Installing structure of internal oil pump of electric-jet motorcycle

An installation structure and technology for motorcycles, applied in the directions of fuel injection pump, fuel injection device, charging system, etc., can solve the problems of large space occupied by the oil pump, easily affecting the appearance of the auxiliary fuel tank, and low efficiency of disassembly and assembly, so as to improve the disassembly and assembly efficiency. The effect of high installation efficiency, quick inspection and maintenance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

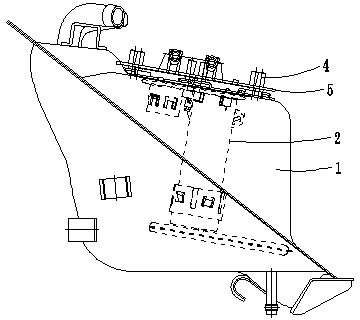

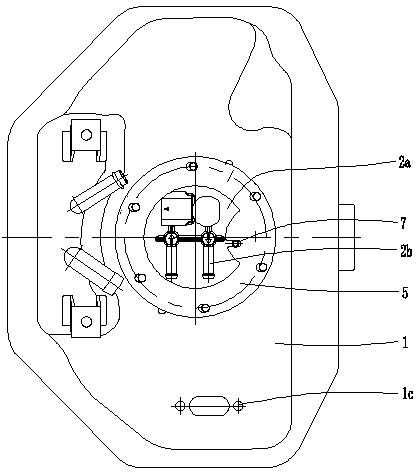

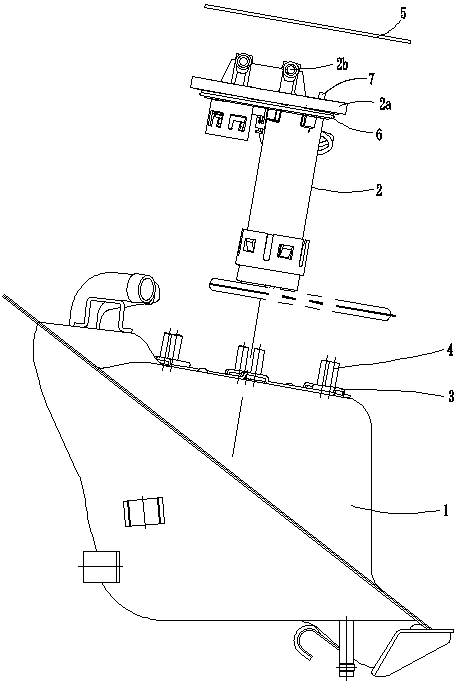

[0021] Such as Figure 1-Figure 6 As shown, the present invention is made of auxiliary oil tank 1, oil pump 2, positioning plate 3, stud 4, mounting plate 5, gasket 6 and small column 7 etc. On the top surface of the auxiliary oil tank 1 close to the right end, there are two oil level sensor installation holes 1c lined up front and back, for installing the oil level sensor. A circular assembly hole 1a is opened in the middle of the top surface of the auxiliary fuel tank 1, and a positioning plate 3 is arranged on the top surface of the auxiliary fuel tank 1. The top surface is fixed. The positioning plate 3 surrounds the outside of the mounting hole 1a, the center of the positioning plate 3 is on the center line of the mounting hole 1a, and the part of the top surface of the auxiliary fuel tank 1 between the positioning plate 3 and the mounting hole 1a forms a positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com