Hollow glass with built-in blinds

A sun-shading insulating glass and hollow technology, which is applied in door/window protection devices, shading screens, windows/doors, etc., can solve the problems of excessive and fast lowering of blades, failure, damage to blades, etc., and achieve stable and stable turning operation Accurate, improve service life, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

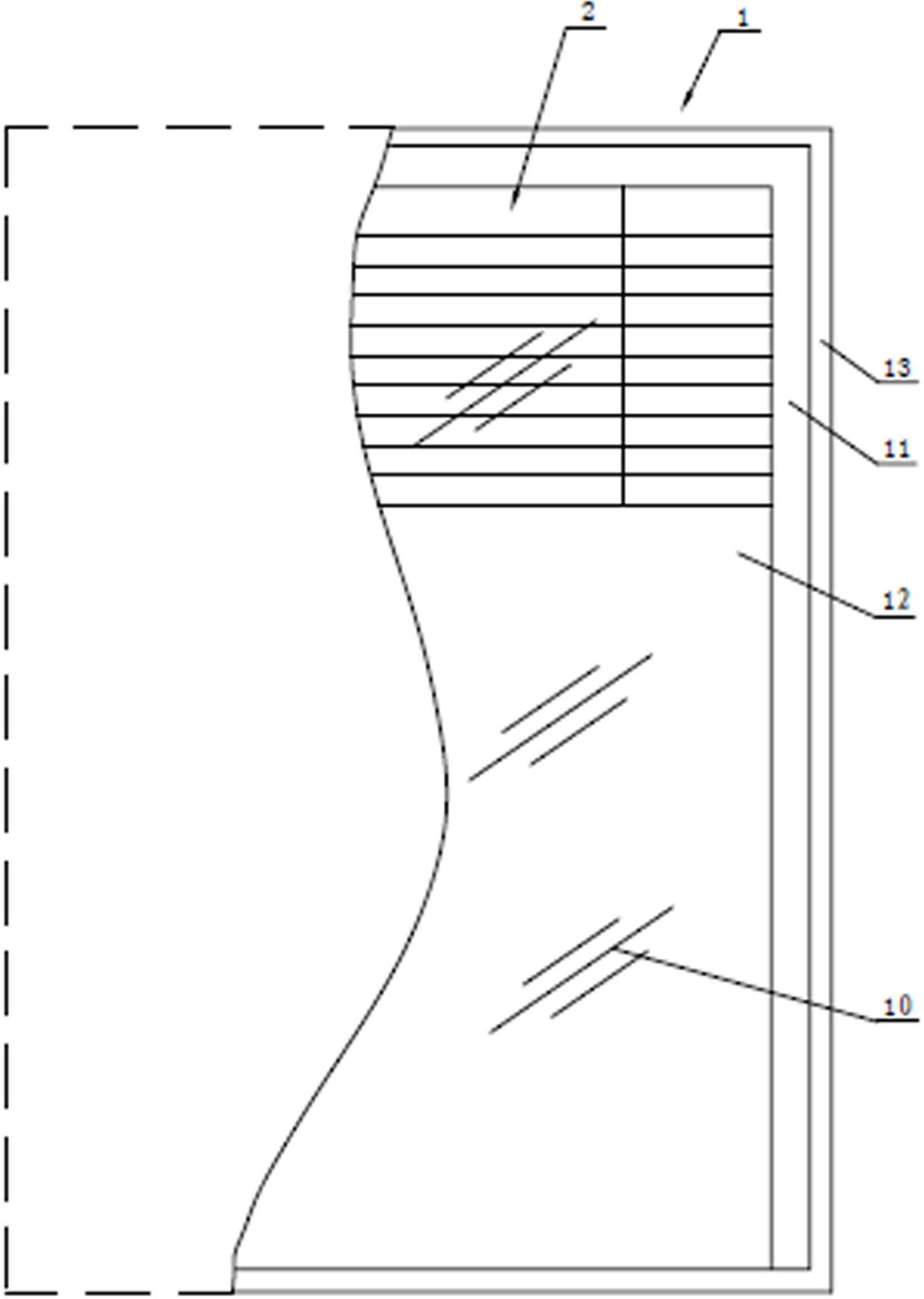

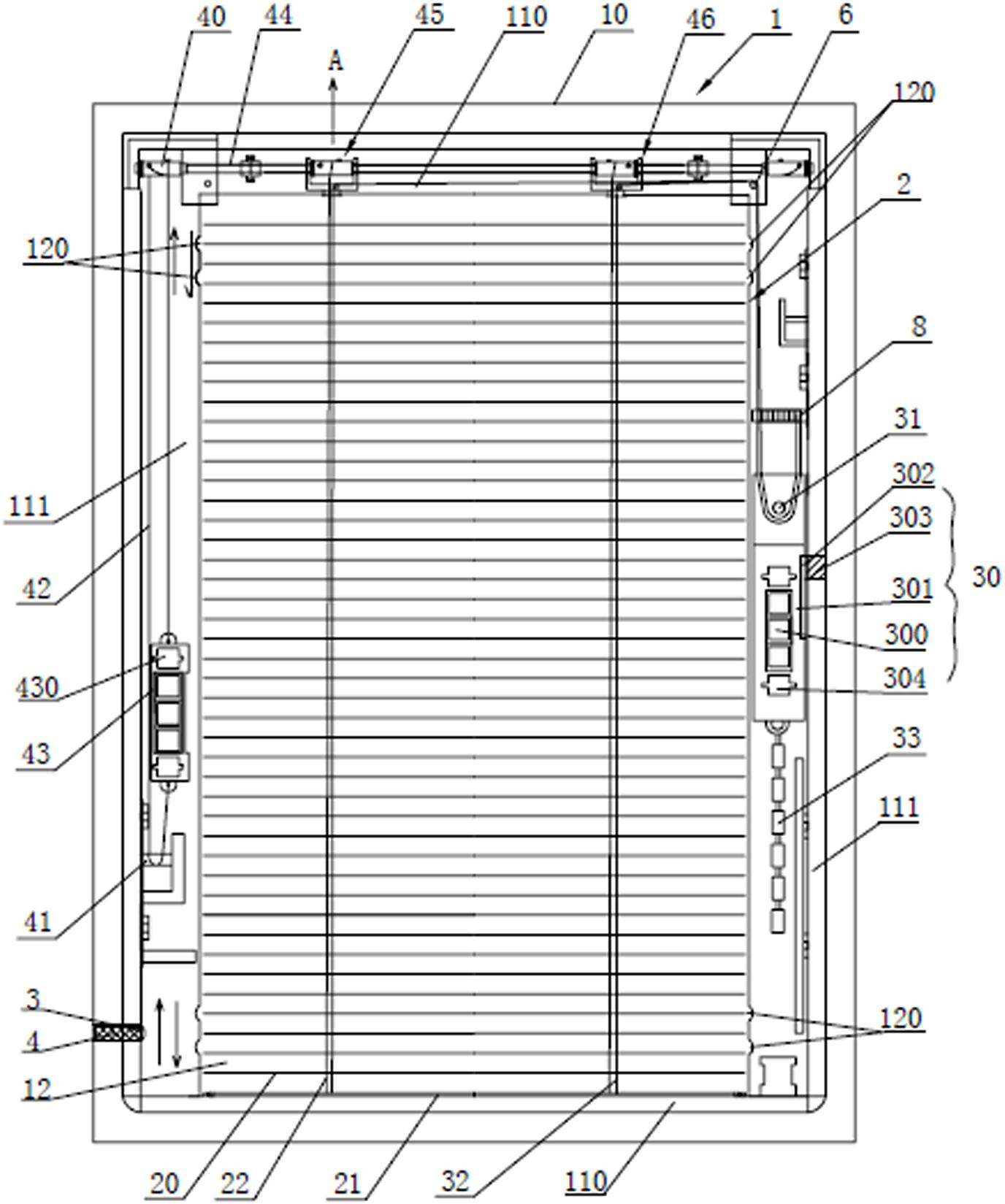

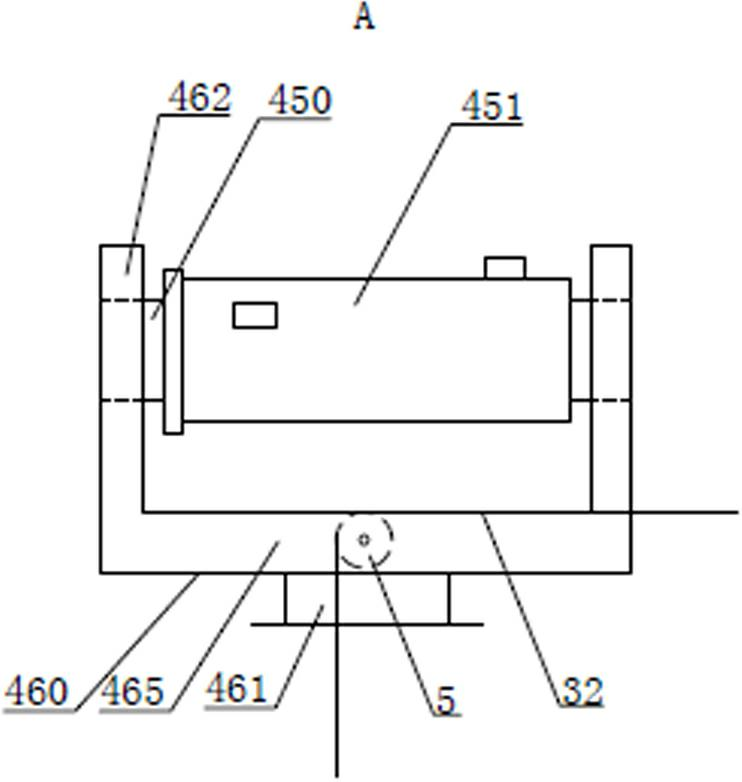

[0035] like Figures 1 to 5 As shown, the built-in sunshade hollow glass according to this embodiment is specifically a hollow glass window with a built-in venetian blind, which is mainly composed of a sealed hollow glass 1, a venetian blind 2 arranged in the hollow glass 1, and blades for controlling the venetian blind 2 The lifting and falling blade retracting mechanism of 20 and the blade turning mechanism for controlling blade 20 page turning.

[0036] Insulating glass 1 is known, and it comprises two glass original sheets 10 parallel to each other, a metal hollow frame 11 sandwiched between the two glass original sheets 10, surrounded by the two glass original sheets 10 and the metal hollow frame 11. The hollow part 12 and the sealant 13 are formed. The metal hollow frame 11 includes a first frame 1100 located on the upper and lower sides and a second frame 111 located on the left and right sides. The metal hollow frame 11 is made of aluminum alloy.

[0037] A venetian ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com