Pick shoe forging process

A technology of tooth shoes and picks, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of long forming process of pick and tooth shoes, low product qualification rate, and high material consumption, etc. Achieve the effects of reducing the unit extrusion force of the mold, high forming precision, and reducing metal flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

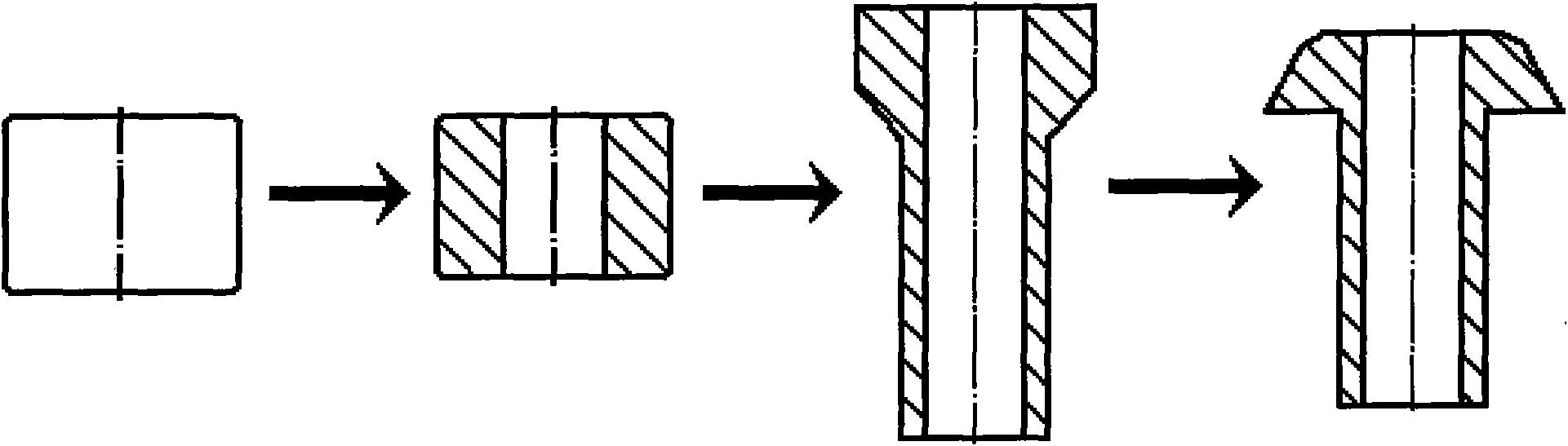

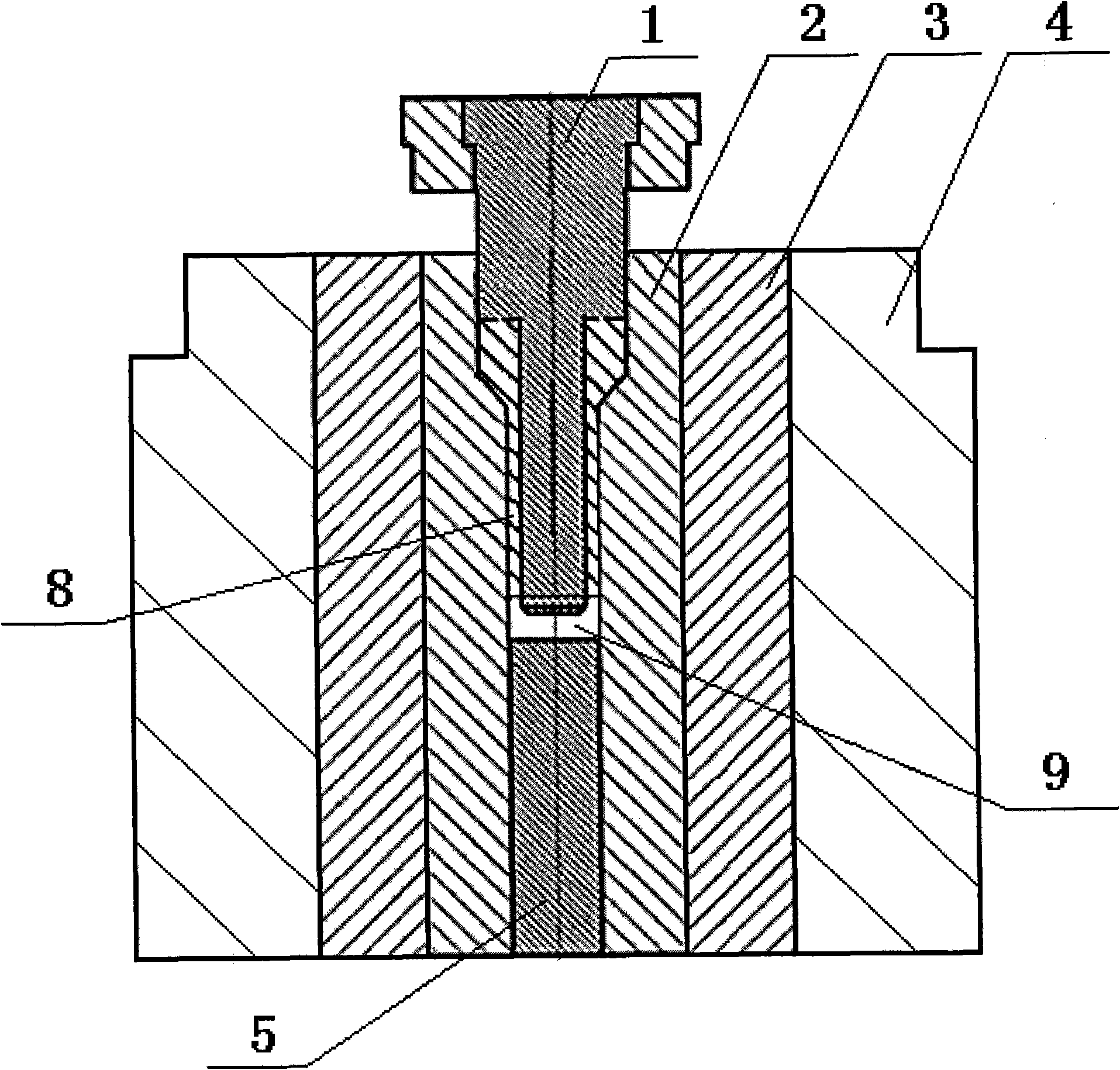

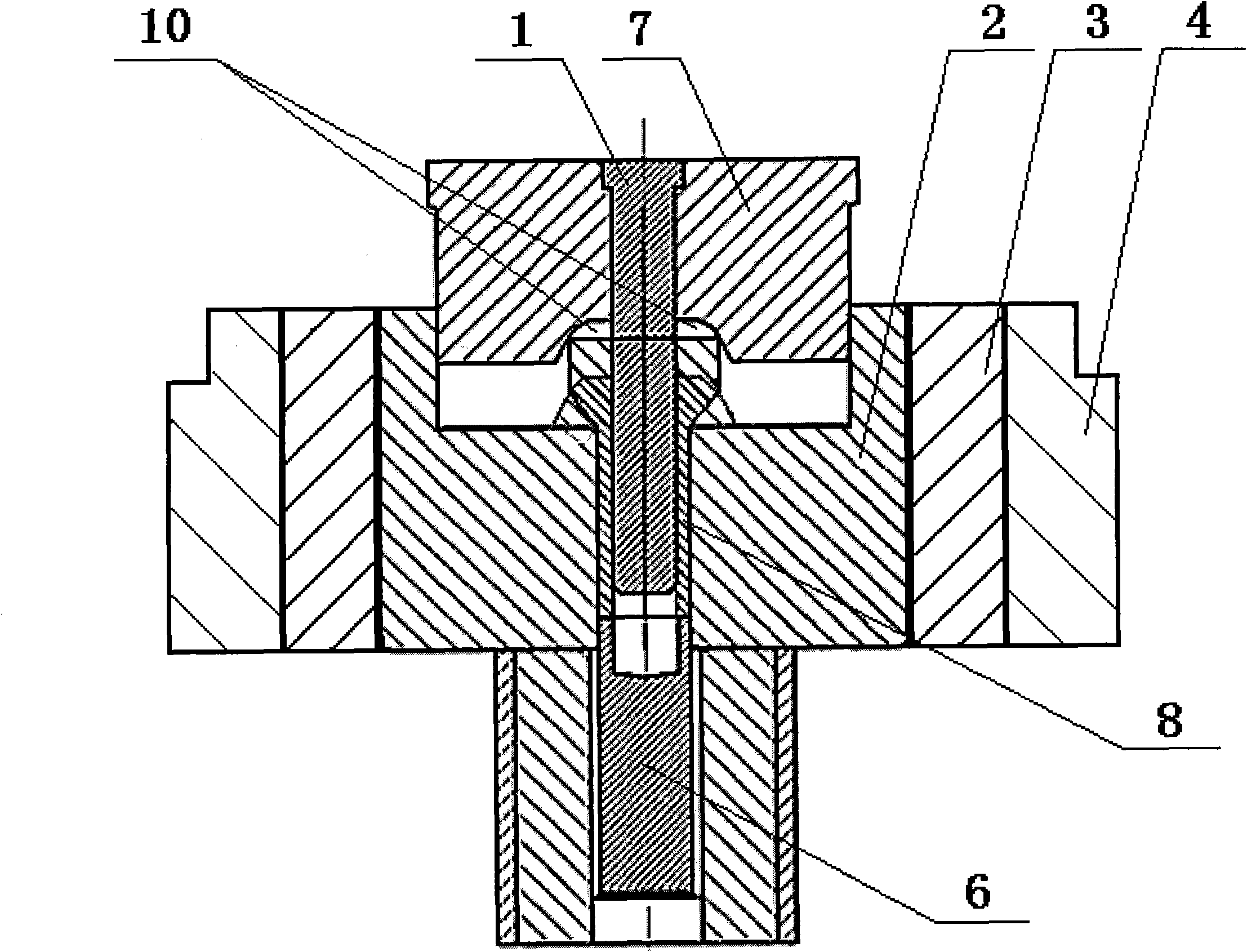

[0026] see figure 1 , figure 2 with image 3 A forging process for a pick tooth shoe, comprising the following steps:

[0027] ①Blanking, intercepting bar;

[0028] ② Blank making, peeling the outer circle of the car, and taking the length;

[0029] ③Shot blasting coating, graphite coating to prevent oxidation and decarburization after shot blasting;

[0030] ④ Upsetting punching, heating the bar to a temperature of 850°C, first upsetting in the upsetting die, and then punching in the die to form a hollow cylindrical blank;

[0031] ⑤ shot blasting coating, graphite coating anti-oxidation and anti-decarburization after shot blasting;

[0032] ⑥Heating and forward extrusion, the billet is heated to a temperature of 850°C, and the hollow cylindrical billet is put into the forward extrusion die for forward extrusion to form two hollow cylinders of different sizes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com