Self-cleaning heat-insulating transparent film and preparation method thereof

A transparent film, self-cleaning technology, applied in the direction of biocide-containing paint, antifouling/underwater paint, coating, etc., can solve the problems of uneconomical film, no film, unrealistic and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

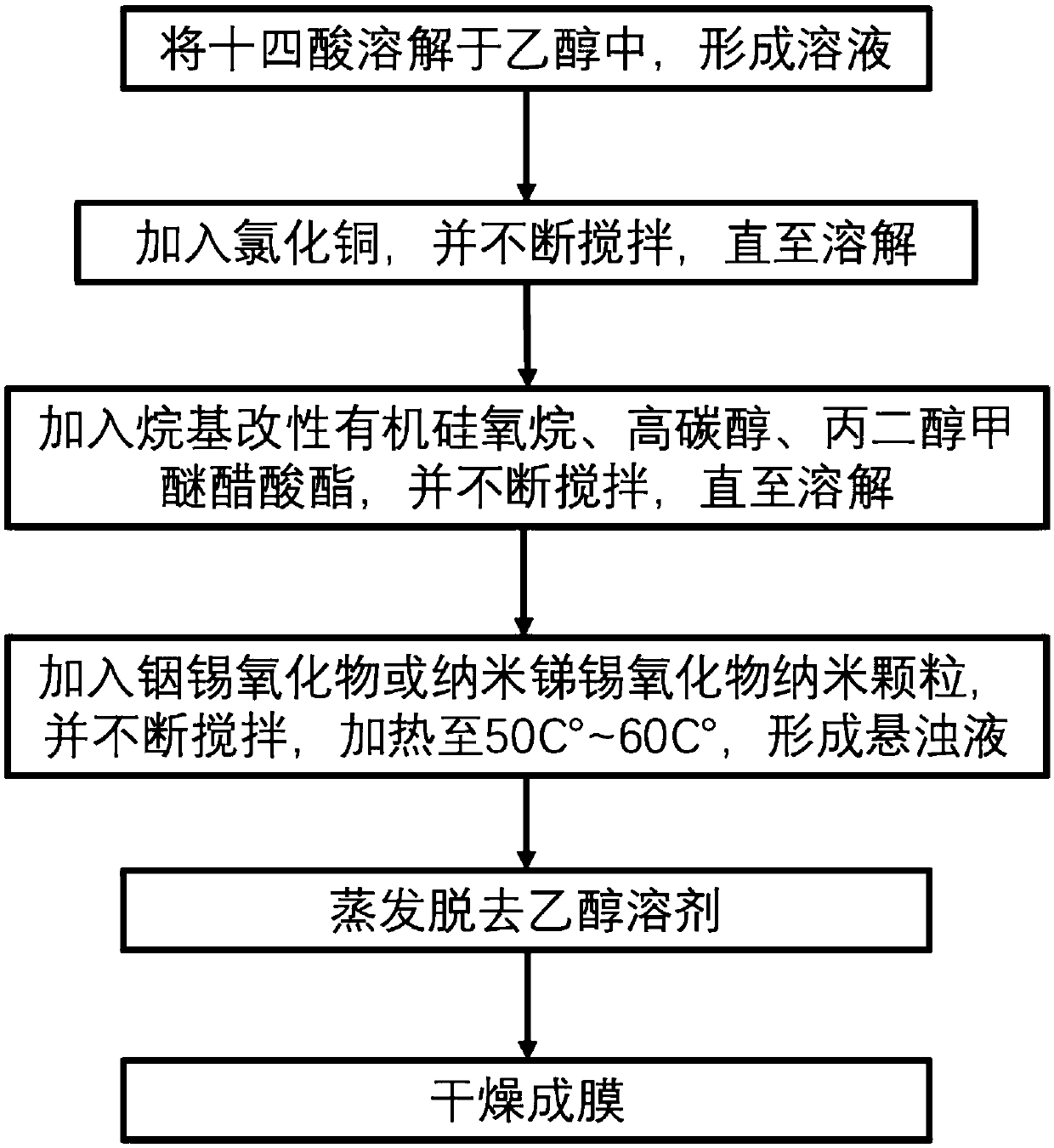

Method used

Image

Examples

Embodiment 1

[0029] A self-cleaning and heat-insulating transparent film, comprising an infrared blocking agent, a self-cleaning agent, a leveling agent, a defoamer, and a film-forming aid, and the self-cleaning agent is coated on the outer surface of the infrared blocking agent, and the weight percentage of each component is preferably of:

[0030] The infrared blocking agent contains nano-indium tin oxide, the nano-indium tin oxide is 40-80nm, and the content is 50%.

[0031] Self-cleaning agent is copper myristate at 38%

[0032] Leveling agent is alkyl modified organosiloxane, the content is 4%

[0033] The defoamer is high carbon alcohol, the content is 2%

[0034] The film-forming aid is propylene glycol methyl ether acetate with a content of 6%.

[0035] The thermal insulation rate is 70, the contact angle is 95°, and the rolling angle is 2°.

Embodiment 2

[0037] A self-cleaning and heat-insulating transparent film, comprising an infrared blocking agent, a self-cleaning agent, a leveling agent, a defoamer, and a film-forming aid, and the self-cleaning agent is coated on the outer surface of the infrared blocking agent, and the weight percentage of each component is preferably of:

[0038] The infrared blocking agent contains nano antimony tin oxide, the nano antimony tin oxide is 20-40nm, and the content is 65%.

[0039] Self-cleaning agent is copper myristate at 19%

[0040] The leveling agent is alkyl modified organosiloxane, the content is 5%

[0041] The defoamer is high carbon alcohol, the content is 3%

[0042] The film-forming aid is propylene glycol methyl ether acetate with a content of 8%.

[0043] The thermal insulation rate is 80%, the contact angle is 80°, and the rolling angle is 5°.

Embodiment 3

[0045] A self-cleaning and heat-insulating transparent film, comprising an infrared blocking agent, a self-cleaning agent, a leveling agent, a defoamer, and a film-forming aid, and the self-cleaning agent is coated on the outer surface of the infrared blocking agent, and the weight percentage of each component is preferably of:

[0046] The infrared blocking agent contains nano-indium tin oxide, the nano-indium tin oxide is 40-100nm, and the content is 40%.

[0047] Self-cleaning agent is copper myristate at 45%

[0048] The leveling agent is alkyl modified organosiloxane, the content is 5%

[0049] The defoamer is high carbon alcohol, the content is 3%

[0050] The film-forming aid is propylene glycol methyl ether acetate with a content of 7%.

[0051] The thermal insulation rate is 65%, the contact angle is 97°, and the rolling angle is 2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com