Reinforced concrete cast-in-place frame structure of a building

A reinforced concrete and frame structure technology is applied in the field of reinforced concrete cast-in-place frame structures of buildings, which can solve the problems of trouble, affecting installation, and the inability to adjust the height or the distance between the left and right of the steel support structure, so as to improve the prefabrication rate and improve the overall seismic performance. , the effect of reducing seismic loads and foundation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

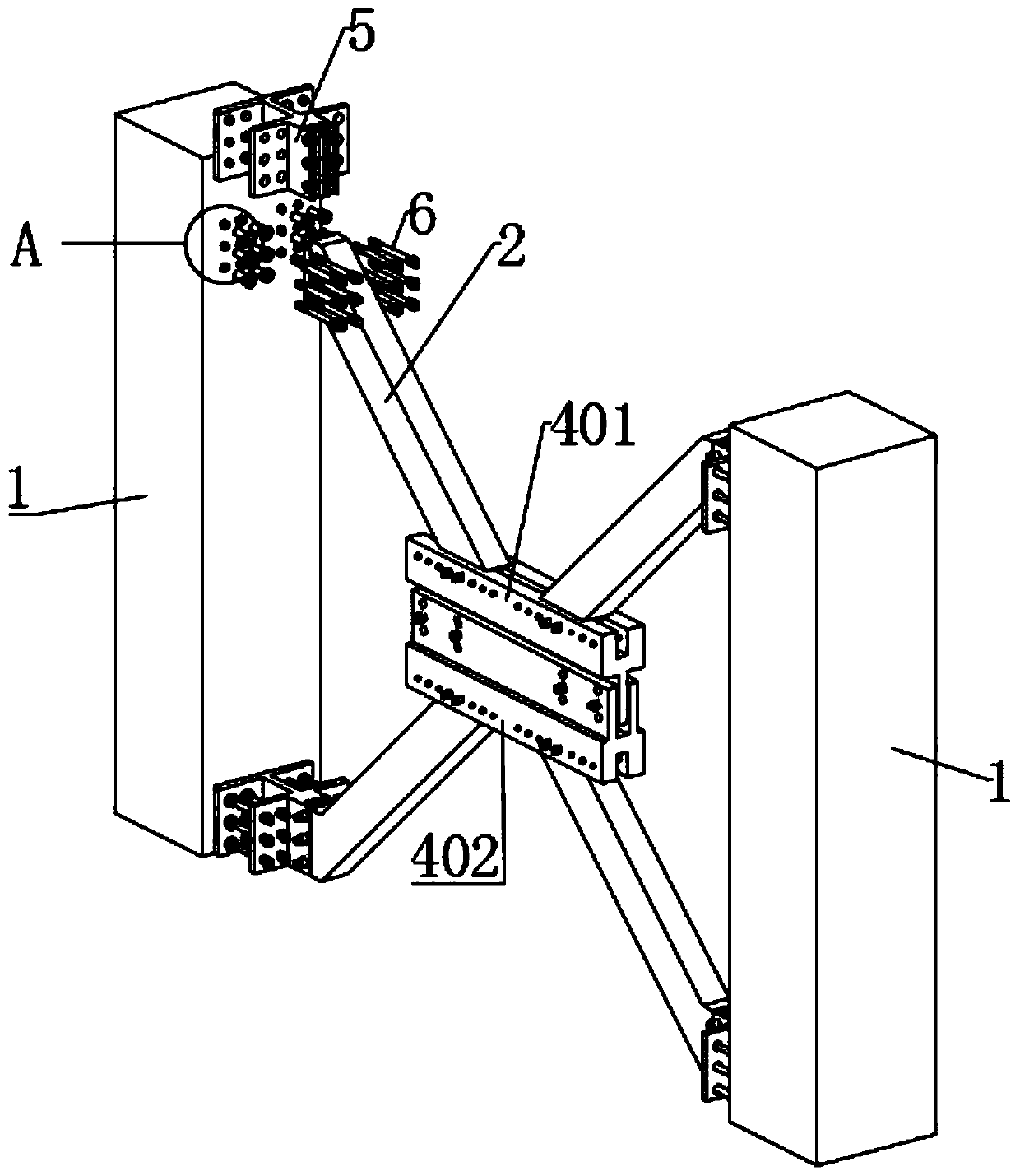

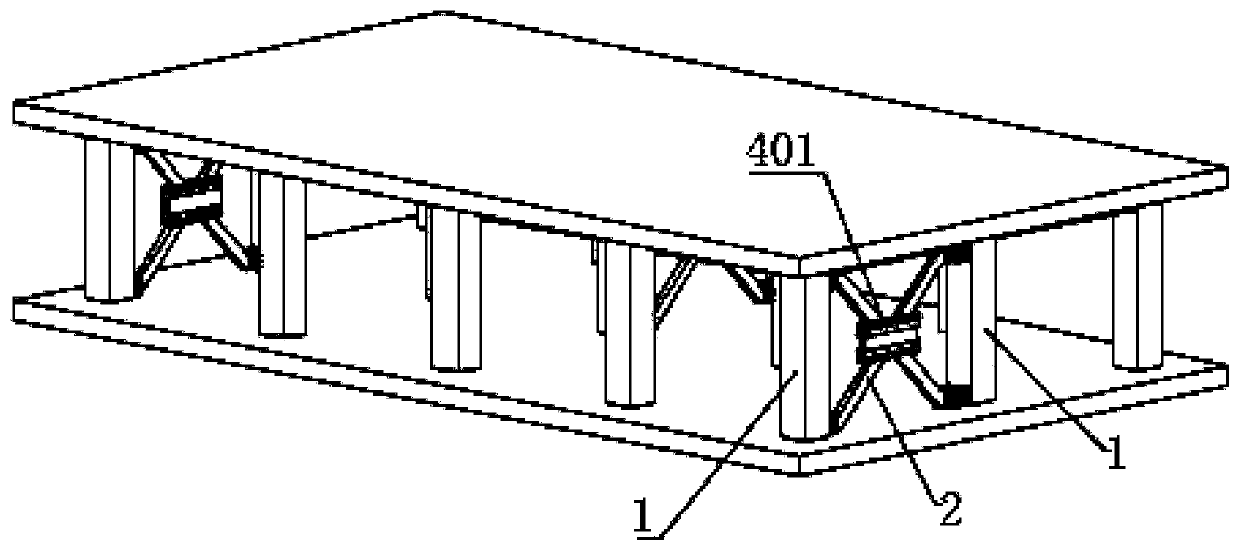

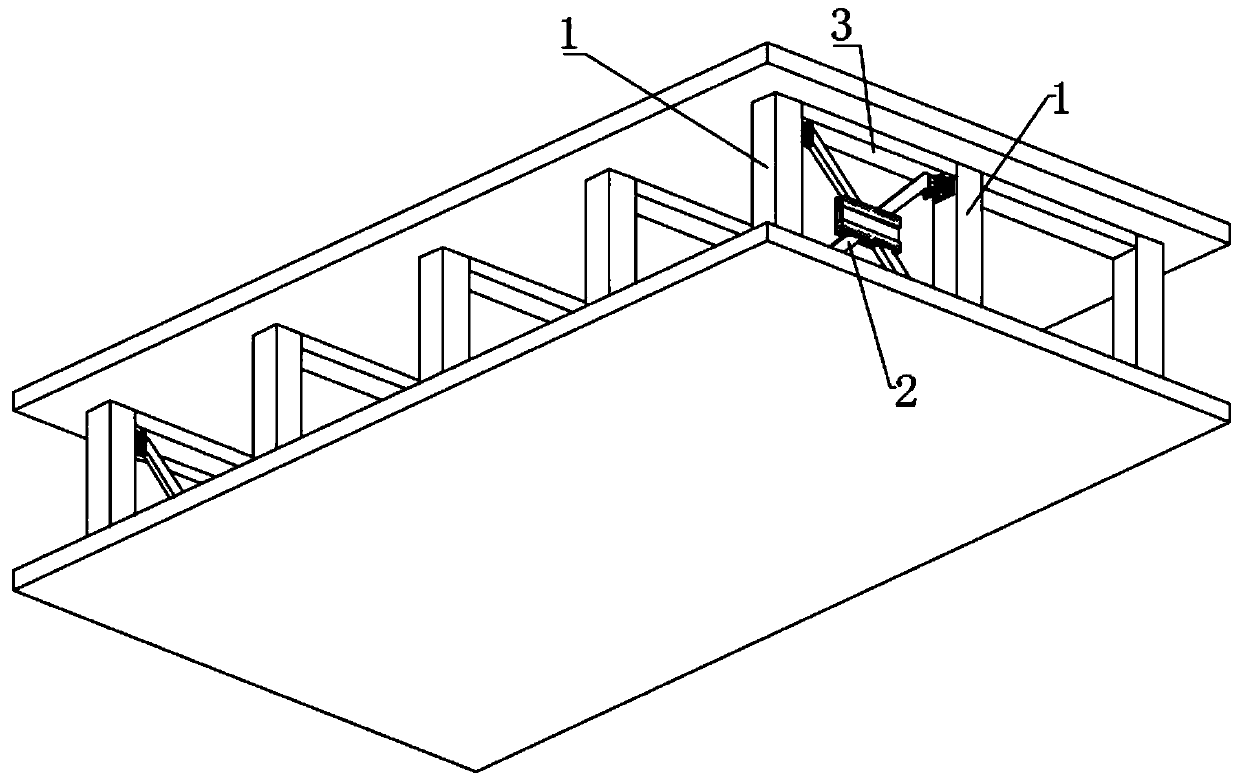

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036]The invention provides a reinforced concrete cast-in-place frame structure of a building, which includes a reinforced concrete cast-in-place column 1, a reserved hole 101, a pre-embedded threaded steel bar 102, a diagonal connecting rod 2, a horizontal sliding plate 201, a horizontal insert plate 202, and a beam 3 , upper adjustment plate 401, lower adjustment plate 402, horizontal adjustment groove 403, vertical adjustment groove 404, vertical sliding plate 405, Shi-type connecting block 5, first perforation 501, second perforation 502, slot 503, threaded rod 6. Nut 601, connecting through hole A7, connecting through hole B8, T-shaped threaded sleeve 9 and internal threaded hole 901; the upper and lower inner sides of the reinforced concrete cast-in-place column 1 are provided with twelve sets of reserved holes 101, and the pre-embedded threaded steel bars 102 connected with the internal reinforcement of the rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com