Novel gas-liquid two-phase annular flow liquid film mass flow measurement device and method

A mass flow, measuring device technology, applied in the direction of volume flow measuring device, measuring device, liquid/fluid solid measurement, etc., can solve the problems of inaccurate measurement, slow response speed, etc., to achieve accurate measurement, avoid errors, and accurately take out and metered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

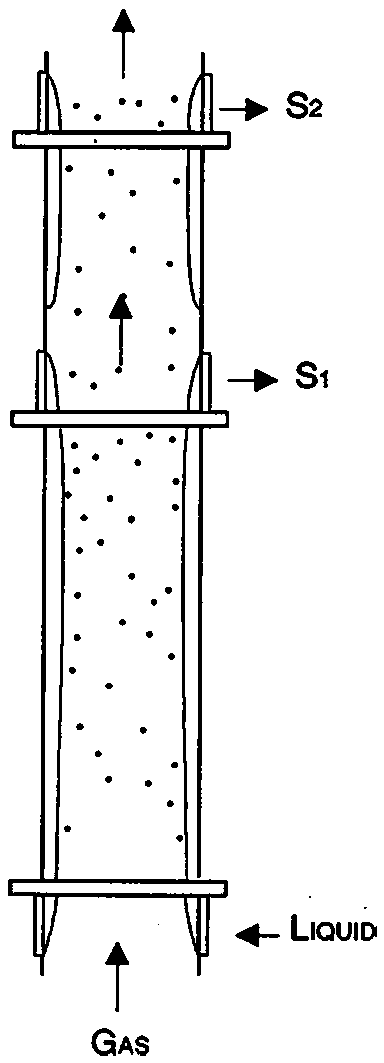

[0037] Example 1, a novel gas-liquid two-phase annular flow liquid film mass flow measurement device.

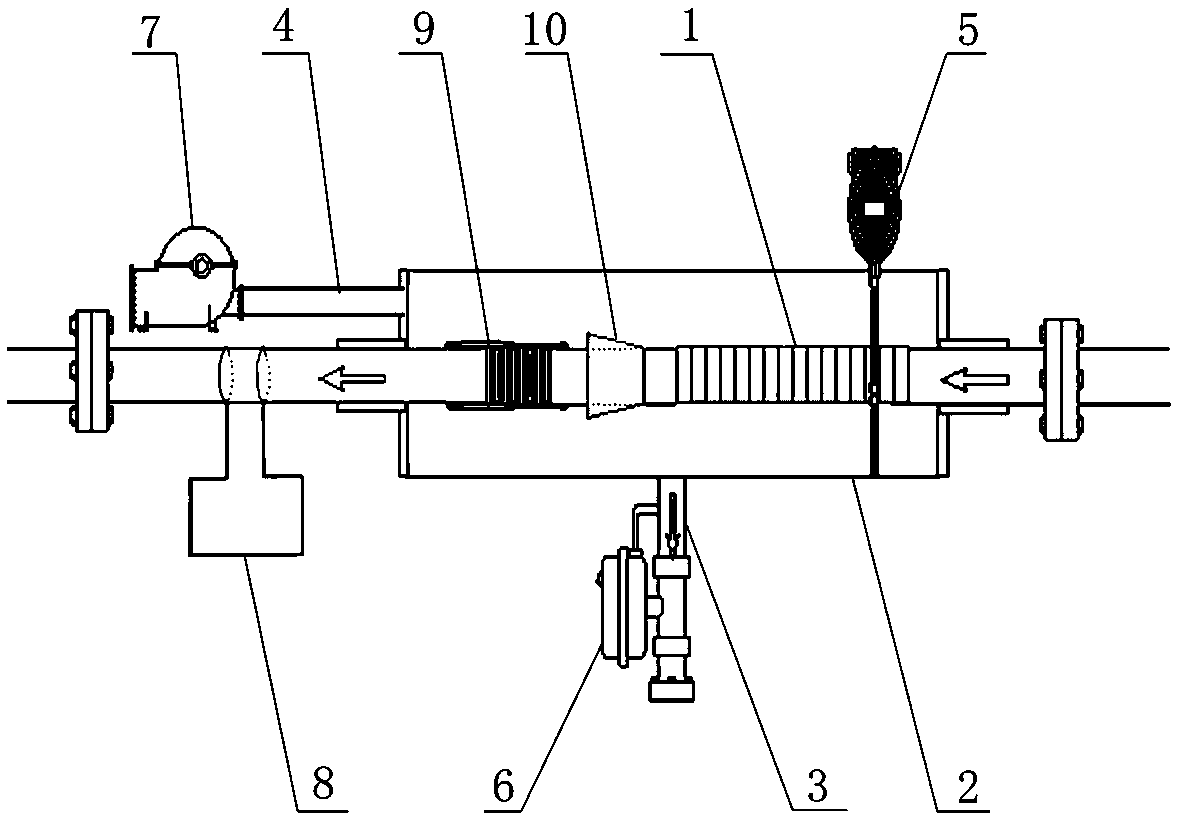

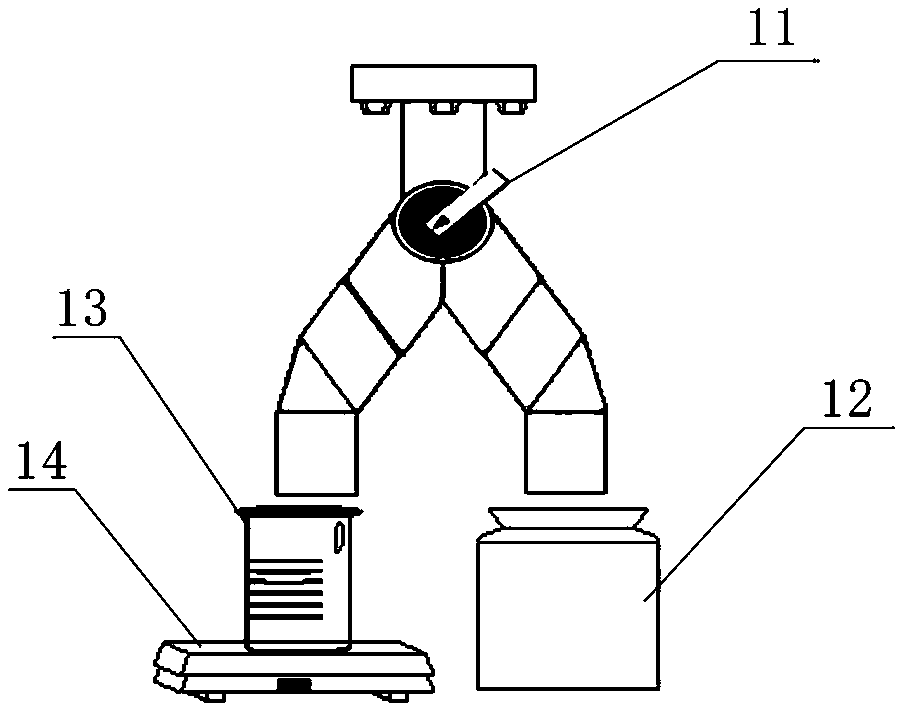

[0038] like figure 2 As shown, the new gas-liquid two-phase annular flow liquid film mass flow measurement device provided by the present invention includes a liquid film take-out and collection mechanism, a liquid film detection mechanism, a mass flow measurement mechanism and an automatic control system.

[0039] The liquid film take-out and collection mechanism is used to realize the take-out and collection of the liquid film in the gas-liquid two-phase annular flow. The liquid film taking and collecting mechanism includes a porous permeable tube 1 , an expansion tube 10 , an electric telescopic tube 9 , a liquid storage container 2 and an air pump 7 . The liquid storage container 2 is a container with a cuboid structure made of plexiglass, which is used to store the liquid film taken out from the pipeline. In the present invention, the pipeline for taking out the liqu...

Embodiment 2

[0049] Example 2, a novel gas-liquid two-phase annular flow liquid film mass flow measurement method.

[0050] The novel gas-liquid two-phase annular flow liquid film mass flow measurement method provided by the present invention comprises the following steps:

[0051]a. Build a new gas-liquid two-phase annular flow liquid film mass flow measurement device. For the specific introduction of the liquid film mass flow measurement device, refer to the description in Embodiment 1, which will not be repeated here.

[0052] b. Feed a stable gas-liquid two-phase annular flow into the porous permeation tube; open the electric control valve, and the automatic control system controls the commutator to make the liquid film flow into the waste liquid tank.

[0053] c. Close the electric control valve, set the initial gap between the electric telescopic tube and the expansion tube (the initial gap can be set to zero or 1mm), turn on the air pump to adjust the pressure difference between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com