Air seal and manufacturing method thereof

A technology of air sealing body and manufacturing method, which is applied in the direction of preventing mechanical damage to containers, containers, transportation and packaging, etc., can solve the problems of restricting the scope of application of air sealing body structure, lack of air sealing body, and shortened length of air column, etc., to achieve The effect of increasing the scope of application and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

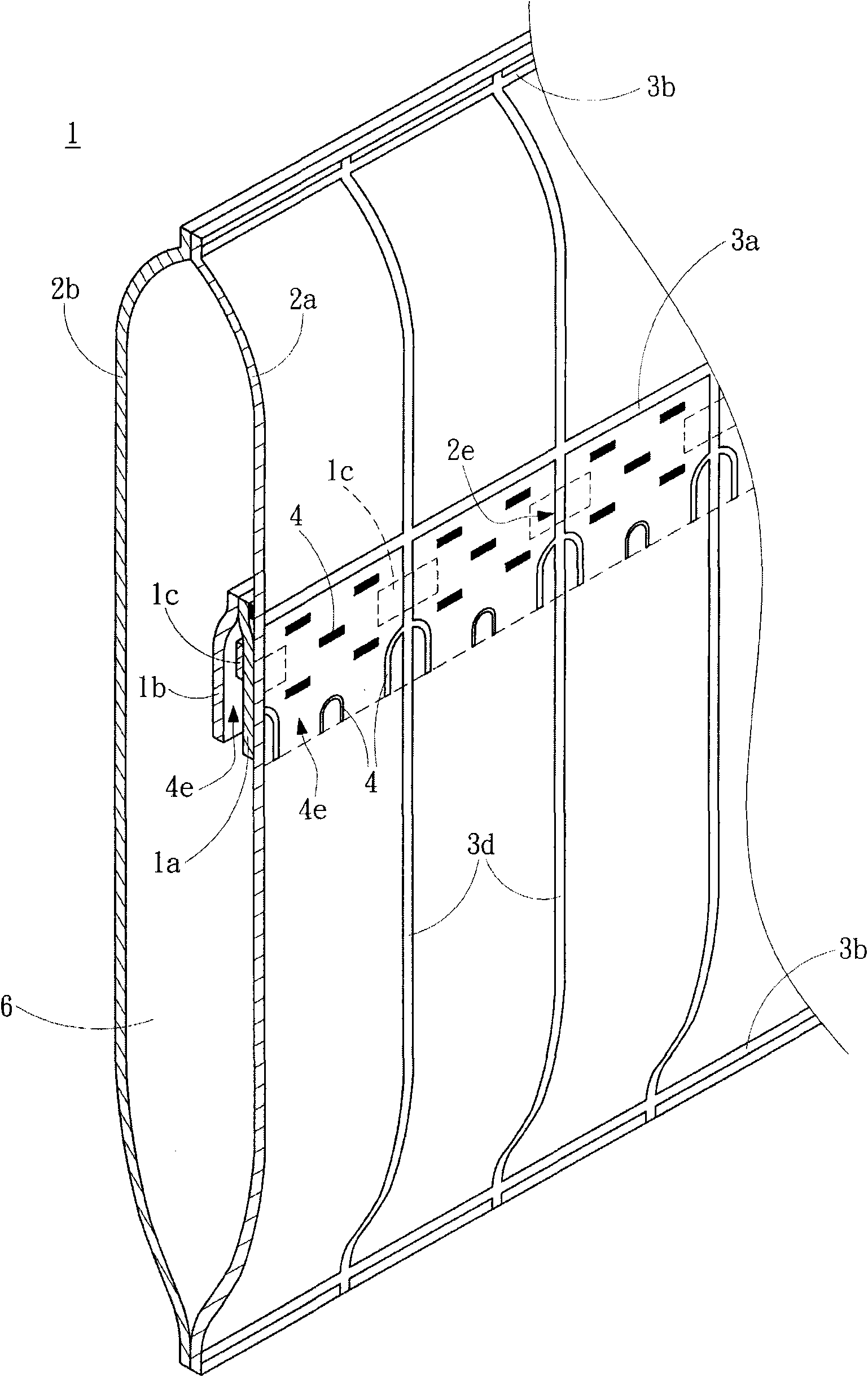

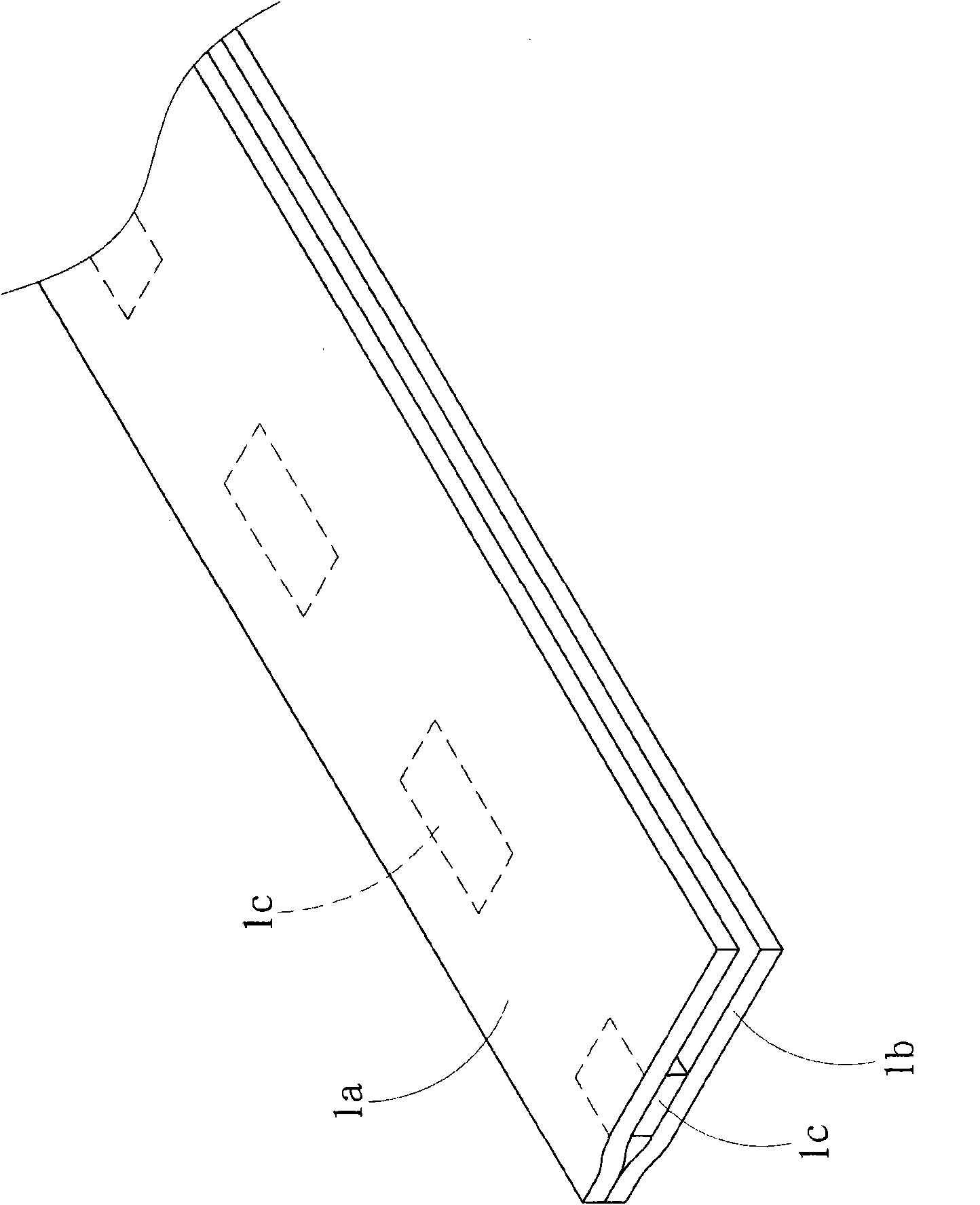

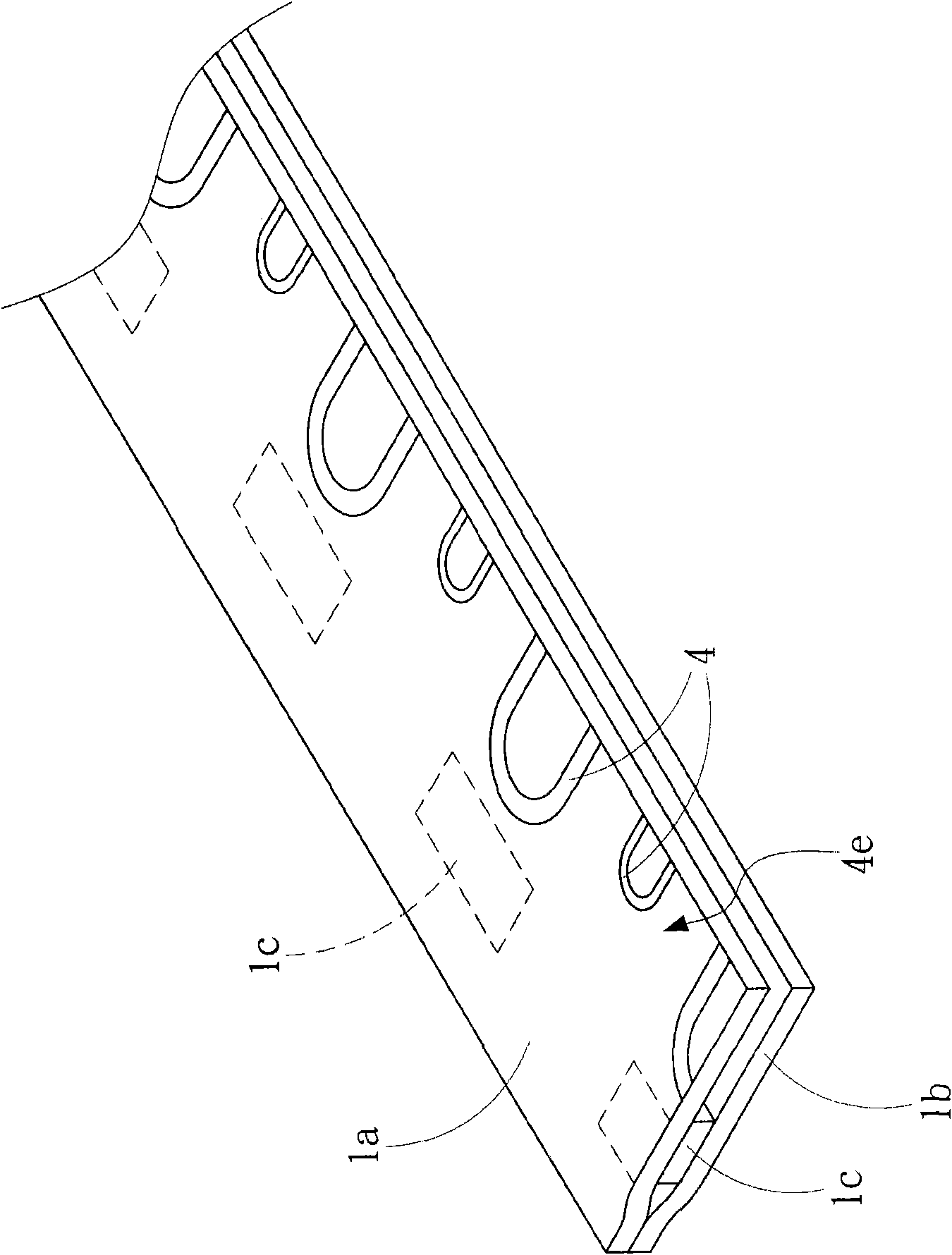

[0040] see figure 1 , Figure 2A , Figure 2B , Figure 2C and Figure 2D , respectively represent the air sealing body with changeable air valve position according to the specific embodiment of the present invention.

[0041] In a specific embodiment of the present invention, the air-tight body 1 with a changeable air valve position includes: a first outer film 2a and a second outer film 2b, two inner films 1a and 1b, a first transverse heat-sealing line 3a, multiple A second transverse heat-sealing line 3b, a plurality of longitudinal heat-sealing lines 3d, a plurality of air columns 6, and a plurality of air inlets 2e.

[0042] Wherein, the first outer membrane 2a is a strip-shaped membrane.

[0043] The two inner membranes 1a and 1b are el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com