Siphon pedestal pan without water ring

A siphonic, toilet technology, applied in flushing toilets, water supply devices, flushing equipment with water tanks, etc., can solve the problems of large flushing volume and poor flushing effect, and achieve strong flushing, clean cleaning, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

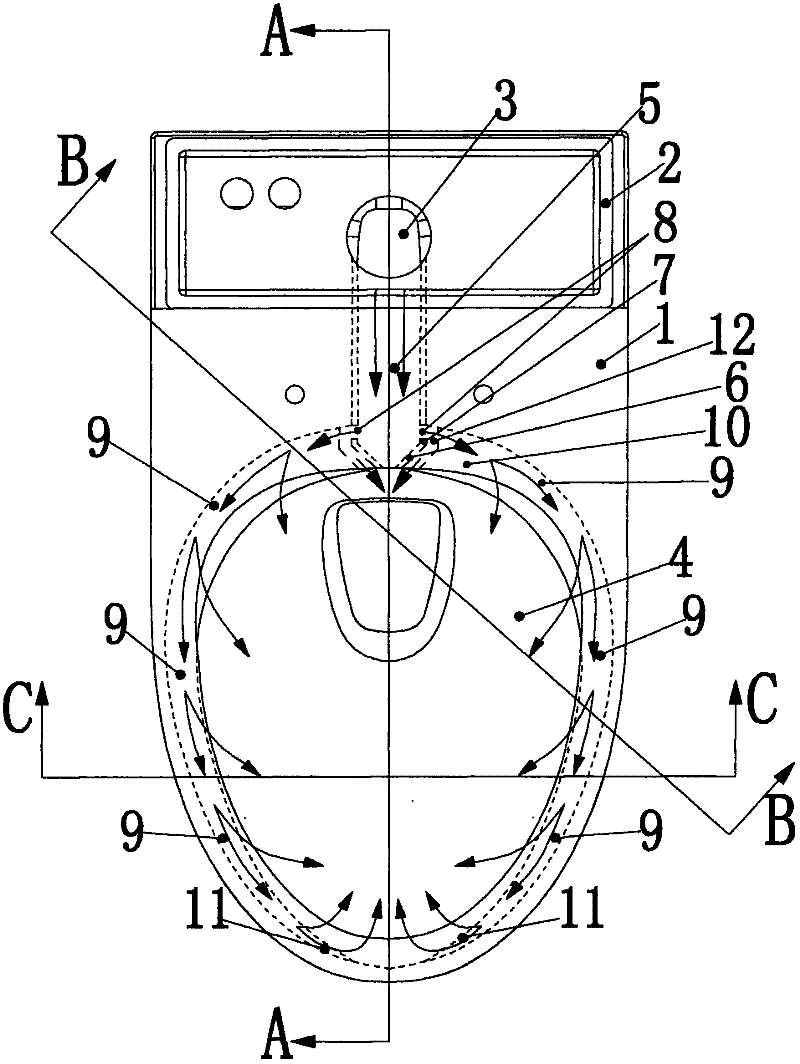

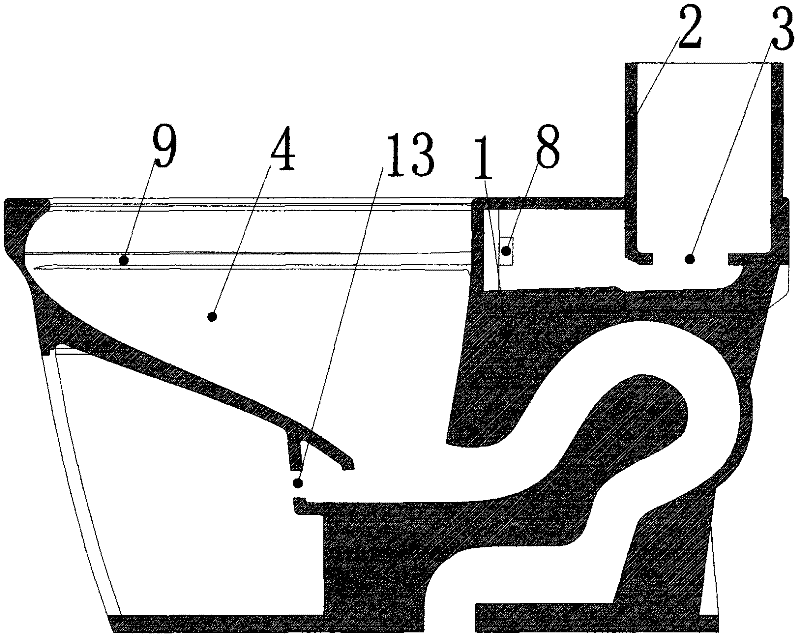

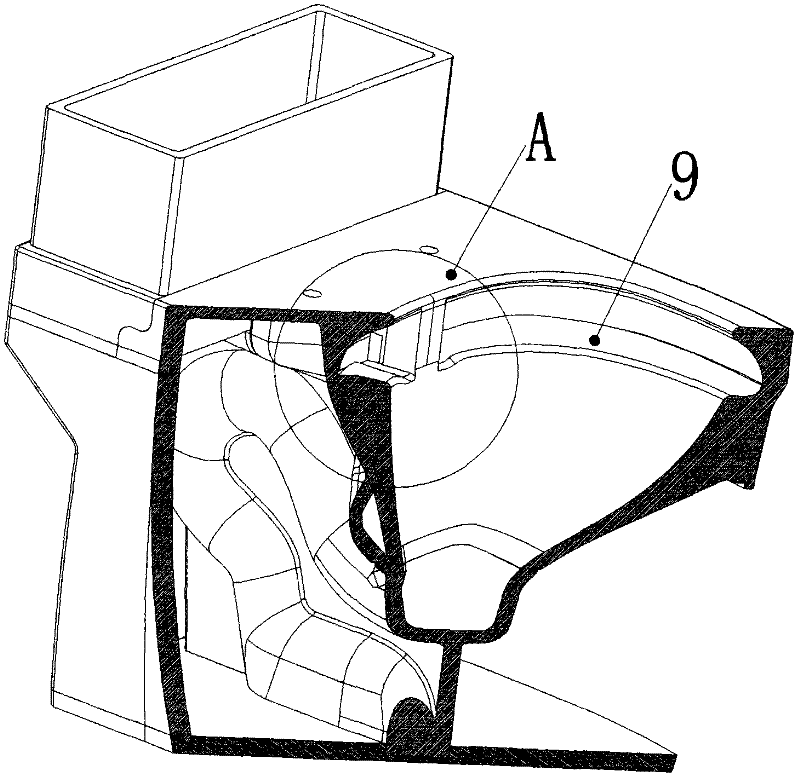

[0053] Comparative reference figure 1 , Figure 12 The difference between the second embodiment and the first embodiment lies in the end structure of the drainage channel 5 at the upper rear part of the bedpan 4. In the first embodiment, the upper end of the drainage channel 5 at the upper rear part of the bedpan 4 has two side end surfaces 7 and two oblique side end faces 6, the water spout 8 is on the two side end faces 7, and the water diversion ditch 12 is between the side end face 7 oblique side end faces 6 and the water inlet end 10 of the water diversion step 9; and in this specific embodiment two Among them, the drainage channel 5 has only two inclined side end faces 6 at the end of the upper rear part of the bedpan 4, the water spout 8 is on the two inclined side end faces 6, and the water diversion ditch 12 is on the inclined side end face 6 and the water inlet end 10 of the water diversion step 9. In between, the remaining parts are exactly the same as those in the...

specific Embodiment approach 3

[0054] Comparative reference figure 1 , Figure 13 The difference between the third embodiment and the first embodiment also lies in the end structure of the drainage channel 5 at the upper rear part of the bedpan 4. In the first embodiment, the upper end of the drainage channel 5 at the upper rear part of the bedpan 4 has two sides The end face 7 and the two oblique side end faces 6, the water spout 8 is on the two side end faces 7, and the water diversion ditch 12 is between the side end face 7 oblique side end face 6 and the water inlet end 10 of the water diversion step 9; and in this specific embodiment In the third, the drainage channel 5 has only two side end faces 7 at the end of the upper rear part of the bedpan 4, the water spout 8 is on the two side end faces 7, and the water diversion ditch 12 is between the side end faces 7 and the water inlet end 10 of the water diversion step 9 , and the rest are exactly the same as those in the first embodiment, and will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com