High-altitude operation equipment based on mooring unmanned aerial vehicle and control method thereof

A high-altitude operation and unmanned aerial vehicle technology, applied in the field of high-altitude operations, can solve the problems of time-consuming and labor-intensive work, safety hazards of high-altitude personnel, etc., and achieve the effect of improving the safety factor, reducing the frequency of climbing high places, and reducing the load of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

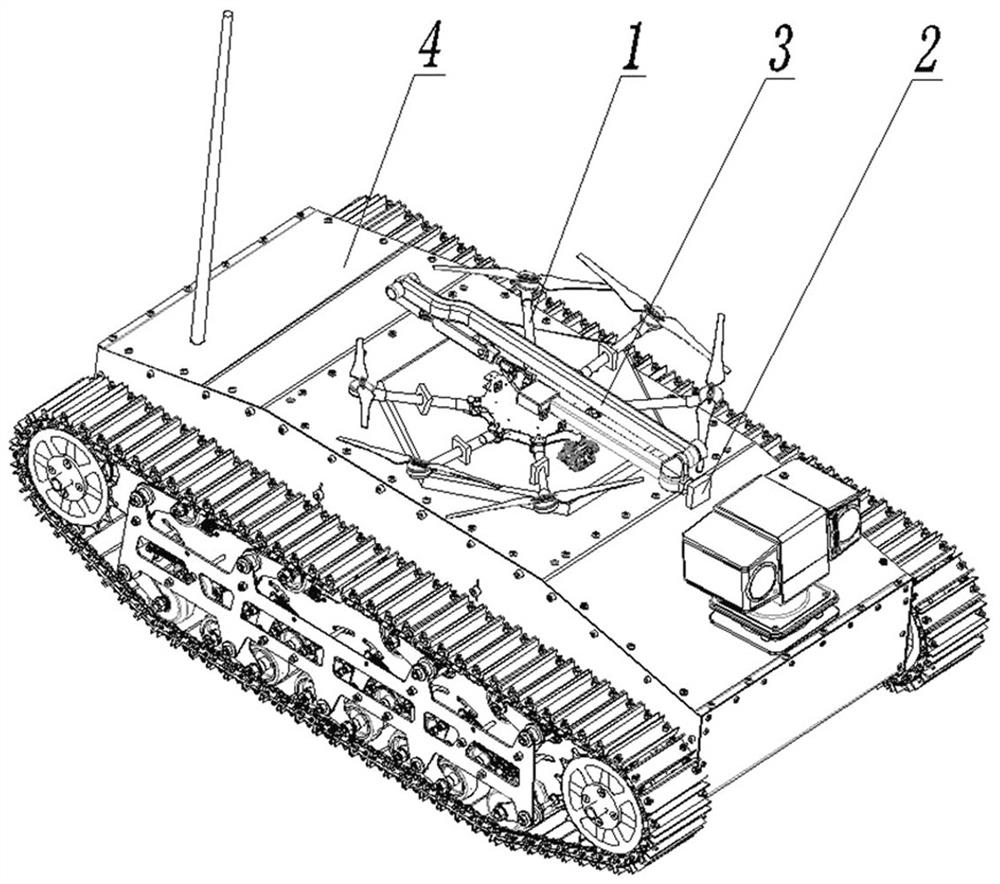

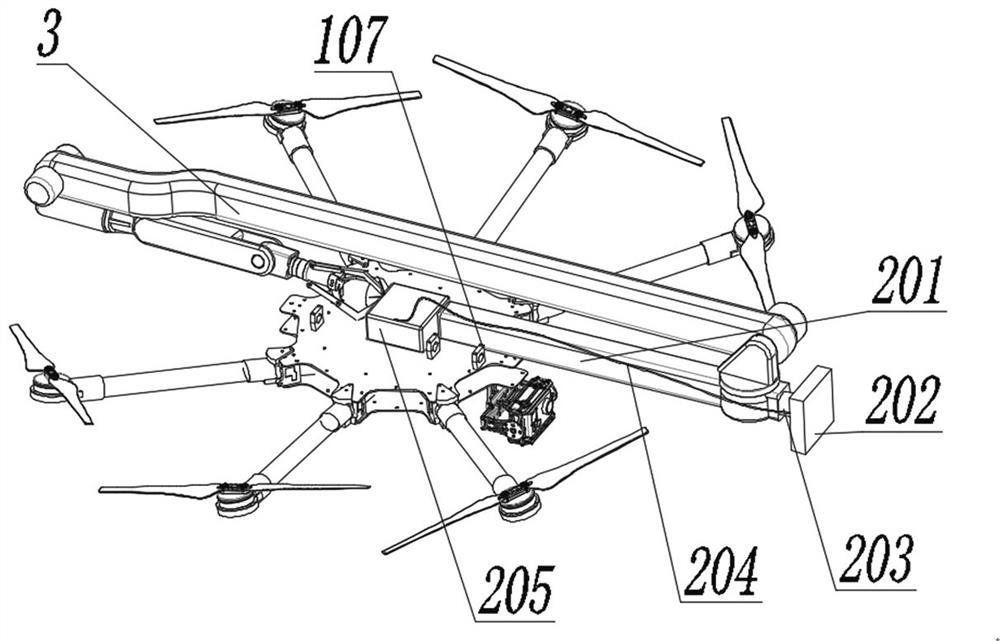

[0031] The aerial work equipment based on tethered drones mainly includes a tethered drone 1, an electronically controlled suction cup assembly 2, a six-axis robot 3 and a ground support vehicle 4.

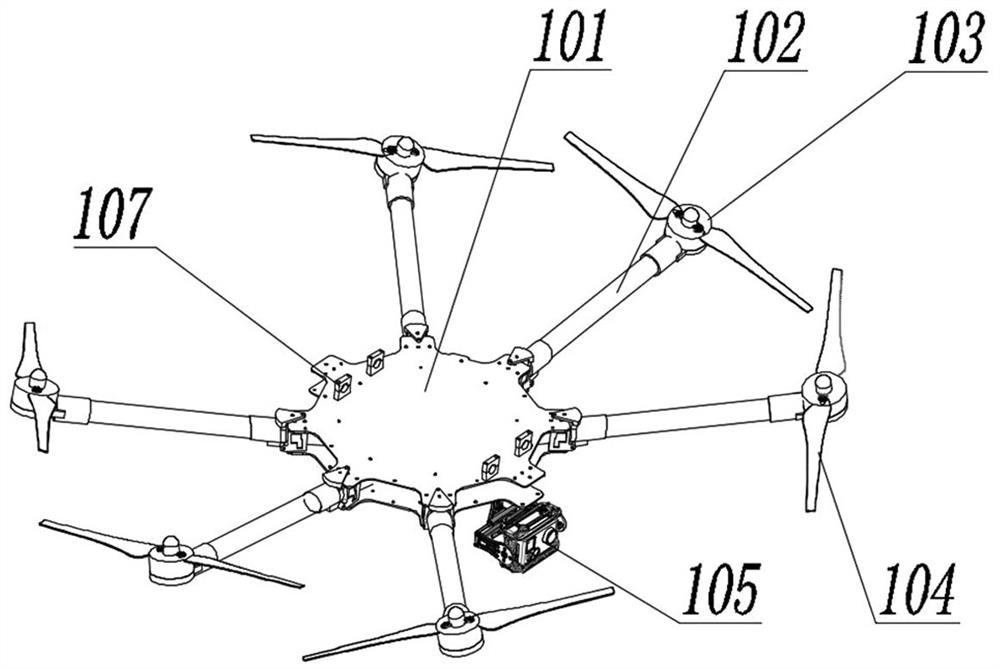

[0032] The tethered drone 1 includes a drone body 101 , a rotor connecting rod 102 , a brushless motor 103 , a paddle 104 , a pan-tilt camera 105 , a cable slot 106 and a fixing buckle 107 .

[0033] The UAV body 101 has a flat octagonal structure, and a central controller is arranged in the body of the UAV body 101 to tether the UAV's flight / attitude control, video image acquisition, power supply management, remote control, etc. Wireless communication is completed in the central controller. Each of the six edges of the drone body 101 is connected with a rotor connecting rod 102, 6 in total. Each rotor link 102 is connected with the drone body 101 by a hinge, and when the tethered drone 1 is not working, the rotor link 102 can be folded to save space for high-altitude work. Abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com