Power generation plant with co2 capture and compression

A power generation equipment, CO2 technology, applied in the direction of mechanical equipment, machines/engines, chemical instruments and methods, etc., can solve the problems of power and efficiency loss of generators and motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

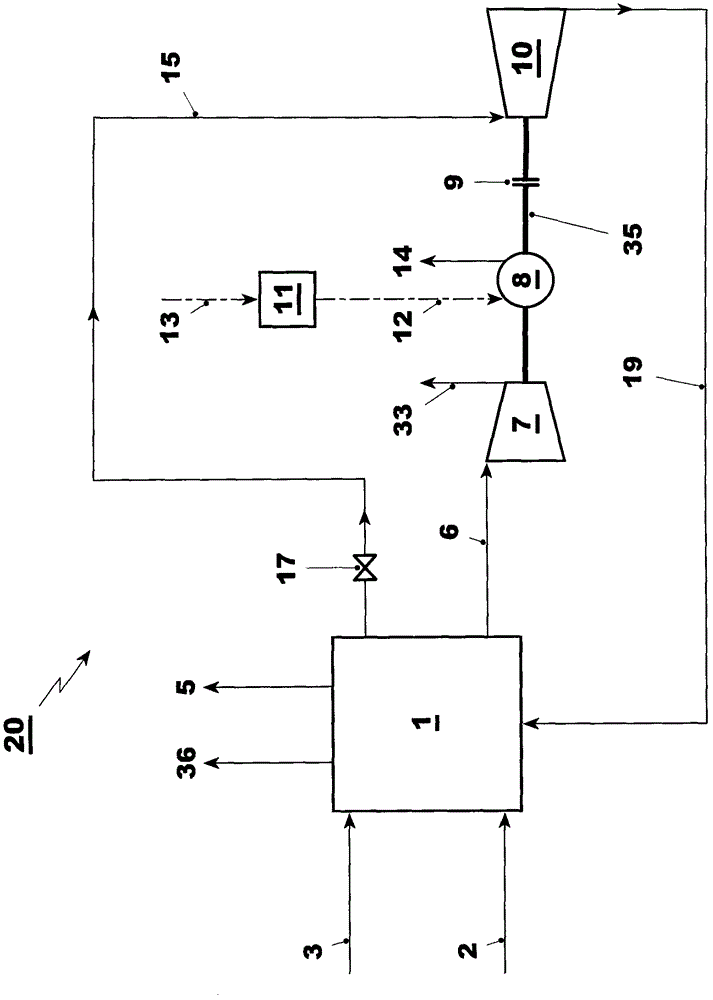

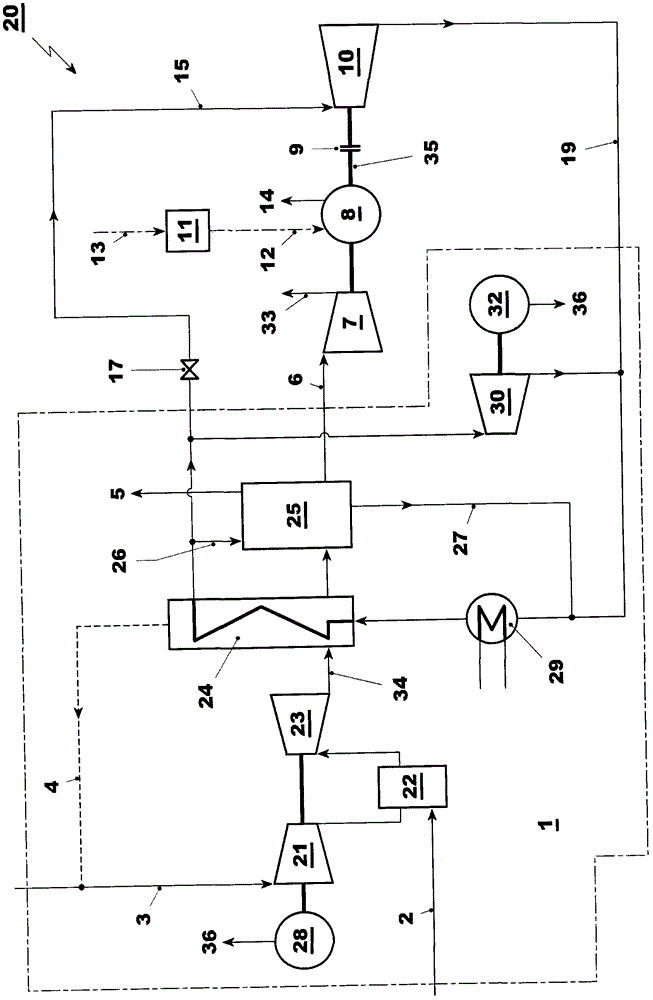

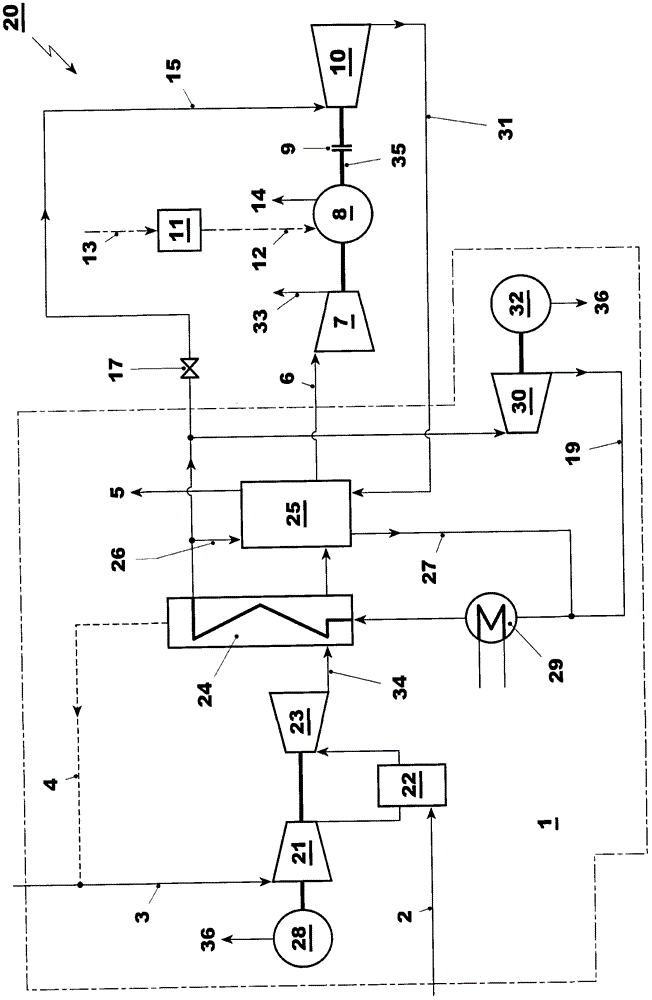

[0076] The power generation plant for carrying out the proposed method comprises a power generation unit 1 comprising CO 2 capture system, CO 2 Compressor 7 , generator 8 , overrunning clutch 9 and steam turbine 10 .

[0077] exist figure 1 A typical arrangement is shown in . The power generation unit 1 is supplied with fuel 2 and ambient air 3 . The power generation unit 1 comprises a conventional fossil fuel fired power plant with at least one water-steam cycle. It may, for example, be a combined cycle power plant, a conventional coal fired steam power plant or an IGCC. The power generation unit includes CO 2 Capture system that removes CO generated during the power generation process 2 . Typically, during backend capture, the CO 2 It is removed from the flue gas, but it can also be removed during the power generation process, as in the case of IGCC.

[0078] In addition to the power delivered to the grid via the mains connection 36, the power generation unit produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com