Clamping location pneumatic gripper

A pneumatic gripper, clamping and positioning technology, applied in the field of manipulators, can solve the problems of inaccurate positioning of manipulators, and achieve the effects of simple structure, precise positioning and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

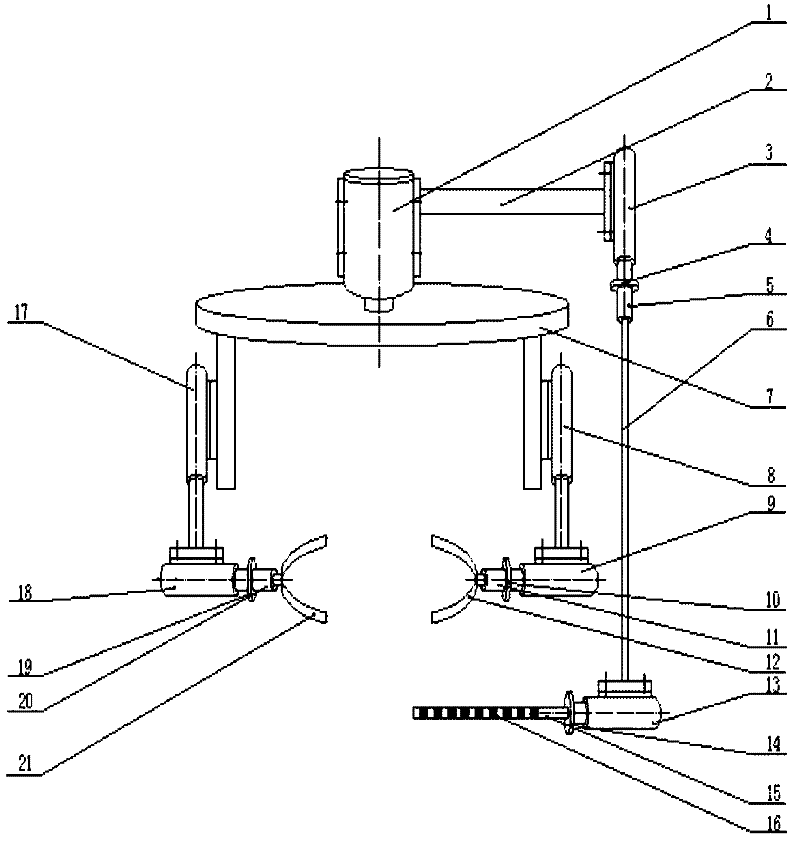

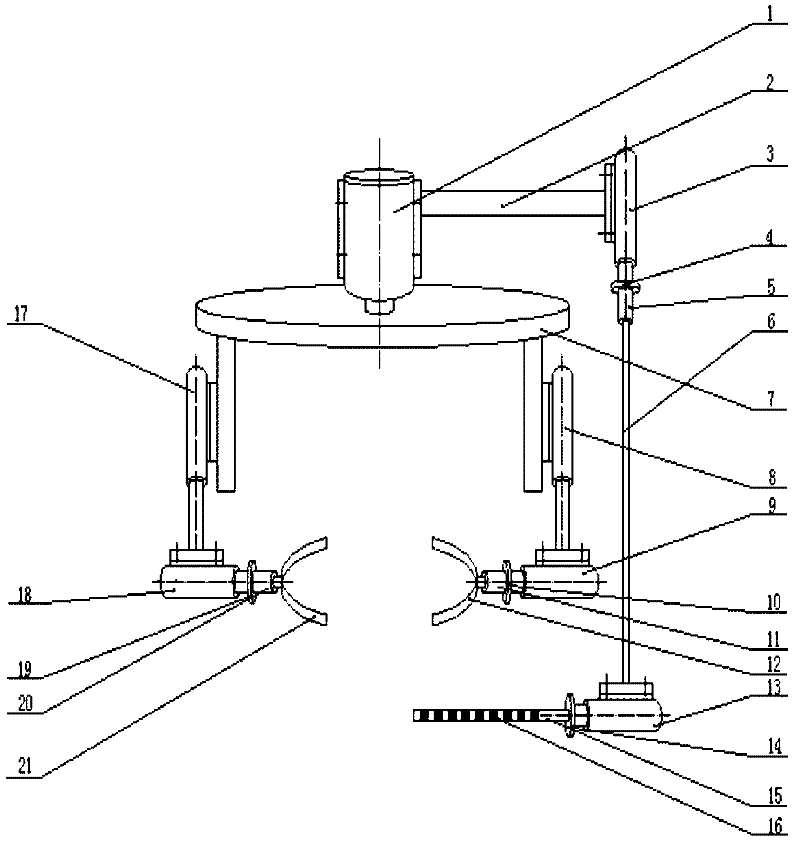

[0016] The pneumatic gripper for clamping and positioning, as shown in the figure, includes motor I1, fixed rod I2, cylinder I3, fixed baffle I4, motor II5, fixed rod II6, rotating plate 7, cylinder II8, cylinder III9, fixed baffle II10 , motor III11, gripper I12, cylinder IV13, fixed baffle III14, fixed rod III15, pressure sensor 16, cylinder V17, cylinder VI18, fixed baffle IV19, motor IV20, gripper II21, the housing of the motor I1 and cylinder I3 Connection; the shaft of the motor I1 is connected to the rotating plate 7, the shaft of the motor II5 is connected to the fixed rod II6, the motor III11 is connected to the claw I12, the motor IV20 is connected to the claw II21 respectively, and the pressure sensor 16 is connected to the fixed rod III15, The rod of the cylinder I3 is connected to the fixed baffle I4, the rod of the cylinder III9 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com