Supramolecular assembly modified ammonium polyphosphate and preparation method thereof

An ammonium polyphosphate and supramolecular technology, applied in the field of flame retardant materials, can solve the problems of unsuitability for large-scale industrial production, high cost of silane coupling agent, easy loss of coating effect, etc., to improve quality and improve compatibility. , the effect of slowing down the combustion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of supramolecular assembly modified ammonium polyphosphate of the present invention:

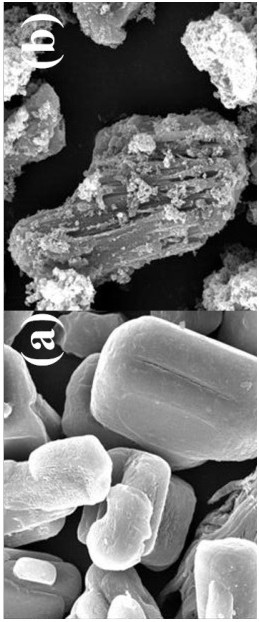

[0020] Add 35-40% formaldehyde solution into the melamine and mix thoroughly to adjust the pH value of the mixture to 8-9. Under the condition of 80-90 ℃ oil bath, mechanically stir for 20-30 minutes to fully react to form a transparent prepolymer prepolymer. Add the prepolymer to the ammonium polyphosphate aqueous solution, and adjust the pH value of the mixed solution to 4-5. Heat the mixed solution in an oil bath at 80-90 °C, add organic acid to it, and stir mechanically for 1-2 h. The ammonium polyphosphate powder modified by supramolecular assembly can be obtained after the product is filtered and washed 5 to 6 times, dried, and ground.

example 1

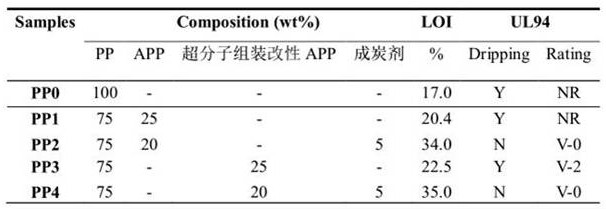

[0022] 25 g of commercially available APP and 75 g of polypropylene were melt-blended to prepare a standard experimental test sample of polypropylene composite material, denoted as PP1.

example 2

[0024] 20 g of commercially available APP, 5 g of commercially available charcoal agent and 75 g of polypropylene were melt-blended to prepare a standard experimental test sample of polypropylene composite material, which was denoted as PP2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com