Light bar as well as method and mould for manufacturing light bar

A technology for light bars and molds, which is applied to lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problem of not providing optical design and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

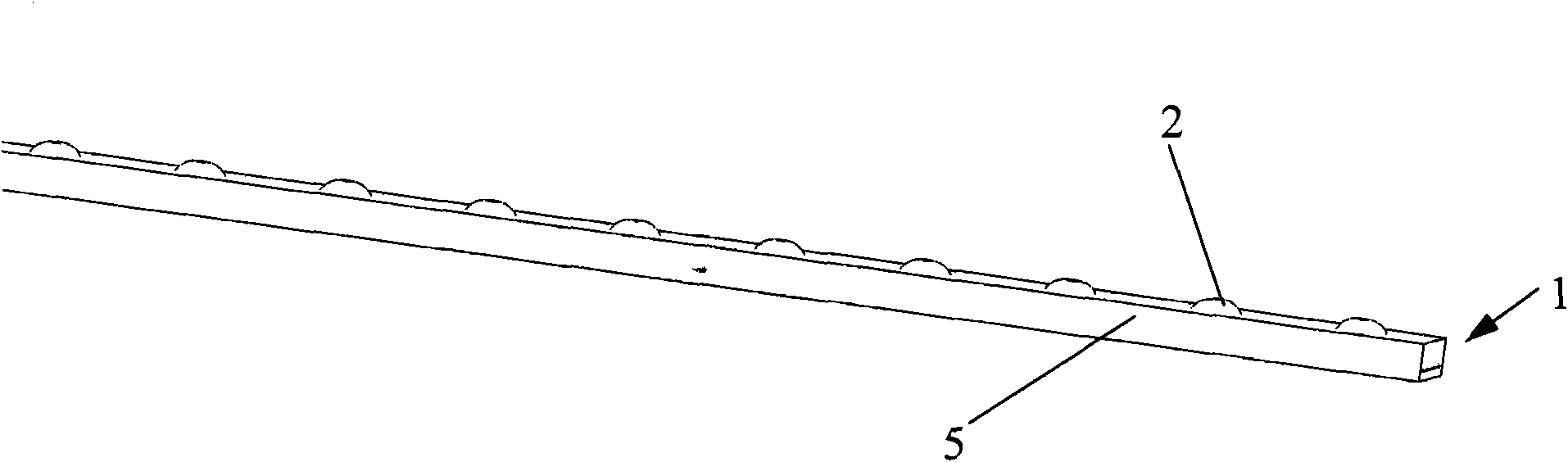

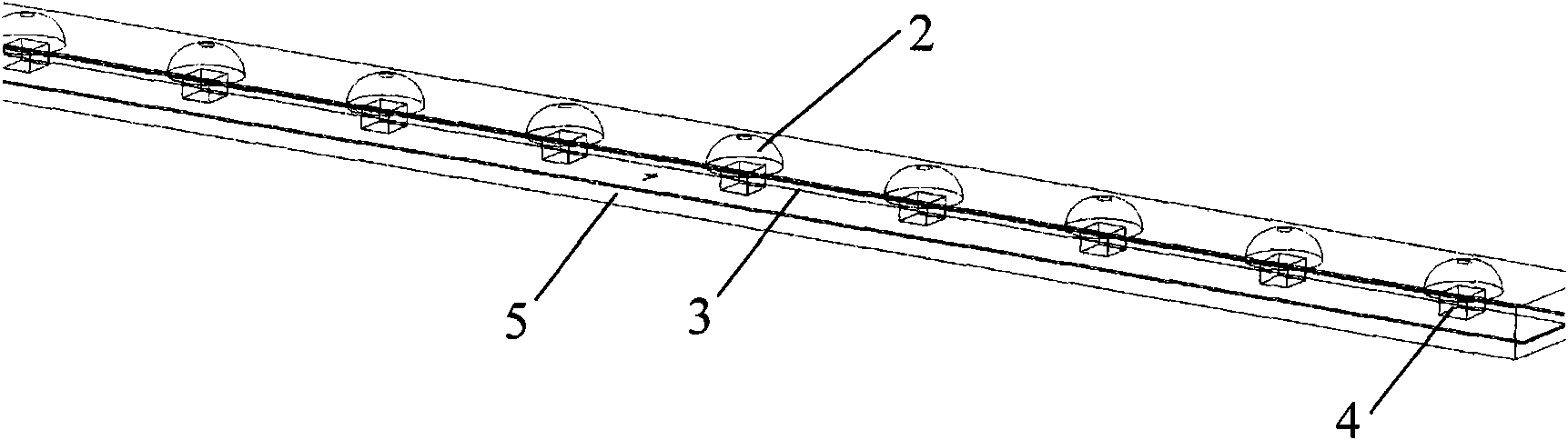

[0019] figure 1 The light bar 1 according to the invention is shown viewed from the side where the lens 2 is located. The light bar 1 includes a plurality of lenses protruding from the casing 5 distributed at intervals. The lens 2 and the housing 5 are integrally formed. The two can be made of one of PU glue and silicone. The position of the lens 2 on the outer surface is related to the LED lamp 4 on the circuit board 3 arranged in the casing 5 (an embodiment of the illuminant, image 3 The positions shown in ) are in one-to-one correspondence. This ensures that the light of the LED lamp 4 can emerge from the lens 2 and be optically adjusted, especially the light distribution.

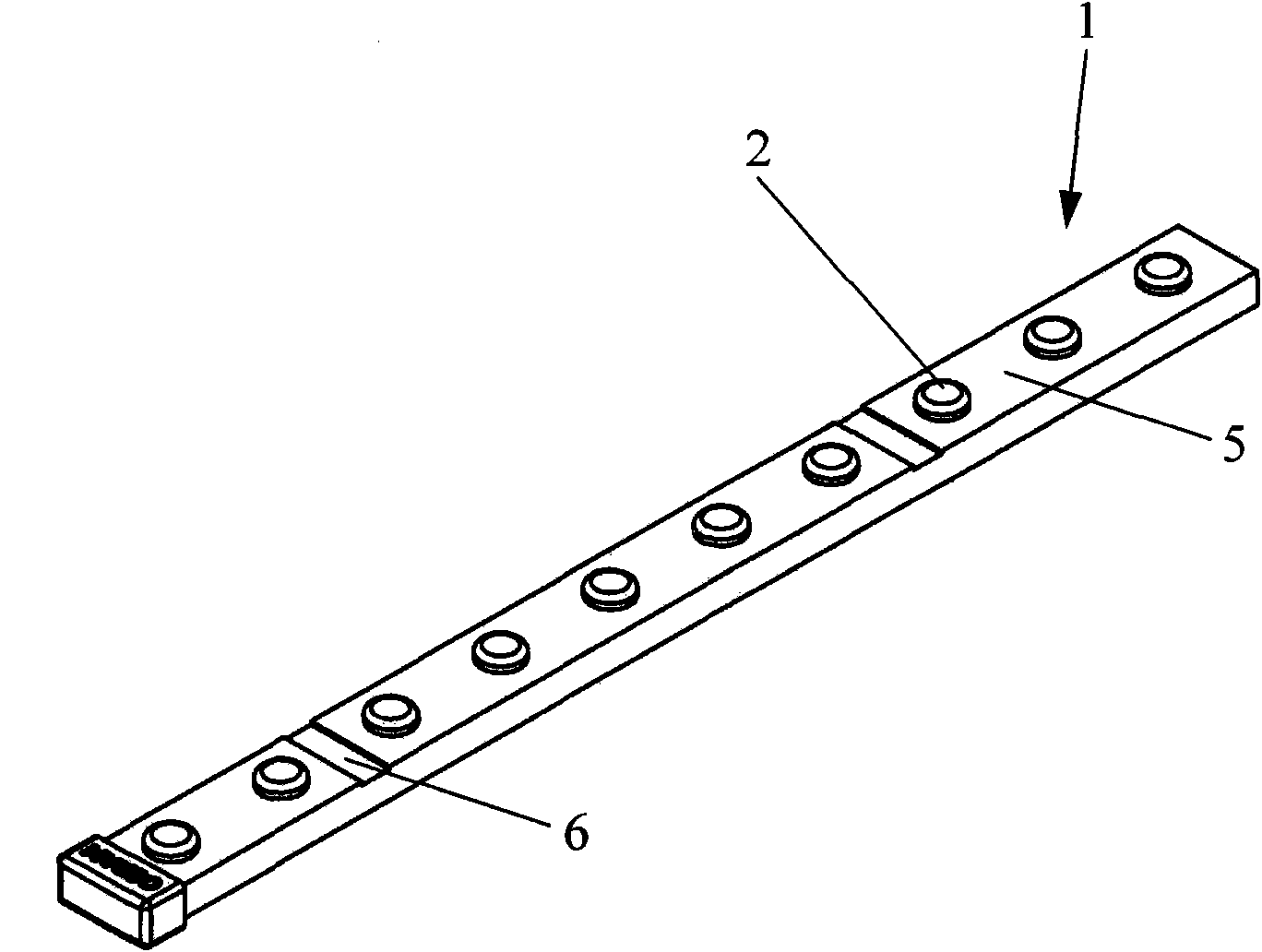

[0020] figure 2 An enlarged view of a lens and mounting part according to the present invention is shown. From the above, it can be seen clearly that a plurality of lenses 2 and a plurality of installation parts 6 disposed on the casing 5 are arranged at intervals, and the plurality of lenses 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com