Gas diffusion silencer

A muffler and gas technology, applied in the direction of sound-generating equipment, instruments, blast furnace parts, etc., can solve the problems of difficult replacement of sound-absorbing sheets, inconvenient transportation and installation, heavy weight, etc.

Inactive Publication Date: 2012-03-21

NANTONG SHENDONG METALLURGICAL MACHINERY

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing blast furnace gas diffuser mufflers generally adopt an integral structure, and the sound-absorbing sheet is installed in the casing of the gas diffuser muffler. Since the muffler is installed at a height of tens of meters, it is difficult to replace the sound-absorbing sheet afterwards; in addition, the integral muffler, Very heavy and difficult to transport and install

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

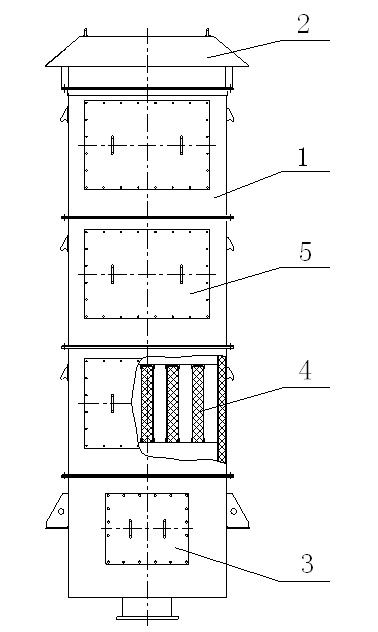

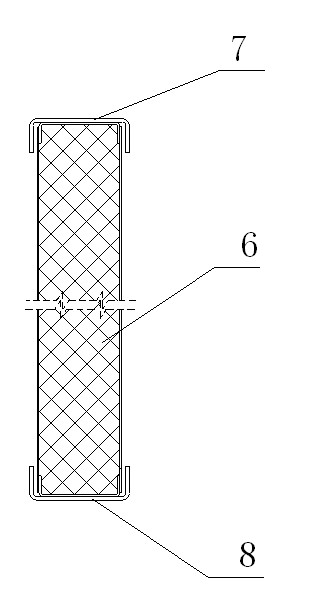

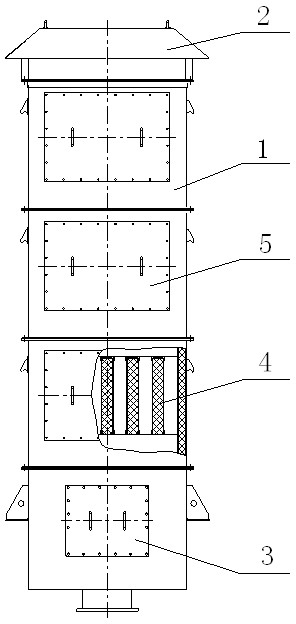

The invention discloses a gas diffusion silencer, which comprises a shell, a diffusion cap arranged at the top of the shell and an ash discharge door arranged at the bottom of the shell, wherein the shell is divided into multiple sections, a plurality of movable sound absorption sheets are arranged in the shell sections, and sound absorption sheet changing doors are arranged on the shell sections outside the movable sound absorption sheets. The gas diffusion silencer has the advantages that: the integral silencer is sectioned, and the original silencer of several tons is split into small components of hundreds of kilograms, so that the silencer is conveniently carried to the top of a blast furnace; and the internal sound absorption sheets are designed into the movable sound absorption sheets, so that the internal sound absorption sheets can be changed without integral decomposition.

Description

technical field [0001] The invention relates to a muffler, in particular to a gas dispersing muffler. Background technique [0002] Existing blast furnace gas diffuser mufflers generally adopt an integral structure, and the sound-absorbing sheet is installed in the casing of the gas diffuser muffler. Since the muffler is installed at a height of tens of meters, it is difficult to replace the sound-absorbing sheet afterwards; in addition, the integral muffler, The weight is very heavy, which is not convenient for transportation and installation. Therefore, it is necessary to provide a new technical solution to solve the above problems. Contents of the invention [0003] The object of the present invention is to provide a gas dissipation muffler with easy replacement of sound-absorbing sheets and light structure. [0004] The technical scheme adopted in the present invention: [0005] The gas diffuser muffler consists of a shell, a release cap on the top of the shell and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21B7/00G10K11/16

Inventor 余红辉陈永新沈冬林

Owner NANTONG SHENDONG METALLURGICAL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com