Air sealing member capable of opening air valve naturally and manufacturing method of air sealing member

A technology of air sealing body and manufacturing method, which is applied in the direction of preventing mechanical damage, container, transportation and packaging, etc., and can solve the problem that the air sealing body does not have the function of automatically opening the air inlet, cannot open the air passage inlet, and cannot multiple The air column is inflated at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

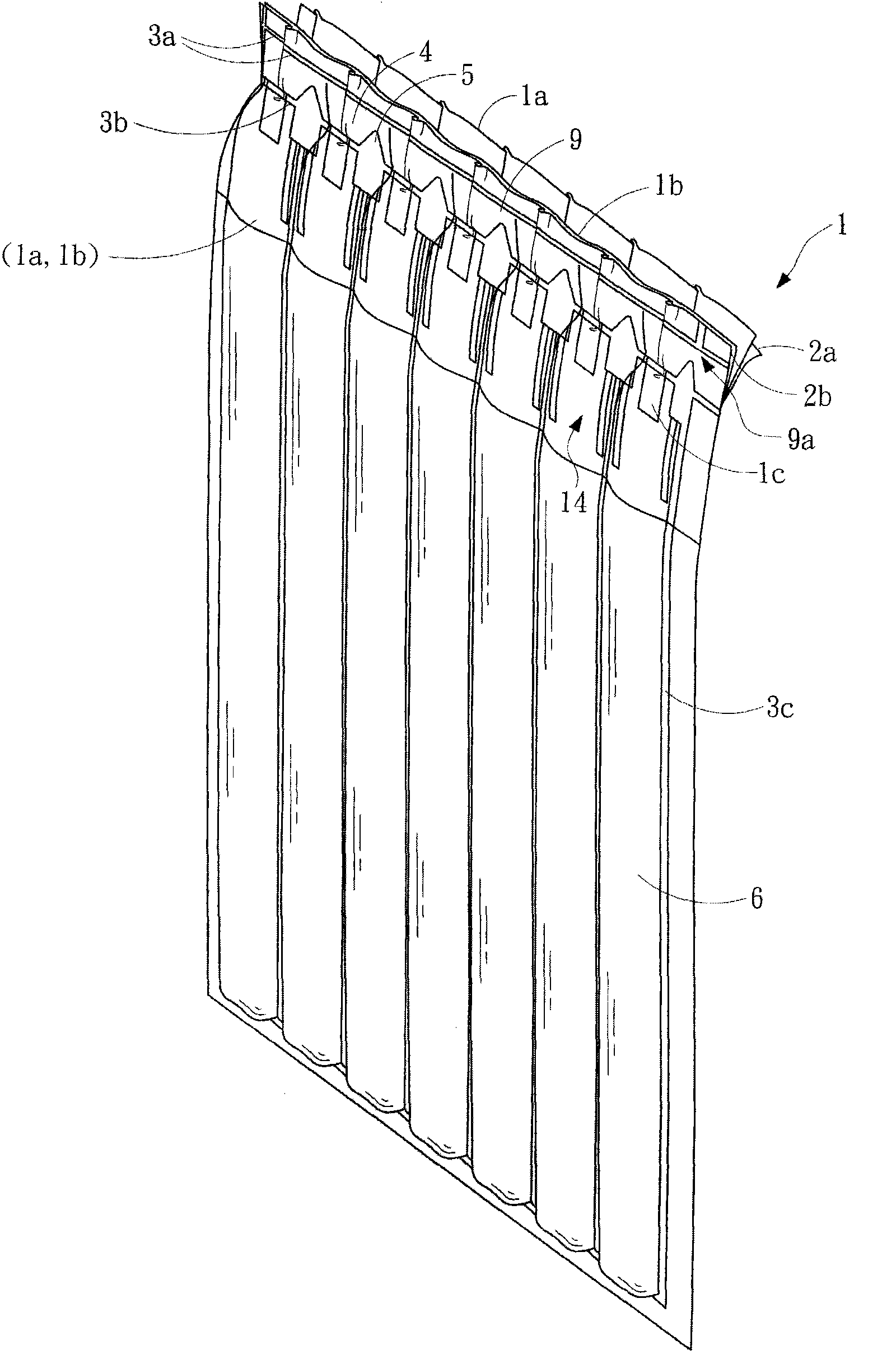

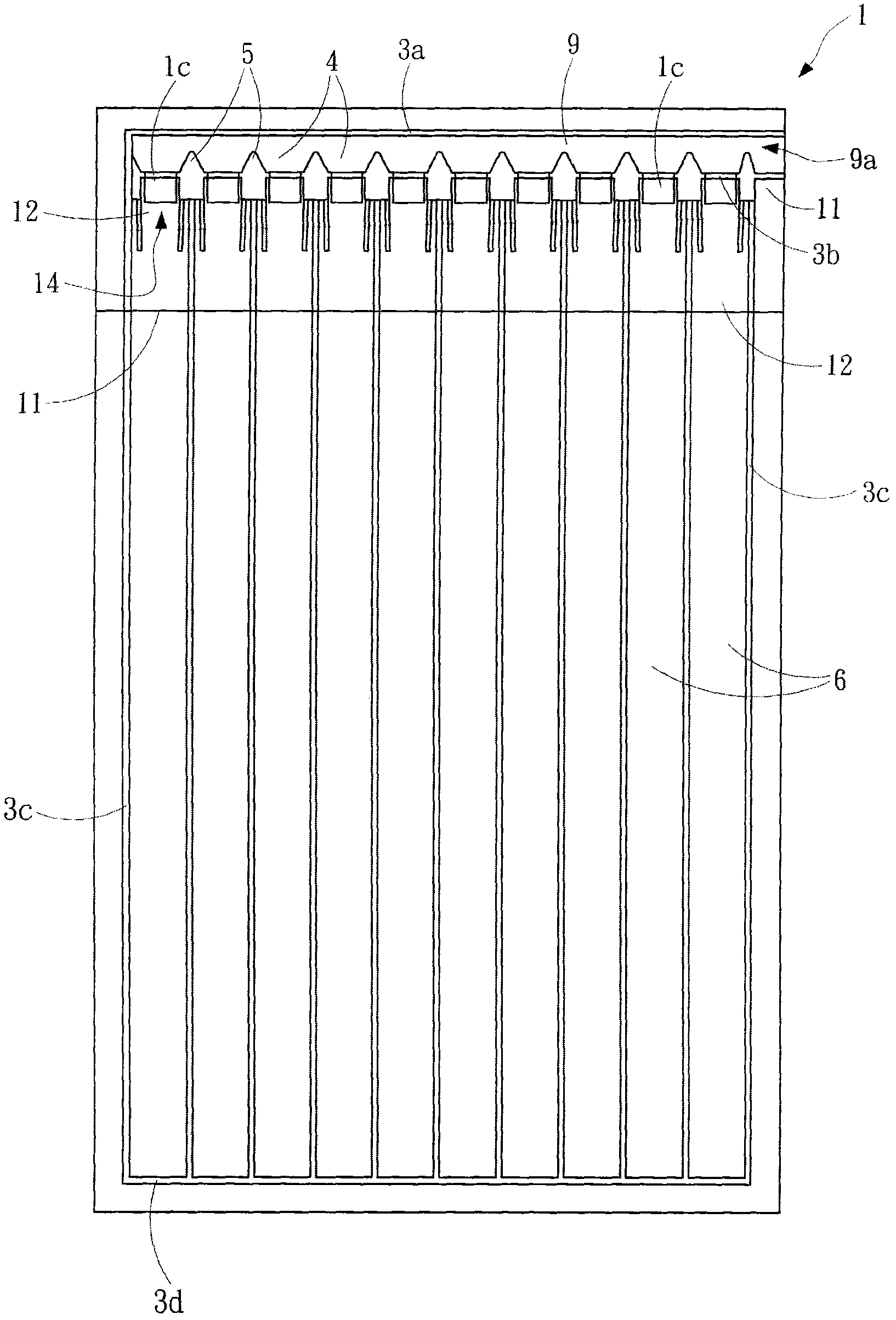

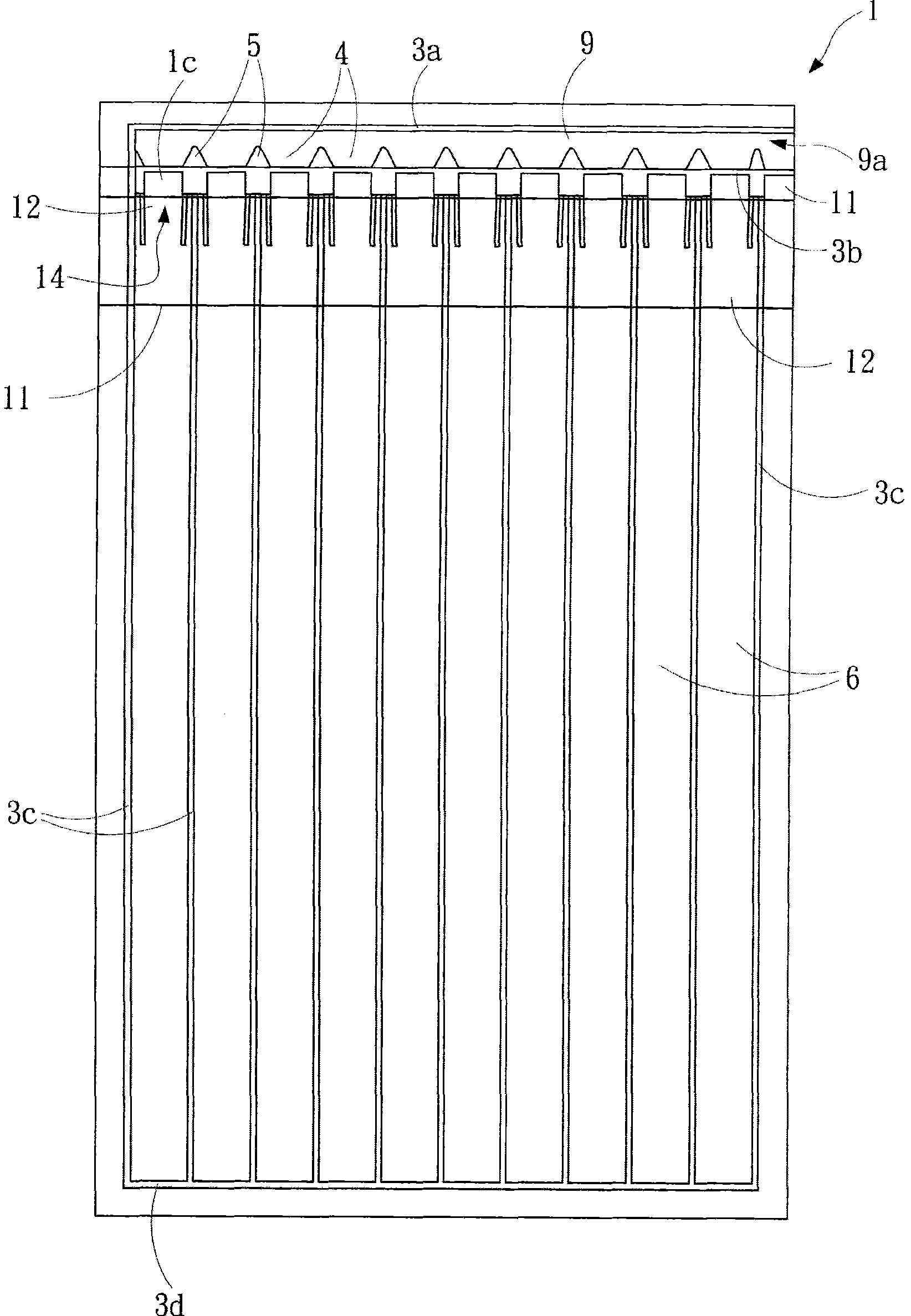

[0042] see figure 1 , Figure 2A , Figure 2B , image 3 and Figure 4 As shown, it is used to illustrate the first embodiment of the air sealing body of the natural open air valve of the present invention.

[0043] The air sealing body 1 of the present invention with a naturally open air valve includes: two outer films 2a and 2b, two inner films 1a and 1b, a heat-resistant material 1c, an inflatable channel 9, a plurality of air columns 6, and a plurality of heat-sealing areas Block 5.

[0044] Wherein, two outer membranes 2a and 2b are stacked up and down.

[0045] The two inner membranes 1a and 1b are interposed between the two outer membranes 2a and 2b, and placed slightly lower on the inner top of the two outer membranes 2a and 2b. The wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com