High-fidelity shark-imitating anti-drag structure capable of slowly releasing drag reducer instantly and manufacturing method thereof

A production method and shark-imitating technology, applied in the field of bionics, can solve the problems that the release of drag reducing agent cannot be automatically controlled according to the speed, the release of drag reducing agent is not easy, and the efficiency of drag reduction needs to be improved, so as to improve high-speed maneuverability and reduce Effects of sailing resistance and high-efficiency coupling drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

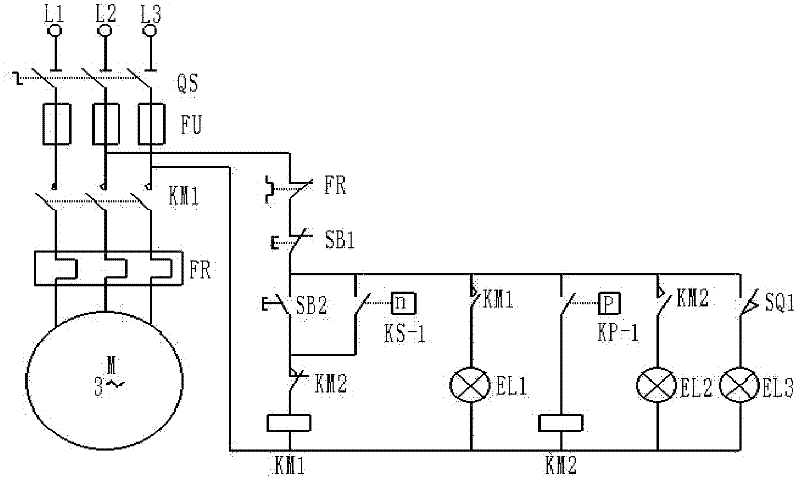

[0064] Embodiment 1: The control module 9 in the slow-release electro-hydraulic control system can adopt such image 3 shown in the circuit diagram. Correspond the speed of the power rotating device on the application object to its actual sailing speed, and set the power speed corresponding to the application object at a certain speed (such as 40kph) as the set value of the speed relay (can be set arbitrarily according to the sailing speed) .

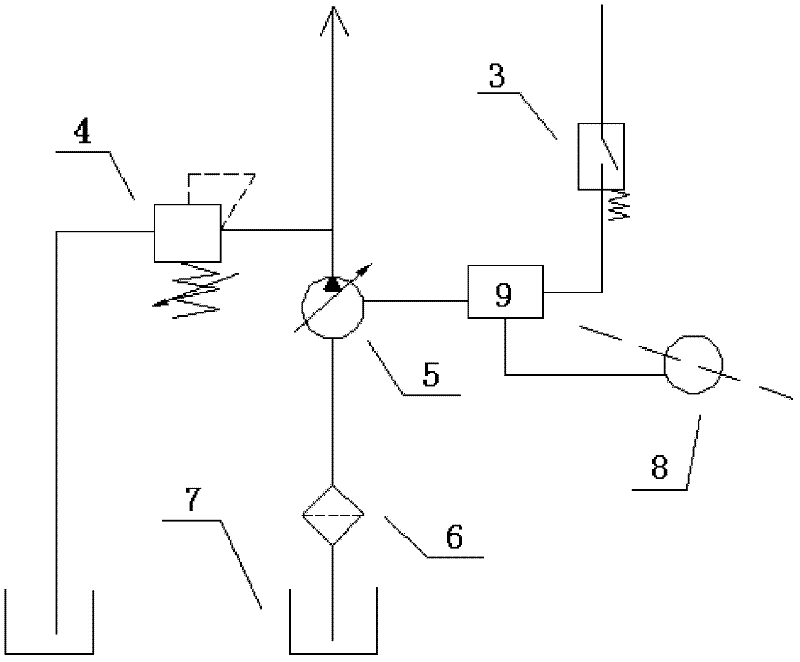

[0065] When the speed relay 8 detects that the speed information is higher than a set value, the KS-1 in the action control module of the speed relay 8 is closed, the contactor coil KM1 is energized, the normally open contact KM1 is closed, and the motor M drives the hydraulic pump 5 to work. The normally open contact KM1 in the control module 9 is closed, and the indicator light EL1 is on, indicating that the hydraulic pump 5 is working, pumping the drag reducing agent into the drag reducing agent delivery channel 12, and then passing...

Embodiment approach 2

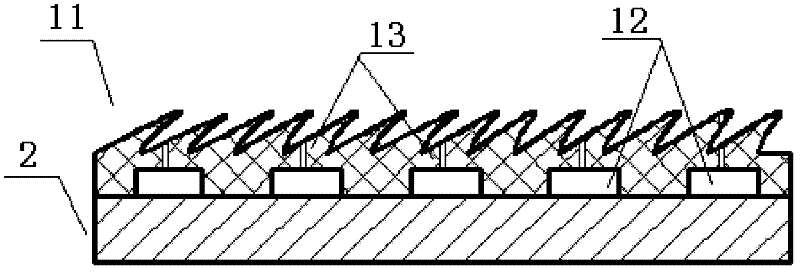

[0069] Embodiment 2: The scaled skin 1 made by the manufacturing method of the present invention is applied to the surface of the application object 2 in contact with liquid such as a micro underwater robot, a micro submarine, a torpedo, and the like. Such as figure 1 As shown, the scaly skin 1 is bonded to the outer surface of the application object 2 with waterproof superglue, the scaly side of the scaly skin 1 faces outward, and the side containing the drag reducing agent delivery channel 12 is close to the application object 2 the outer surface. The direction of the scale groove on the scaly surface is consistent with the direction of flowing water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com