Sublimator

A sublimator and inner shell technology, applied in the field of sublimers, can solve the problems of affecting the sublimation speed, shortening the service life of the sublimator, large energy consumption, etc., and achieve the effects of improving energy utilization, reducing heat loss, and improving sublimation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

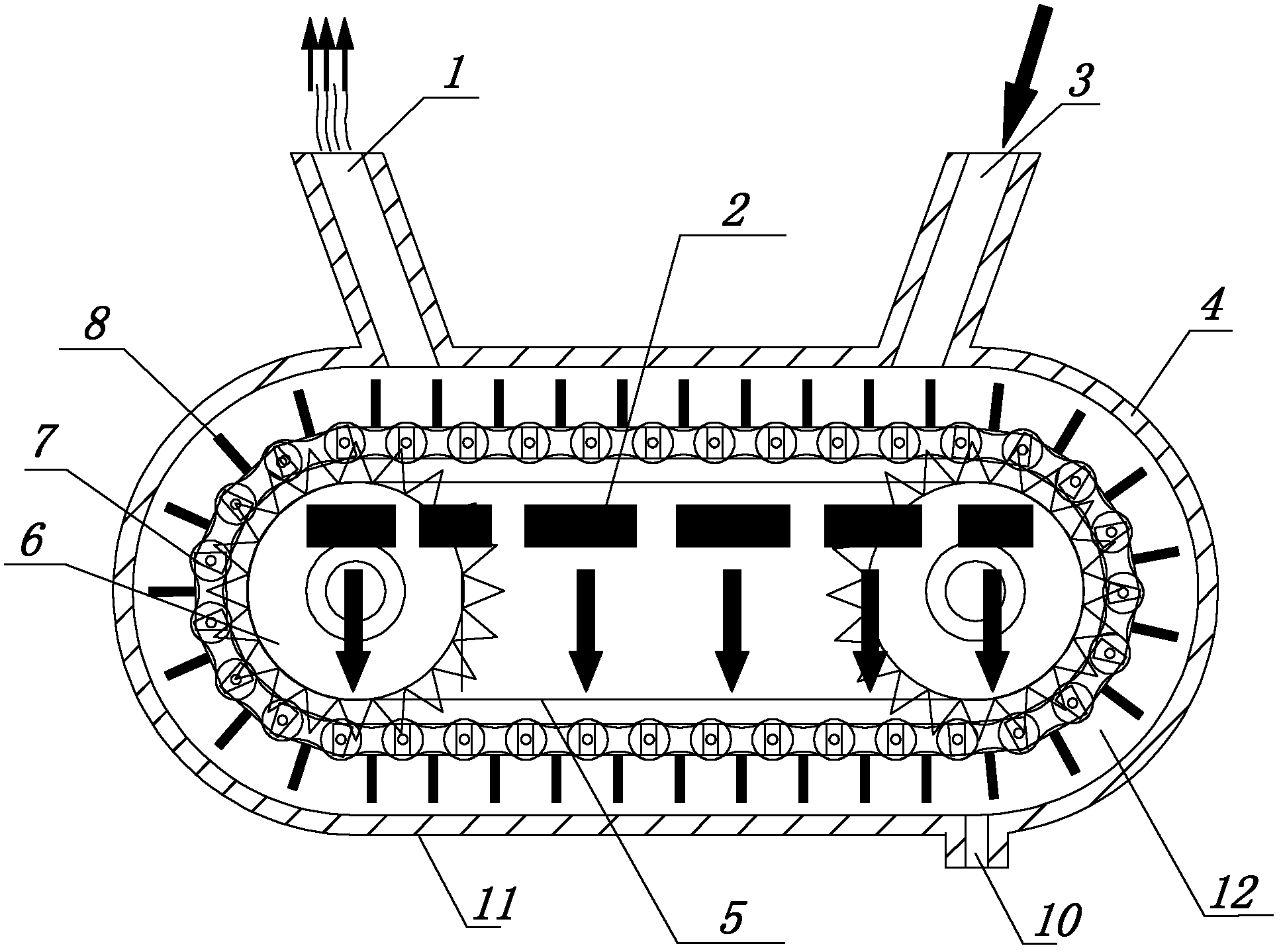

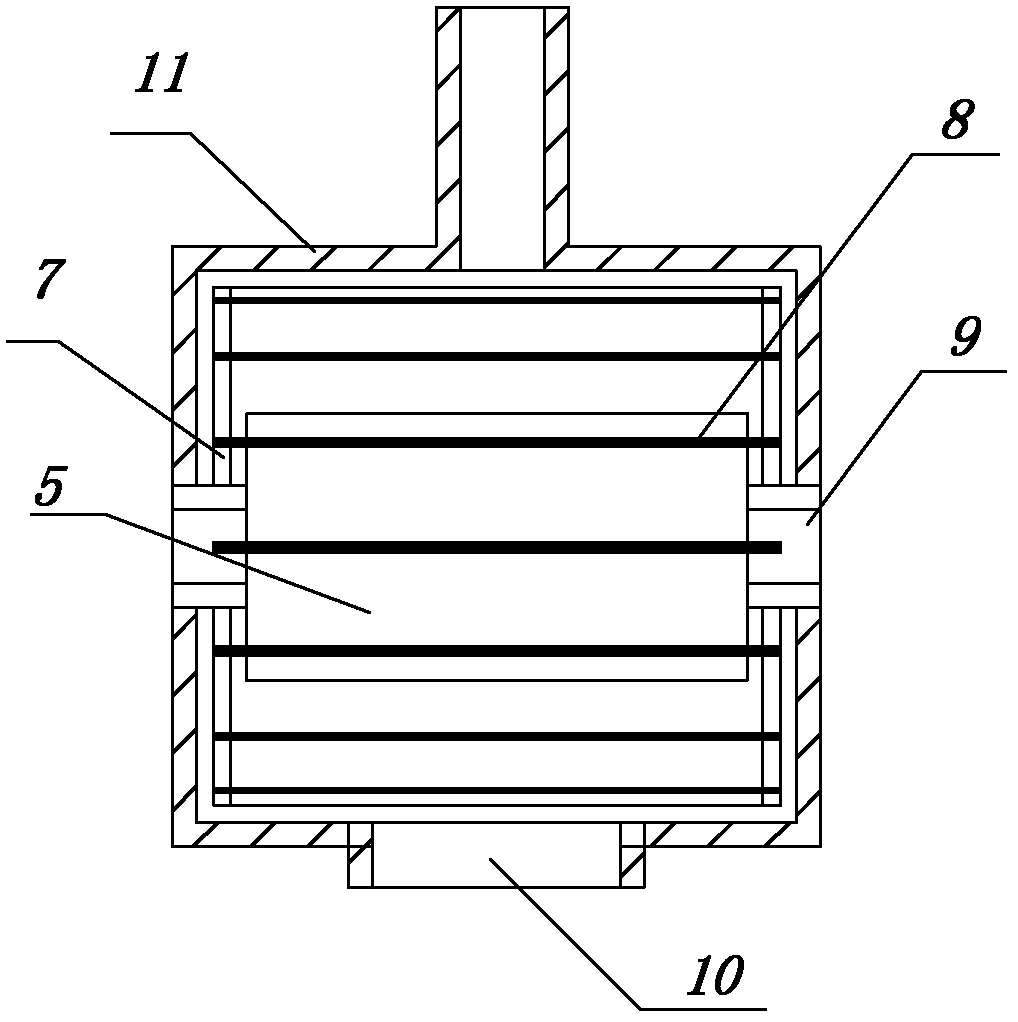

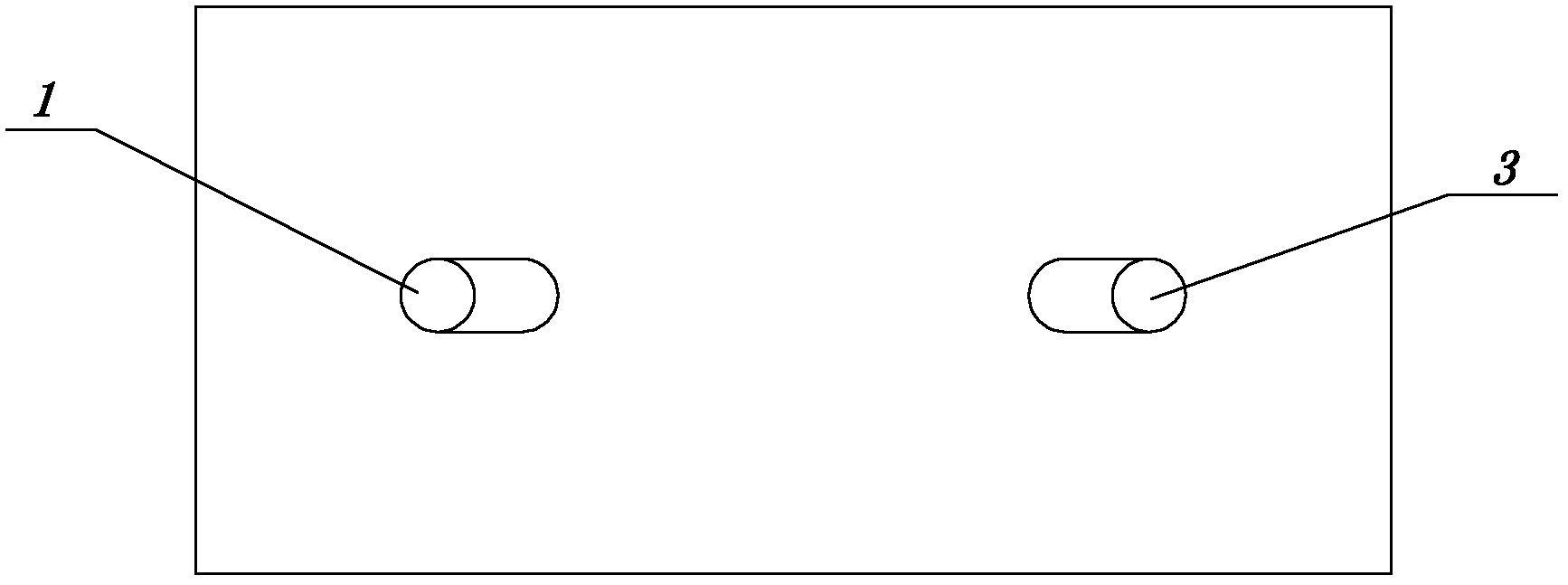

[0022] like figure 1 , figure 2 , image 3 As shown, a sublimator includes an inner shell 5 wrapping the heating element 2 and an outer shell 11 wrapping the inner shell 5. The outer shell 11 has a material inlet 3 and a material sublimation gas outlet 1, and the inner shell 5 and the outer shell 11 form a An annular passage 12 containing materials to be sublimed, and a transmission mechanism for making the materials to be sublimated flow along the annular passage is provided in the annular passage 12 . The transmission mechanism in this embodiment includes a bearing 9, a gear 6, a chain 7, and a shovel 8 for shoveling and stirring materials to be sublimated, such as figure 1 As shown, corrosion-resistant and high-temperature-resistant metal bearings 9 are respectively installed on the left and right sides of the front / rear end faces of the inner she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com