Concentrate sampling machine

A sampling machine, concentrate technology, applied in sampling devices and other directions, can solve problems such as high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

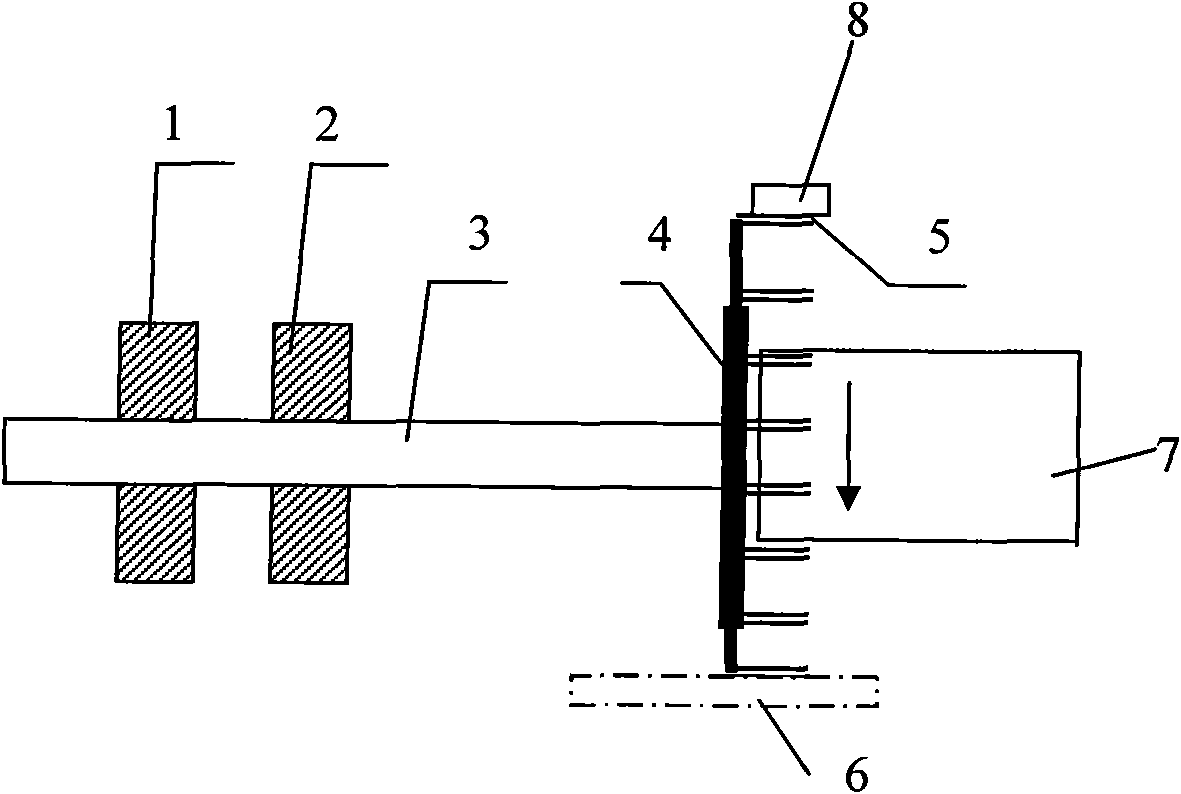

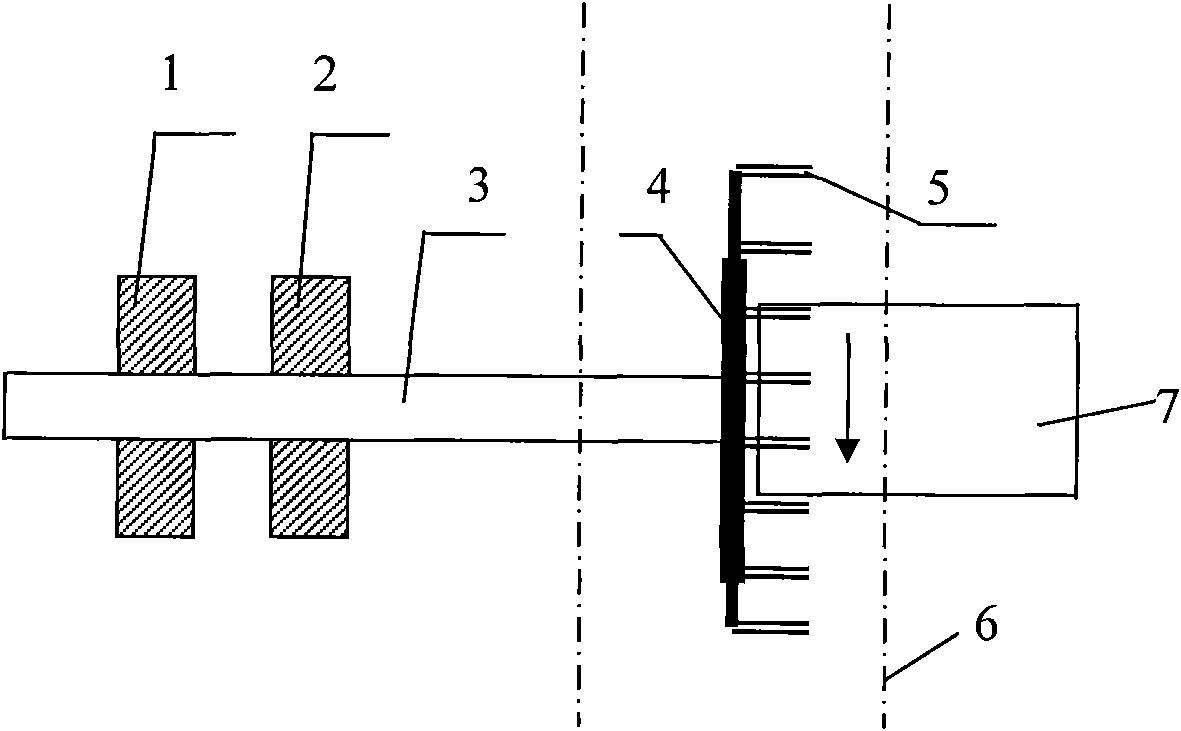

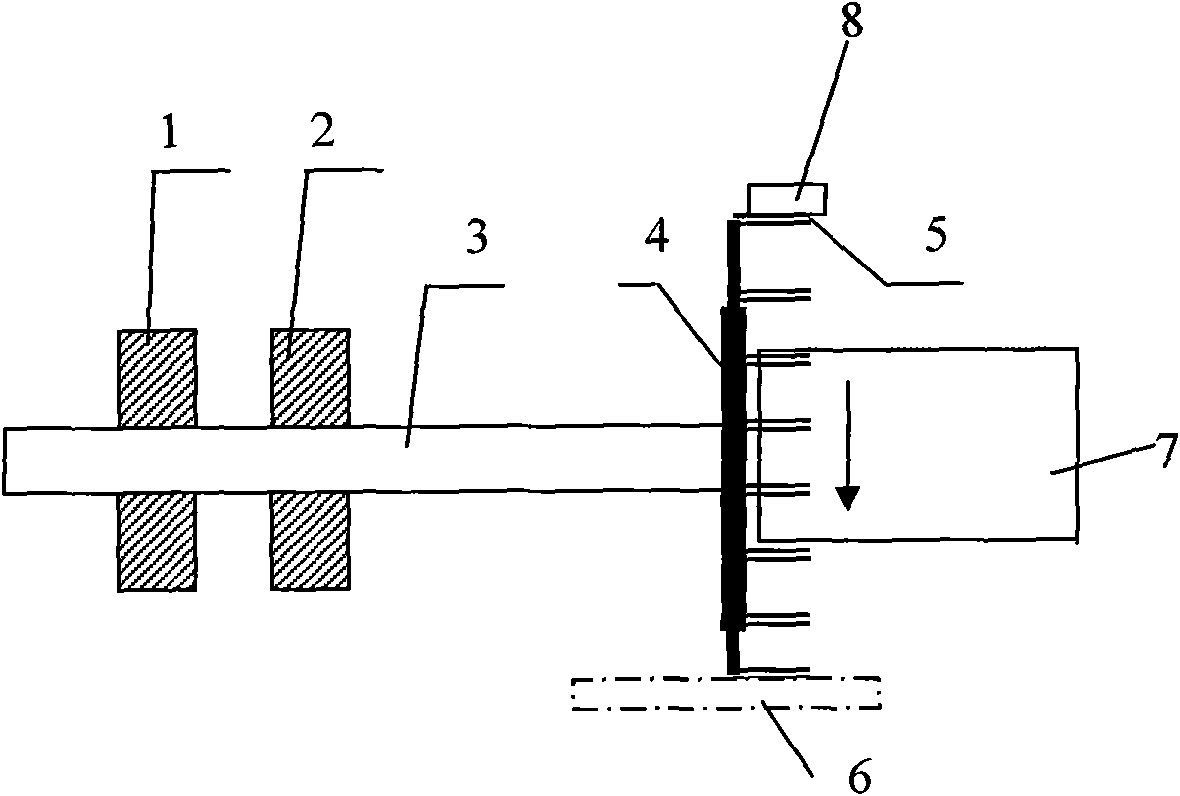

[0010] In the figure, in the concentrate sampling machine, multiple sampling spoon heads 5 are evenly distributed on the circumference of the turntable 4, the turntable 4 is connected with a coaxial rotating shaft 3, and the rotating shaft 3 is connected to a bracket (not shown) through two bearing seats 1, 2 )on. The sampling spoon head 5 is a round rod parallel to the rotating shaft, and the round rod is perpendicular to the movement direction of the belt 6. The belt 6 is located below and cuts the circumference of the sampling spoon head 5; the scraper 8 is located above and tangent to the circumference of the sampling spoon head, and a receiving hopper 7 is arranged below the scraper 8.

[0011] Because the sampling spoon head presses the belt, when the belt moves forward, the friction force and the impulse generated by the moving concentrate push the sampling spoon head to continuously rotate around the axis of the rotating shaft. During the rotation of the sampling spoon h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com