Sectional cooling control method for emulsion of working roller of single-frame rolling mill

A technology of segmented cooling and control method, applied in the direction of roll, metal rolling, profile control, etc., can solve the problems of lag in the mechanism of emulsion spray cooling and inability to accurately control, meet real-time requirements, and improve shape quality. , The effect of eliminating high-order shape deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

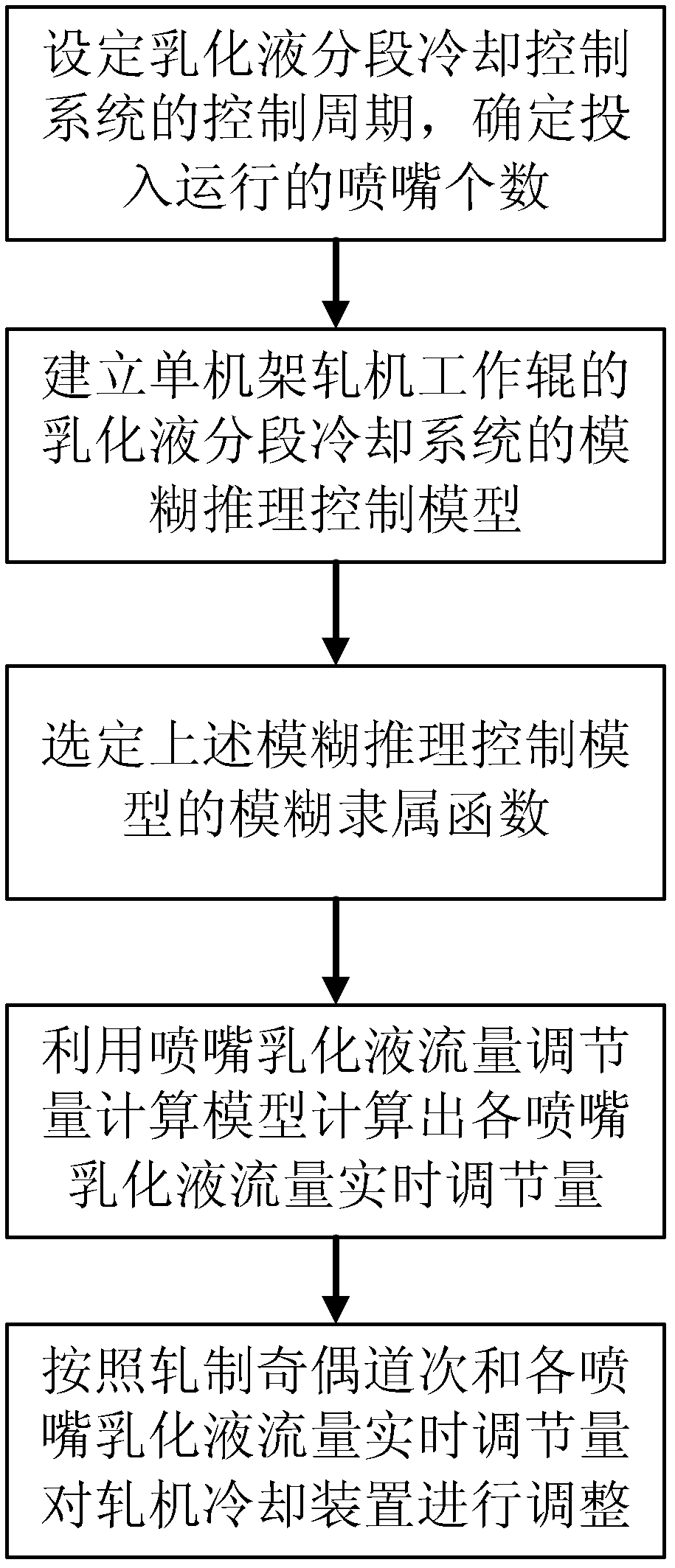

[0055] The emulsion cooling control method for the work roll of a single-stand rolling mill provided by the present invention is characterized in that the relationship between the plate shape deviation, the past emulsion injection flow adjustment amount and the current emulsion injection flow adjustment amount is established by the fuzzy modeling method. Quantitative relationship, the calculation model of nozzle emulsion flow adjustment based on fuzzy model is designed, and the flow control valve of segmental cooling nozzle is adjusted online, so as to realize the high-precision emulsion cooling control of single-stand rolling mill work rolls.

[0056] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

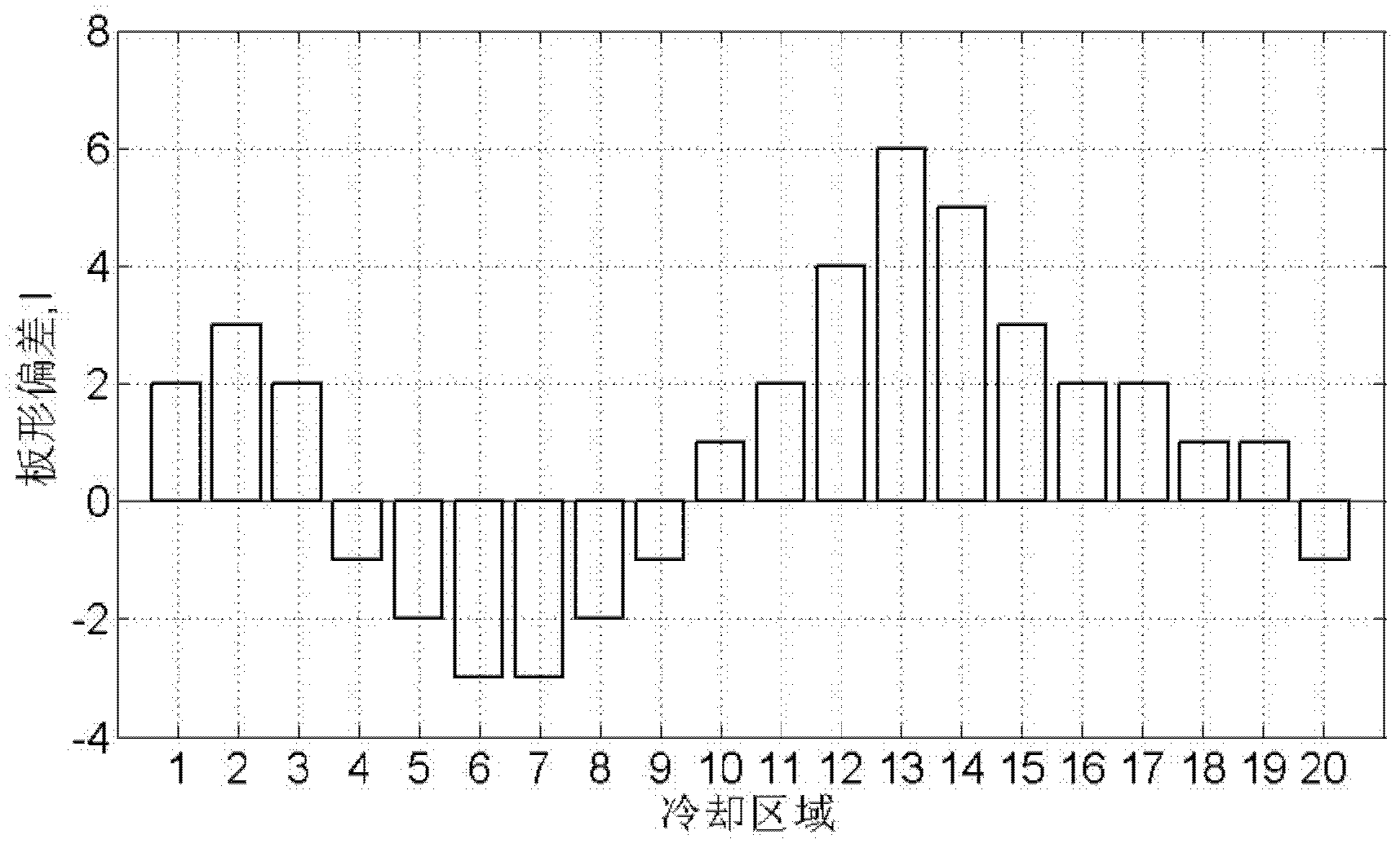

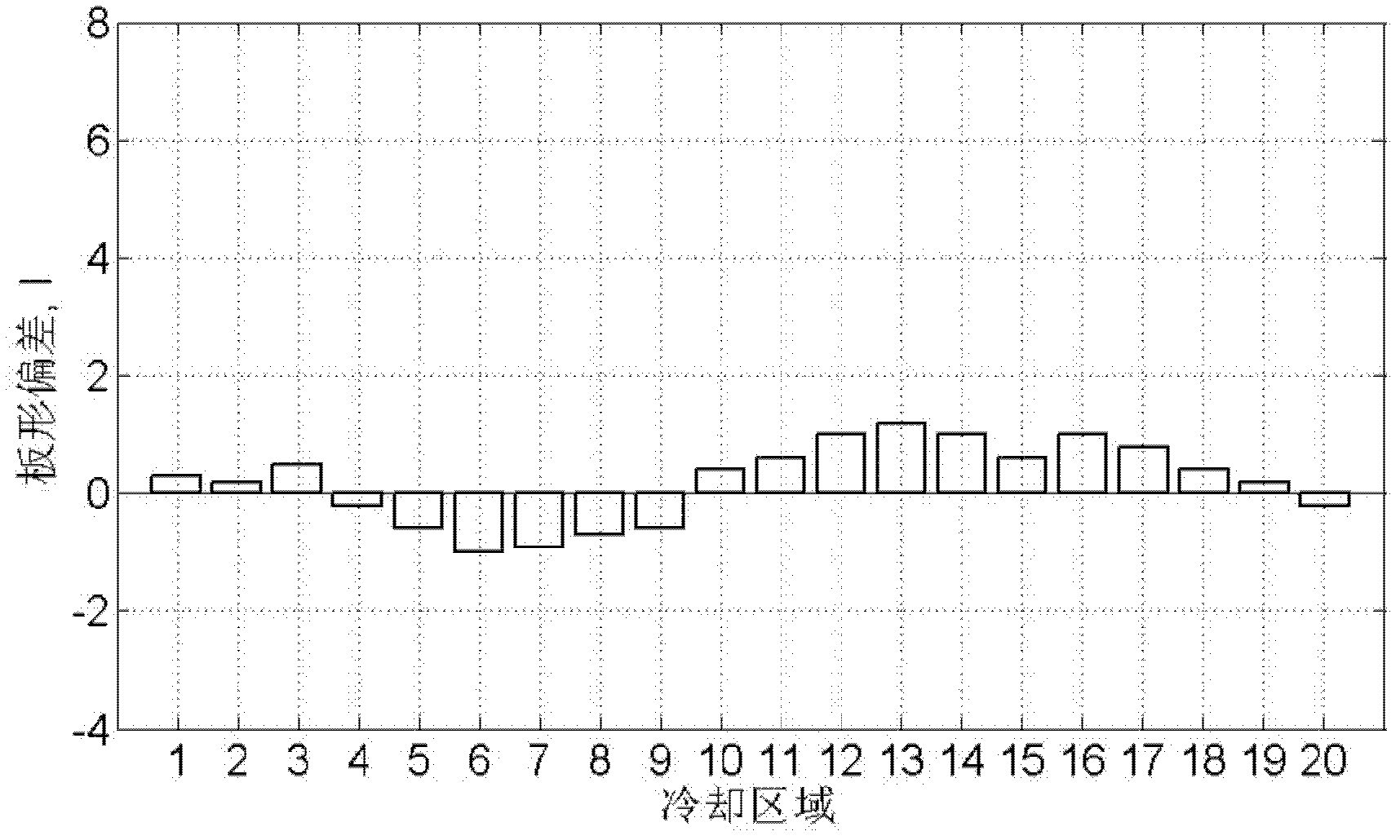

[0057] Strip steel production for a single-stand reversing cold rolling mill based on the invention. The invention has been successfully applied on a single stand six-hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com