A kind of semiconductor rectifier and its manufacturing method

A rectifier and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the series resistance of the conductive channel, low doping concentration of the epitaxial layer, and high forward conduction voltage drop, etc., to achieve improved The effect of conductive channel density, reducing series resistance, and reducing forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

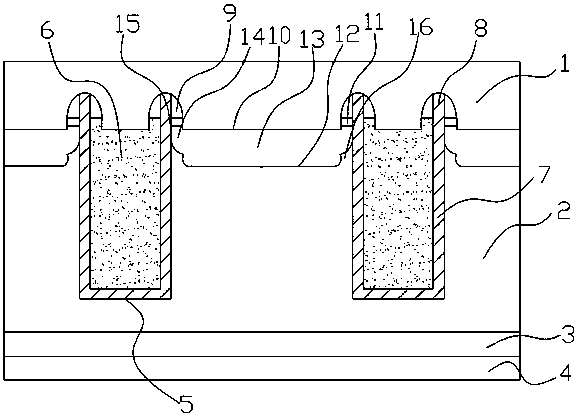

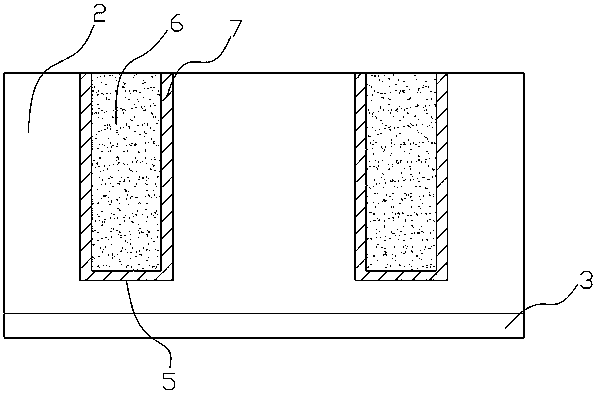

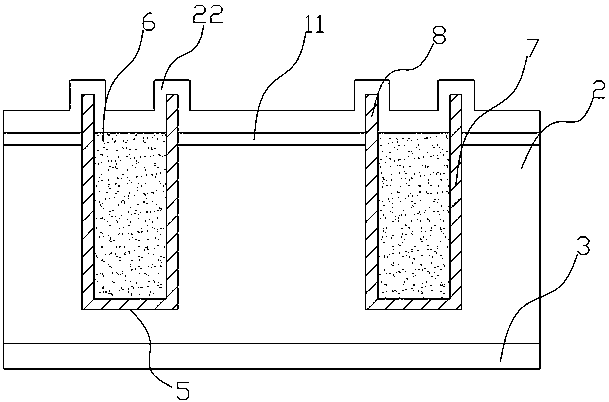

[0046] Such as figure 1 A semiconductor rectifier shown is composed of an anode metal layer 1, a lightly doped epitaxial layer 2 of the first conductivity type, a heavily doped single crystal silicon substrate 3 of the first conductivity type, and a cathode metal layer 4 from top to bottom. Composition, the upper part of the epitaxial layer is horizontally arranged with several first grooves 5 at intervals, the first grooves are filled with conductive polysilicon 6, and an isolation layer 7 is arranged between the conductive polysilicon and the first grooves, and the isolation layer protrudes upwards to form a dielectric wall 8. Conductive polysilicon sidewalls 9 of the first conductivity type are provided on both sides of the dielectric wall, and the area between the upper part of the epitaxial layer and the conductive polysilicon sidewall outside the dielectric wall forms a second trench 10. The conductive polysilicon sidewall located outside the dielectric wall The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com