Green grain storage granary

A granary and green technology, applied in the field of granaries, can solve the problems of high construction/renovation cost and use cost, low input-to-output ratio, and impact on grain quality, and achieve shortened inflation time, reduced construction costs, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

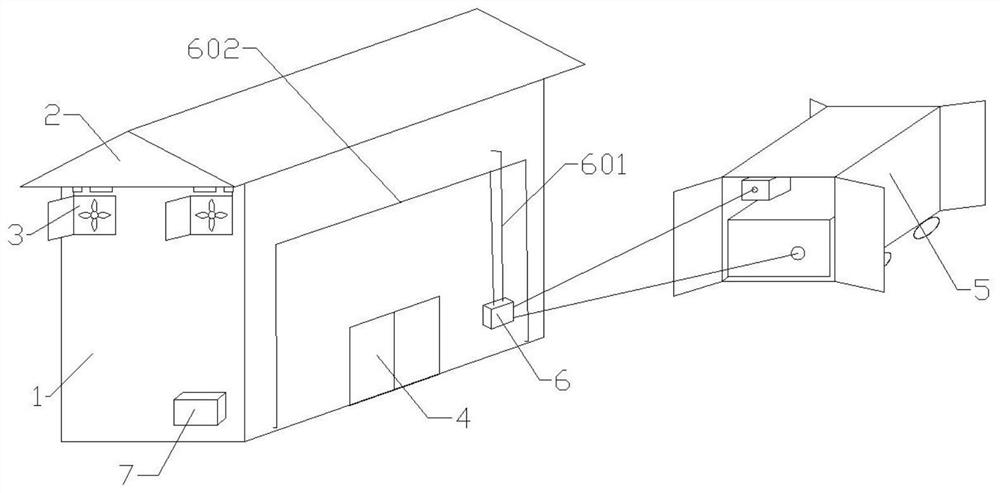

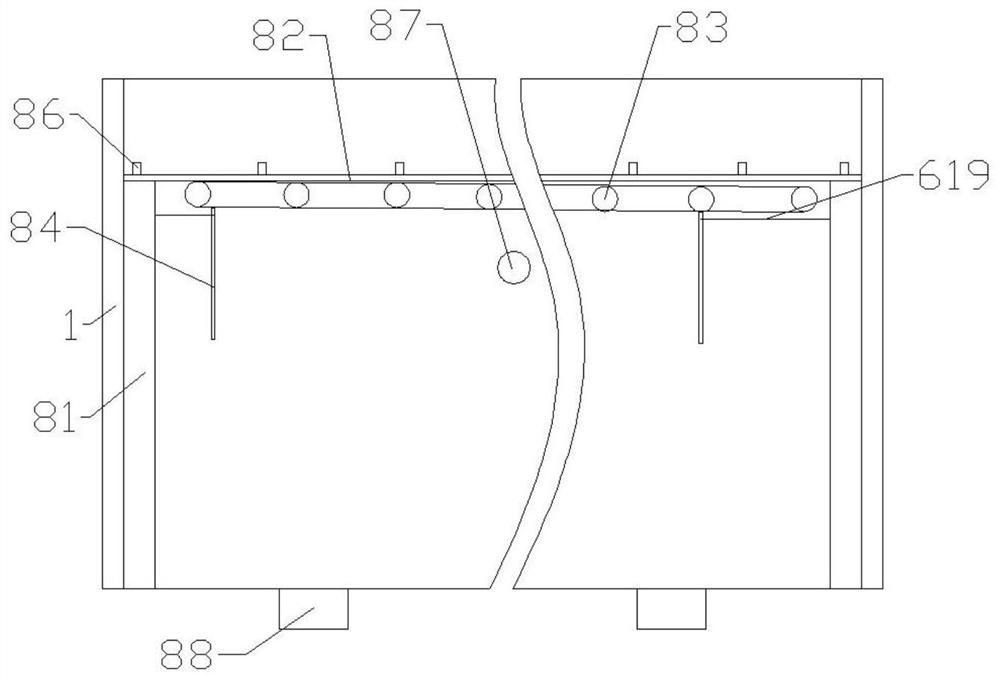

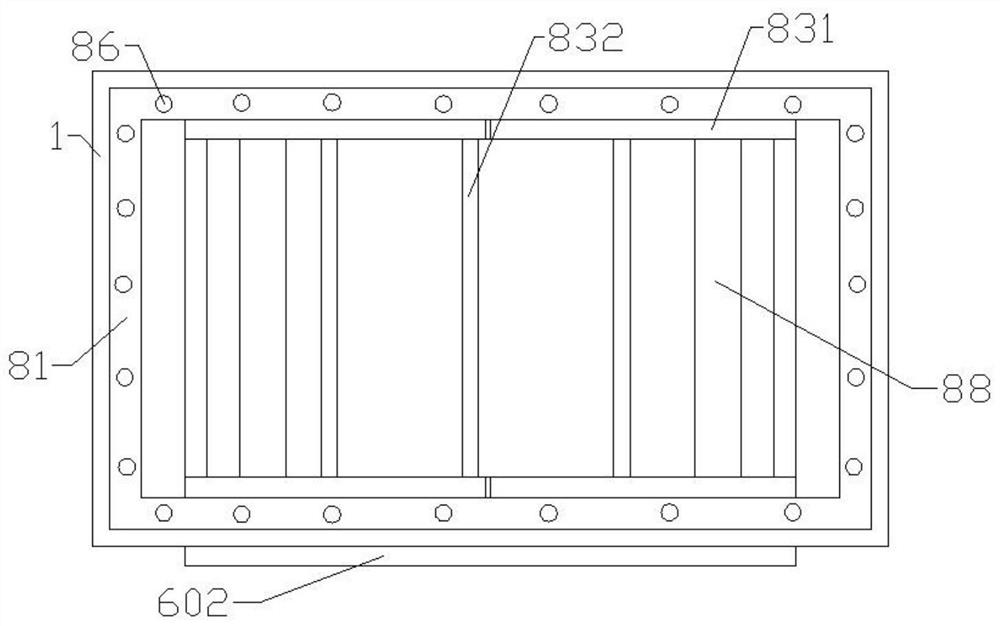

[0052] Such as Figure 1-15 As shown, a granary for green grain storage includes a granary body, the granary body includes a foundation, a wall 1 is built on the foundation, a roof 2 is built on the upper end of the wall, a door 4 is installed on the wall, and a seal is built in the granary body. The warehouse body 8, the sealed warehouse body includes the thermal insulation sealing wall 81 connected with the wall, the thermal insulation sealing wall includes the sealing coating 811, the sealing support layer 814, and the sealing insulation layer 813 which are sequentially fitted from the outside to the inside, and the thermal insulation sealing wall encloses the warehouse body, the upper end of the warehouse body is located on the upper side of the upper pipeline module and a sealing film 82 is installed, specifically, the sealing coating is coated sequentially from the outside to the inside with a cement-based permeable crystalline waterproof coating layer, a putty layer, an ...

Embodiment 2

[0072] A granary for green grain storage, such as Figure 15-16 As shown, the difference from Embodiment 1 is that the lower pipeline module includes a plurality of trenches excavated in the foundation, and the downwind pipe 882 is laid in the trench, and the upper air pipe and the lower air pipe are both processed with air holes 884. There is a step at the upper end of the trench, and there is a grid plate 881 at the step, and a filter layer 883 is laid on the grid plate. The filter layer includes a sponge layer, and a canvas layer is laid on the sponge layer. The upper end of the filter layer is flush with the foundation to avoid interference when stacking grain. Laying a filter layer can filter the airflow entering the trench.

Embodiment 3

[0074] A granary for green grain storage, such as Figure 17 As shown, the difference from Example 3 is that there are multiple downwind pipes in the same trench, the lengths of each downwind pipe are different, the ends of the downwind pipes are sealed, and there are air holes near the end of each downwind pipe, which can make the The air pressure in the trench is more uniform, which in turn makes the airflow in the sealed chamber evenly circulated and improves the efficiency of nitrogen filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com