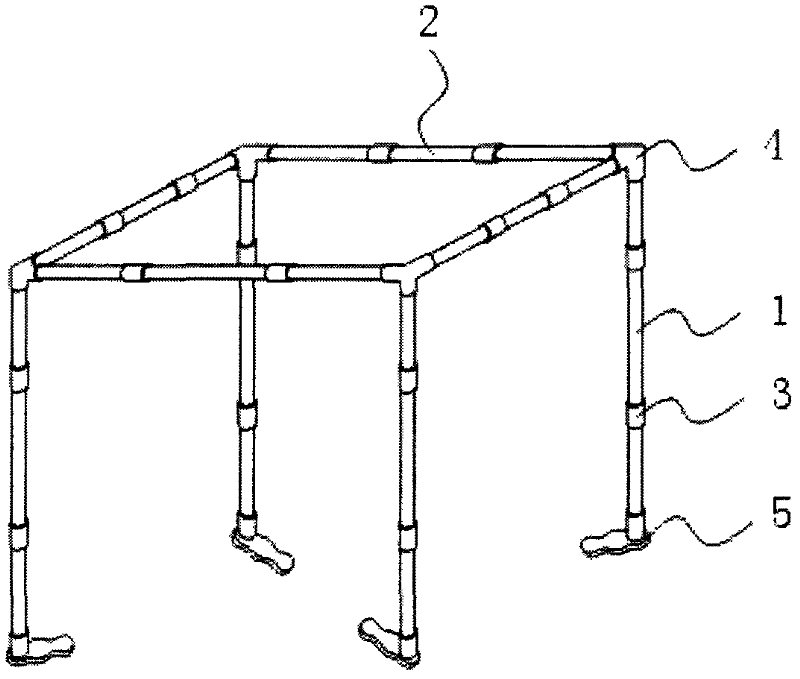

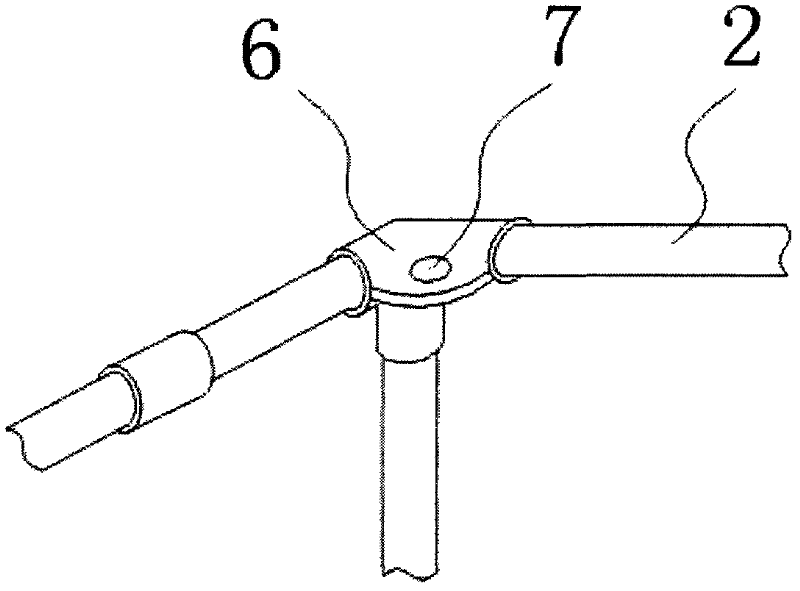

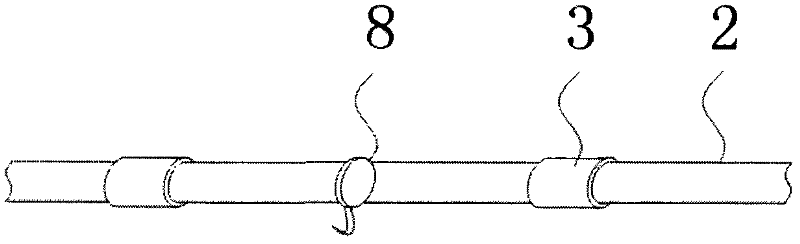

[0017] Example 1, such as figure 1 Shown, a kind of mosquito net support comprises a canopy frame and four vertical support bars 1 supporting the whole canopy frame, and the canopy frame is a square closed structure surrounded by four canopy poles 2 . The canopy pole 2 and the vertical support pole 1 include three connecting rods, which are connected as a whole by threaded pipes 3. Threaded holes are provided at both ends of the threaded pipe 3, and the two ends of the canopy pole 2 There are external threads, and the canopy pole 2 is connected to a complete canopy pole 2 through the external thread at its end and the threaded pipe thread, and the external threads at both ends of the canopy pole 2 are respectively connected to a tee pipe 4, and It forms a closed square roof structure. The three ends of the three-way pipe 4 are all provided with threaded holes, wherein two threaded holes are respectively connected to a roof pole, 2 remaining ends are connected to a vertical su...

Embodiment 2

[0025] Embodiment 2: as Figure 4 As shown, two of the canopy poles 2 in the canopy are arc-shaped or corrugated, and a cross bar 9 is arranged between the arc-shaped canopy poles 2 . The curved or corrugated design can increase the overall ornamental value of the mosquito net bracket and meet the different needs of customers for the mosquito net bracket. Of course, it can also be designed into other shapes according to personal preferences. At the same time, the cross bar 9 between the arc-shaped roof struts 2 can also be used to hang small fans and other decorations to improve the comfort of rest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com