Built-in sunshade hollow glass product

A technology for shading insulating glass and glass, which is applied in the direction of shading screens, door/window protection devices, windows/doors, etc. Smooth and precise operation, improved smoothness, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

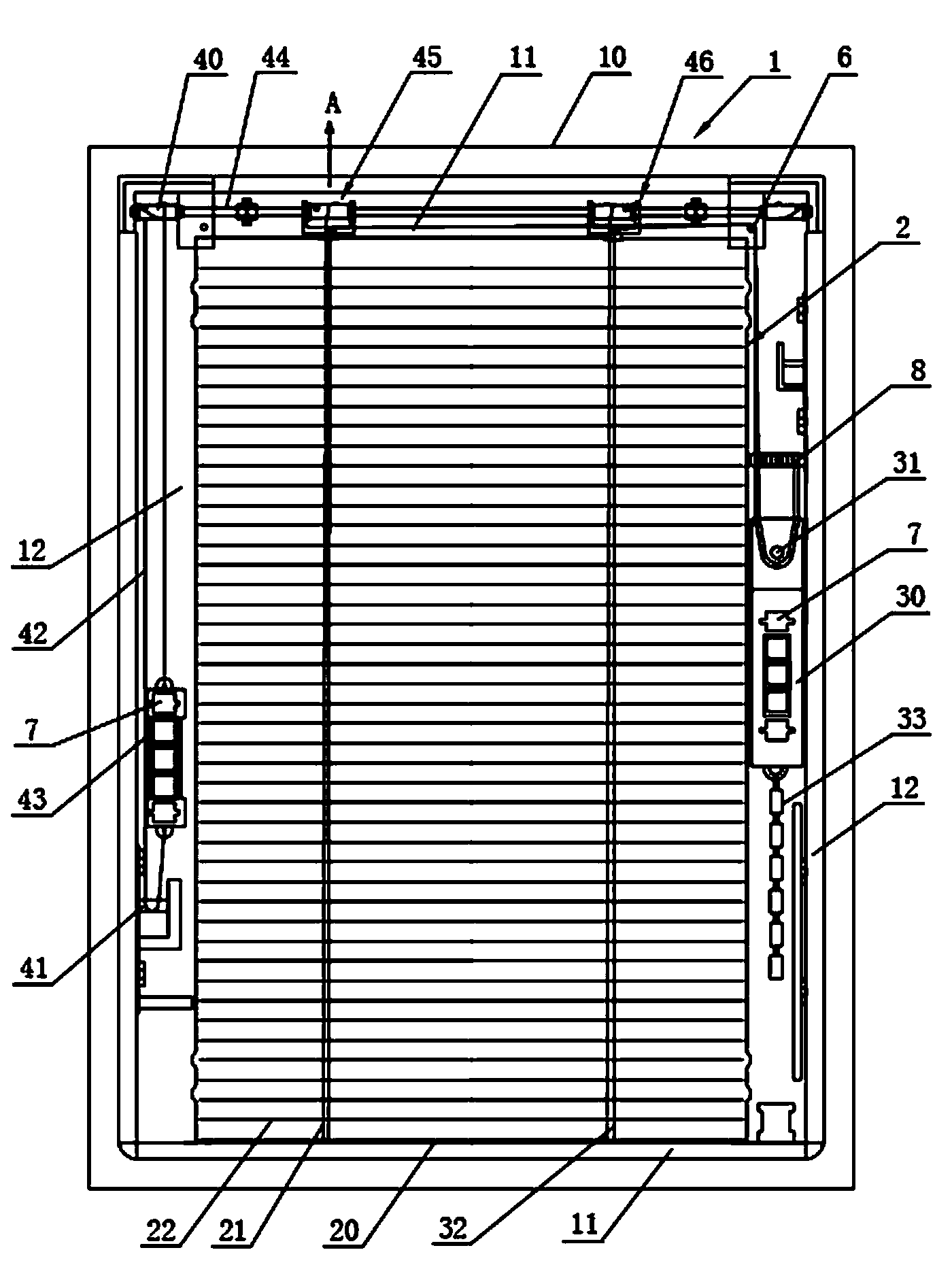

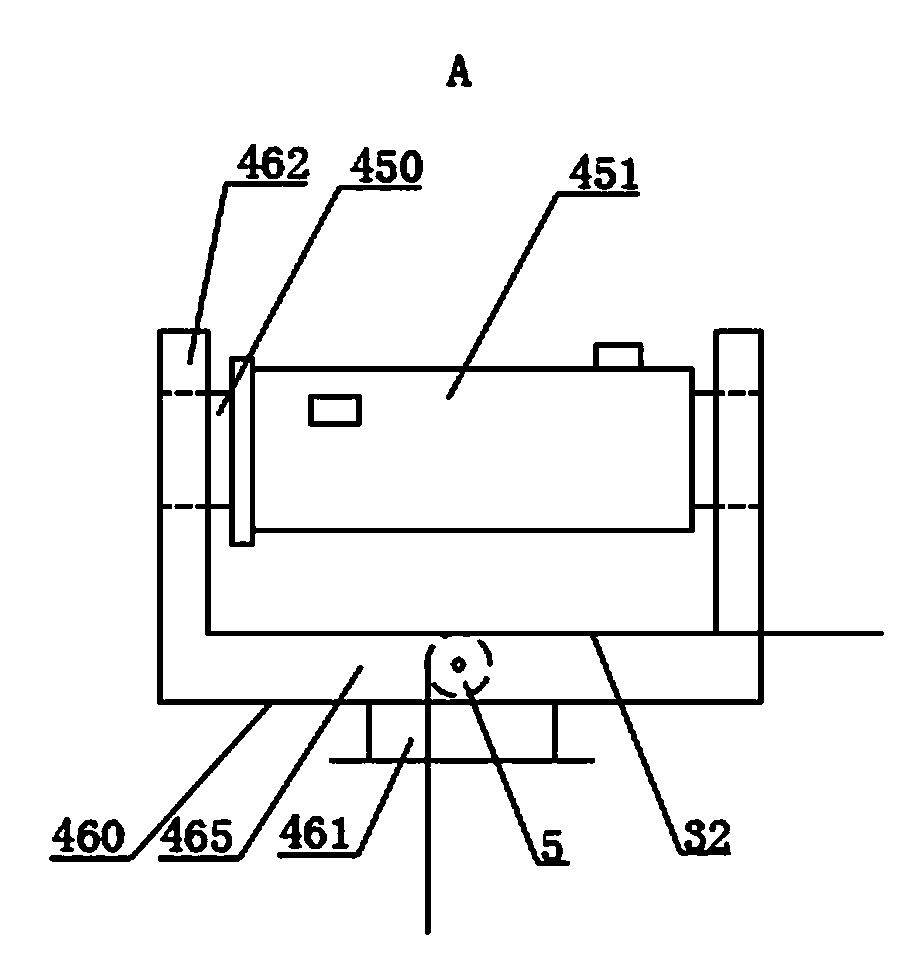

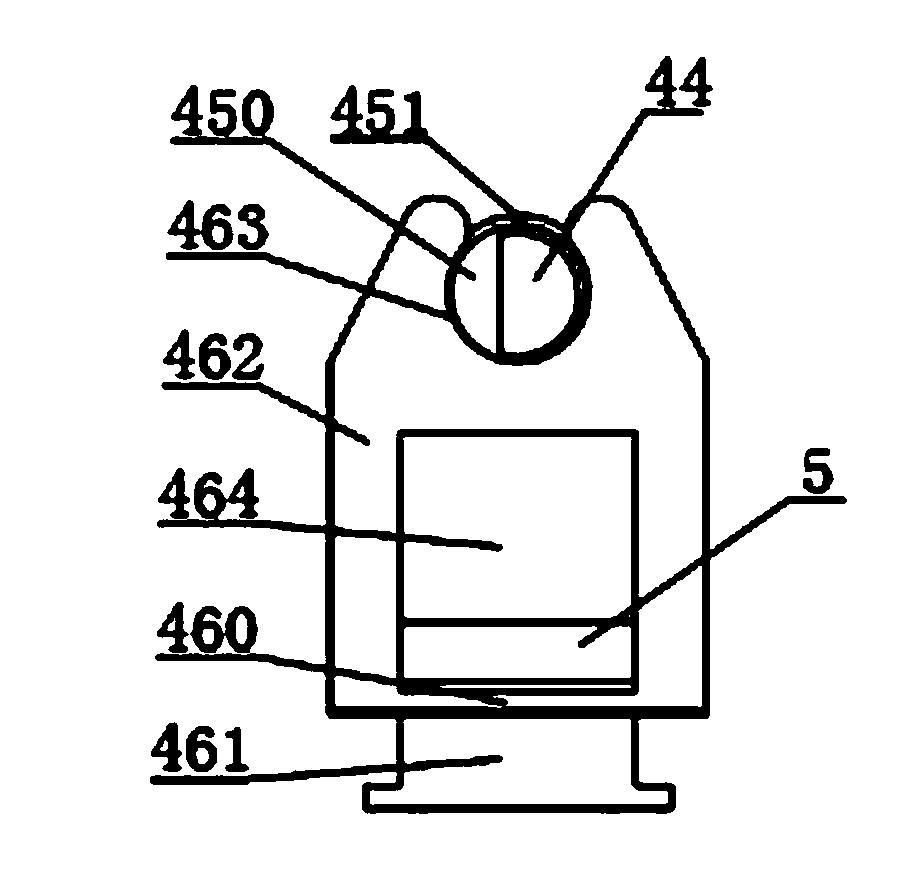

[0023] Such as Figures 1 to 4 As shown, the built-in sunshade hollow glass product according to this embodiment is specifically a hollow glass window with a built-in venetian blind, which is mainly composed of a sealed hollow glass 1, a venetian blind 2 arranged in the hollow glass 1, and a device for controlling the venetian blind 2. A blade retracting mechanism for lifting and lowering the blade 22 and a blade turning mechanism for controlling the leaf turning of the blade 22 .

[0024] Hollow glass 1 is known, and it comprises glass 10, the first frame 11 that is positioned at glass 10 upper and lower two sides and the second frame 12 that is positioned at glass 10 left and right two sides, and four frames are rectangular parallelepiped and hollow frame, and frame interior is connected. A venetian blind 2 is also known, which includes a bottom beam 20, ladder cords 21, a plurality of vanes 22, and the like. The problem to be solved by the present invention is to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com