Agent-unloading device system for methanol-to-olefin reactor of fluidized bed

A fluidized bed reactor, methanol-to-olefin technology, applied in the production of hydrocarbons from oxygen-containing organic compounds, chemical instruments and methods, chemical recovery, etc. and other problems to achieve the effect of reducing production costs and improving maintenance progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

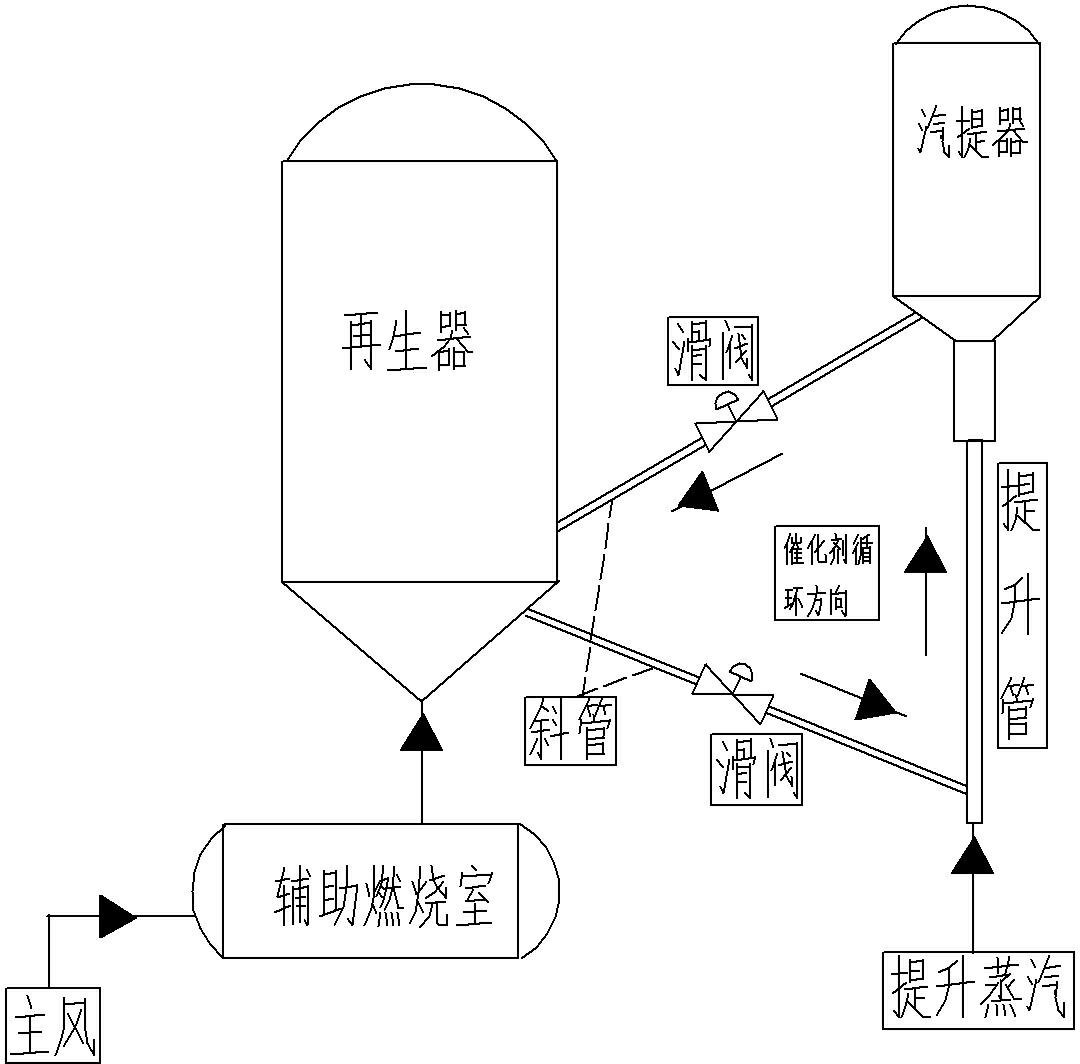

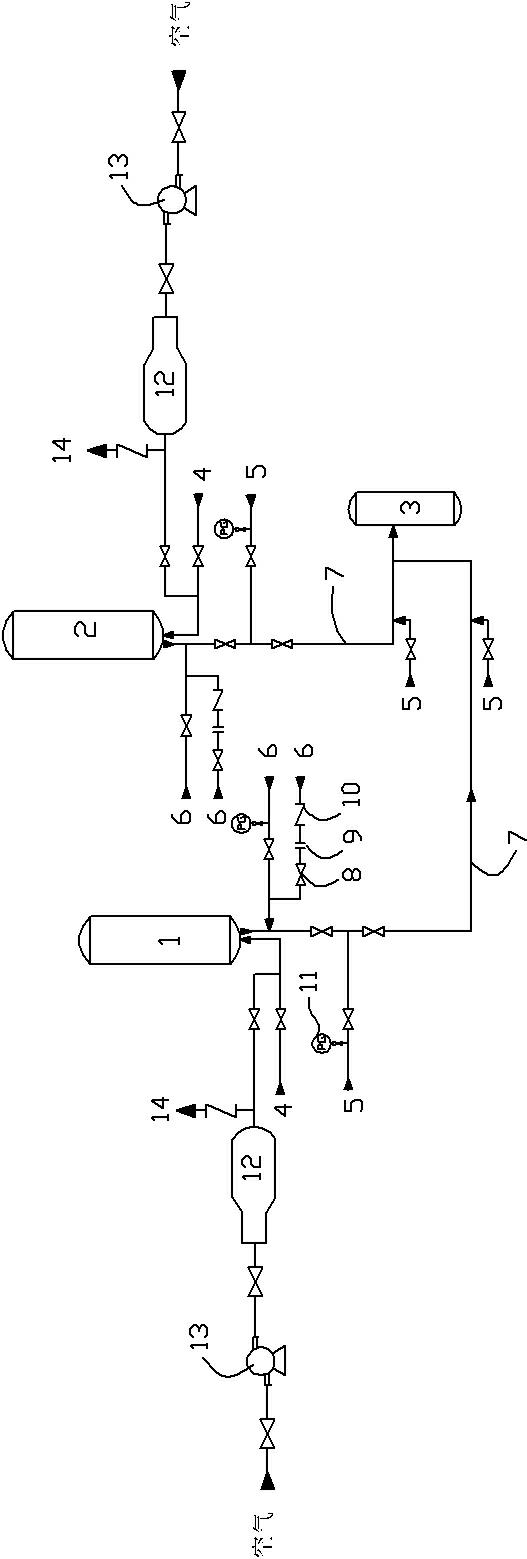

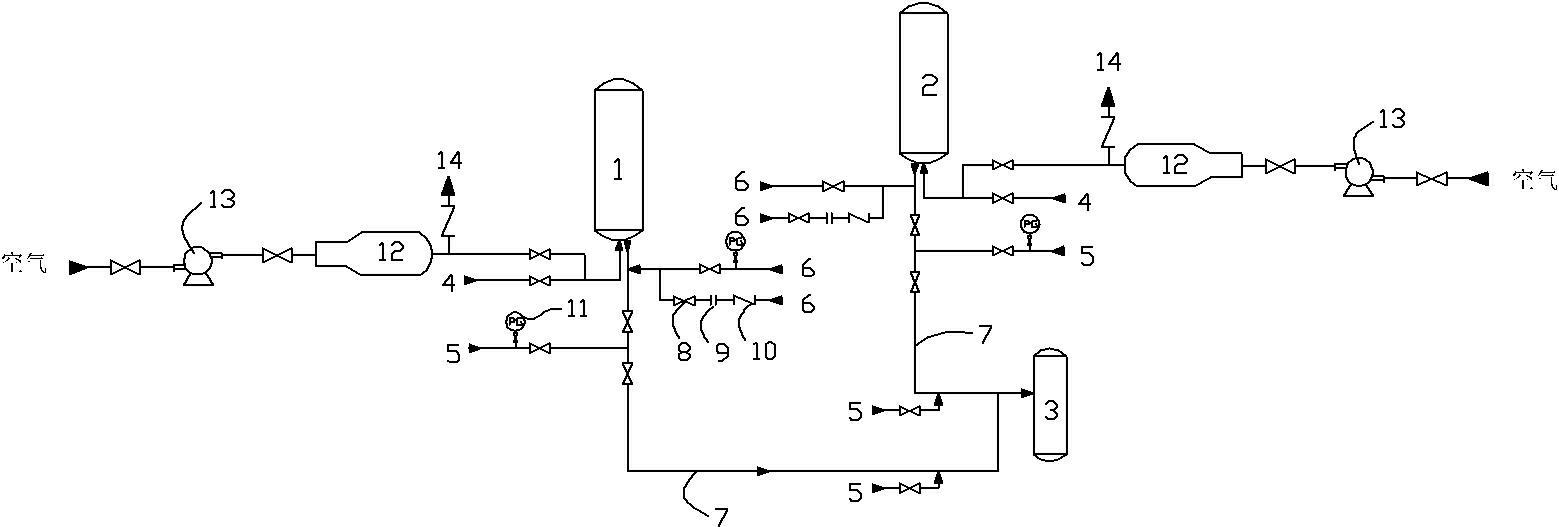

[0021] The fluidized bed methanol-to-olefins reactor discharger system of the present invention comprises a fluidized bed reaction device, and the fluidized bed reaction device includes fluidized bed reactors 1 and 2, a feed line 4 and a fluidized bed reactor. Connected catalyst regeneration cycle system, such as figure 2 , the catalyst regeneration circulation system includes a regenerator, a stripper, an inclined pipe, etc., and the bottom of the fluidized bed reactor is connected to the catalyst storage tank 3 through the unloading pipeline 7, and two groups of unloading valves are arranged on the unloading pipeline 7, and The unloading pipeline between the two groups of unloading valves is connected with an air conveying air pipeline 5, which is used to confirm that the pipeline is unblocked before unloading. The catalyst flows smoothly when unloading; the unloading pipeline between the unloading valve and the fluidized bed reactor is equipped with a flow-restricting orif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com