Perpendicular stacking type automatic stereoscopic warehouse cabinet

A three-dimensional, storage cabinet technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of unfavorable promotion of vertical automatic storage rails, complex processing technology, and difficulty in improving speed, so as to reduce the overall size and reduce the occupied area area, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

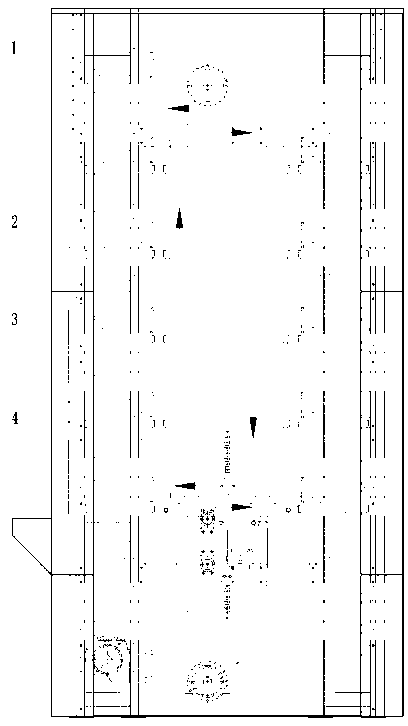

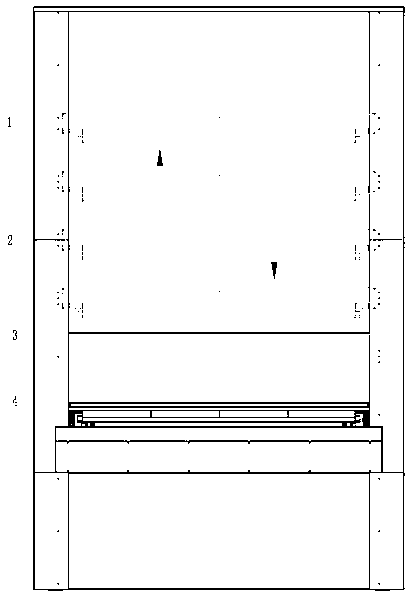

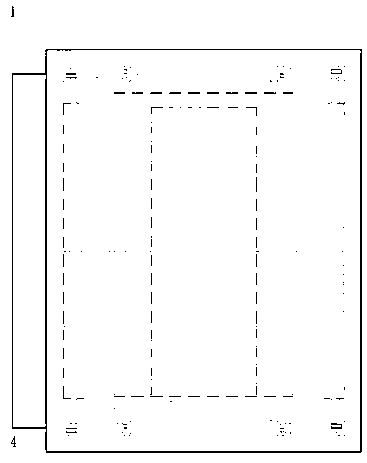

[0014] Such as Figure 1 to Figure 3 As shown, a kind of vertical stacking automatic three-dimensional storage cabinet provided by the present invention comprises a storage cabinet body 1, an access port 3 is provided on the storage cabinet body 1, and an access port workbench is provided at the access port 3 4. It is characterized in that: there are two rows of vertically arranged shelf sheet groups in the front and rear of the cabinet body 1, and the left article box fixing seat 23 and the right article box fixing seat 24 are respectively provided on both sides of the two rows of shelf sheet groups. The article box 2 that is used to shelve goods is respectively placed on the left article box fixed seat 23 and the right article box fixed seat 24, and the upper and lower parts of the two rows of shelf sheet groups are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com