Aerogel-modified high-strength fireproof mortar material and preparation method thereof

A mortar material and airgel technology, applied in the field of building materials, can solve the problems of threatening people's life and property safety, poor thermal insulation effect, high thermal conductivity, etc., and achieve excellent mechanical properties, good fire resistance, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

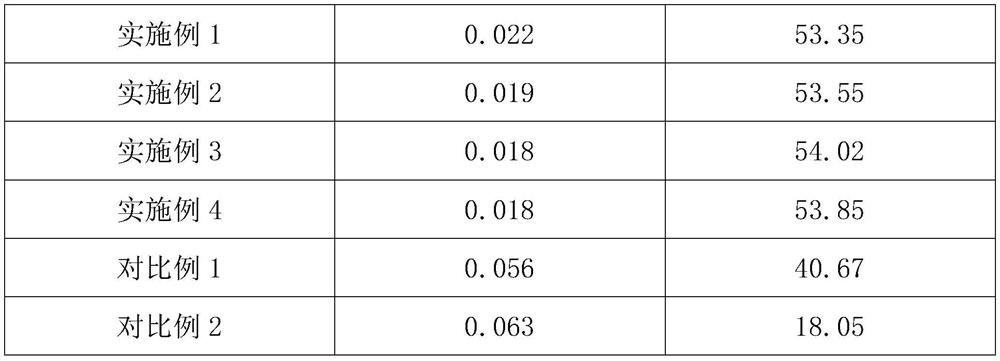

Examples

Embodiment 1

[0039] (1) Mix 0.2g melamine and 15ml concentration of 8mg / ml graphene oxide solution, then add 1ml mass concentration of 37% formaldehyde solution, add 0.1g nano-titanium dioxide after mixing, and place the prepared mixed solution in The reaction was carried out in the autoclave at 180°C for 10 hours. After the reaction, the solid was separated and dried, and then placed in a muffle furnace. Under an oxygen-free nitrogen atmosphere, the temperature was first raised to 800°C at a rate of 10°C / min for 3 hours. Then the temperature was lowered to 600°C at a rate of 3°C / min, heat preservation treatment was carried out for 2 hours, and finally cooled to room temperature with the furnace to prepare nano-titanium dioxide modified with nitrogen-doped graphene airgel;

[0040] (2) Mix and stir 0.2g zirconium oxychloride, 1ml tetraethyl orthosilicate, 15ml dehydrated alcohol and 20ml deionized water evenly to obtain a silicon / zirconium composite sol, and add the above-mentioned 10g nitr...

Embodiment 2

[0043] (1) Mix 0.4g melamine and 15ml concentration of 15mg / ml graphene oxide solution, then add 1ml mass concentration of 37% formaldehyde solution, add 0.2g nano-titanium dioxide after mixing, and place the prepared mixed solution in The reaction was carried out at 180°C in the autoclave for 15 hours. After the reaction, the solid was separated and dried, and then placed in a muffle furnace. Under an oxygen-free nitrogen atmosphere, the temperature was first raised to 800°C at a rate of 10°C / min for 3 hours. Then the temperature was lowered to 600°C at a rate of 3°C / min, heat preservation treatment was carried out for 2 hours, and finally cooled to room temperature with the furnace to prepare nano-titanium dioxide modified with nitrogen-doped graphene airgel;

[0044] (2) Mix and stir 0.4g zirconium oxychloride, 1ml tetraethyl orthosilicate, 15ml absolute ethanol and 20ml deionized water evenly to obtain a silicon / zirconium composite sol, add the nitrogen-doped graphene prepa...

Embodiment 3

[0047] (1) Mix 0.3g melamine and 15ml concentration of 10mg / ml graphene oxide solution, then add 1ml mass concentration of 37% formaldehyde solution, add 0.15g nano-titanium dioxide after mixing, and place the prepared mixed solution in The reaction was carried out at 180°C in the autoclave for 11 hours. After the reaction, the solid was separated and dried, and then placed in a muffle furnace. Under an oxygen-free nitrogen atmosphere, the temperature was first raised to 800°C at a rate of 10°C / min for 3 hours. Then the temperature was lowered to 600°C at a rate of 3°C / min, heat preservation treatment was carried out for 2 hours, and finally cooled to room temperature with the furnace to prepare nano-titanium dioxide modified with nitrogen-doped graphene airgel;

[0048] (2) Mix and stir 0.3g zirconium oxychloride, 1ml tetraethyl orthosilicate, 15ml absolute ethanol and 20ml deionized water evenly to obtain a silicon / zirconium composite sol, and add the above-mentioned 10g nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com