Low-smoke halogen-free polyolefin cable material capable of being ceramized at high temperature and preparation method of low-smoke halogen-free polyolefin cable material

A polyolefin cable material and ceramicization technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of high cost of refractory materials, limited application, complex processing and production processes, etc., to achieve high hardness, overall The effect of good fastening and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

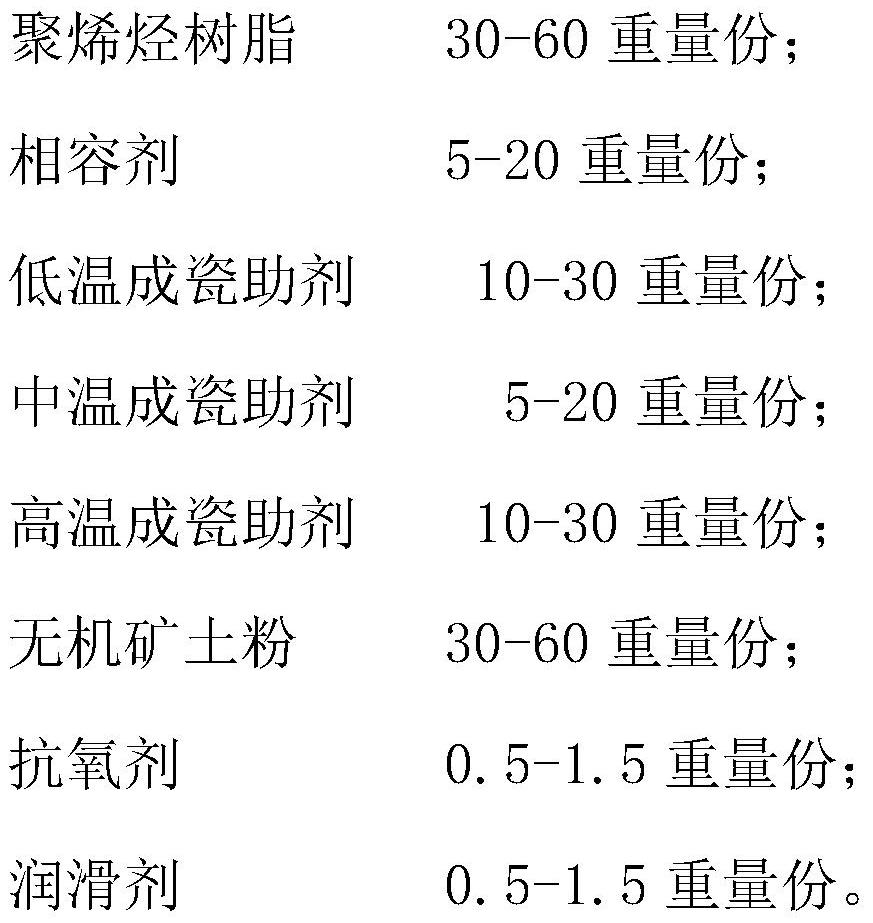

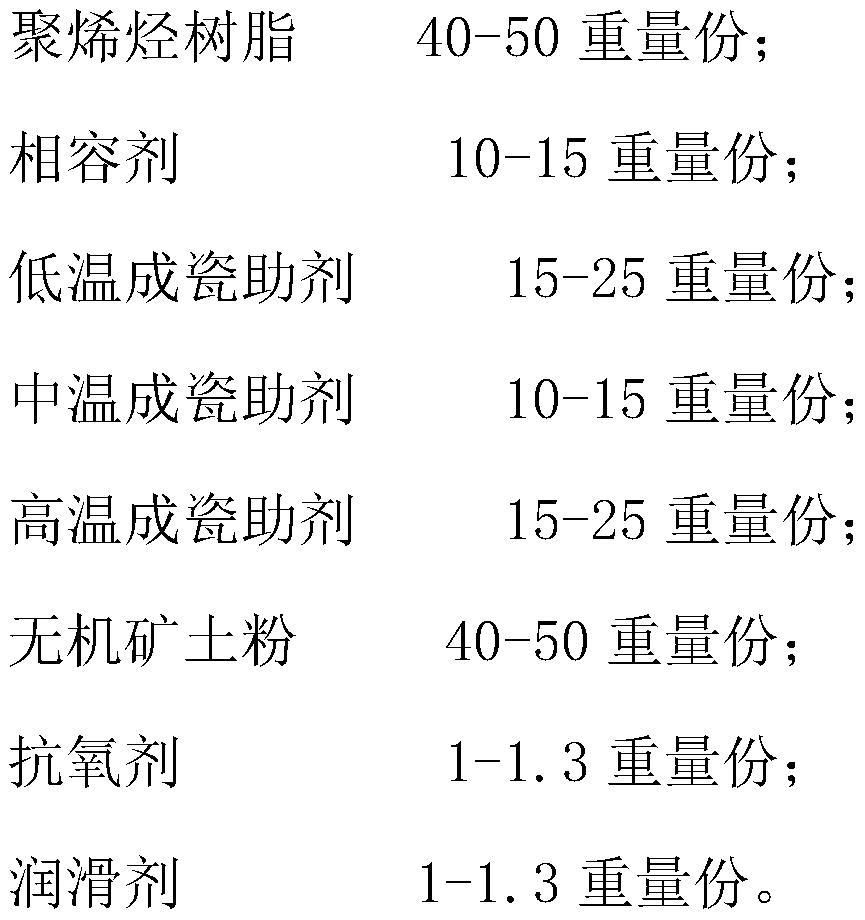

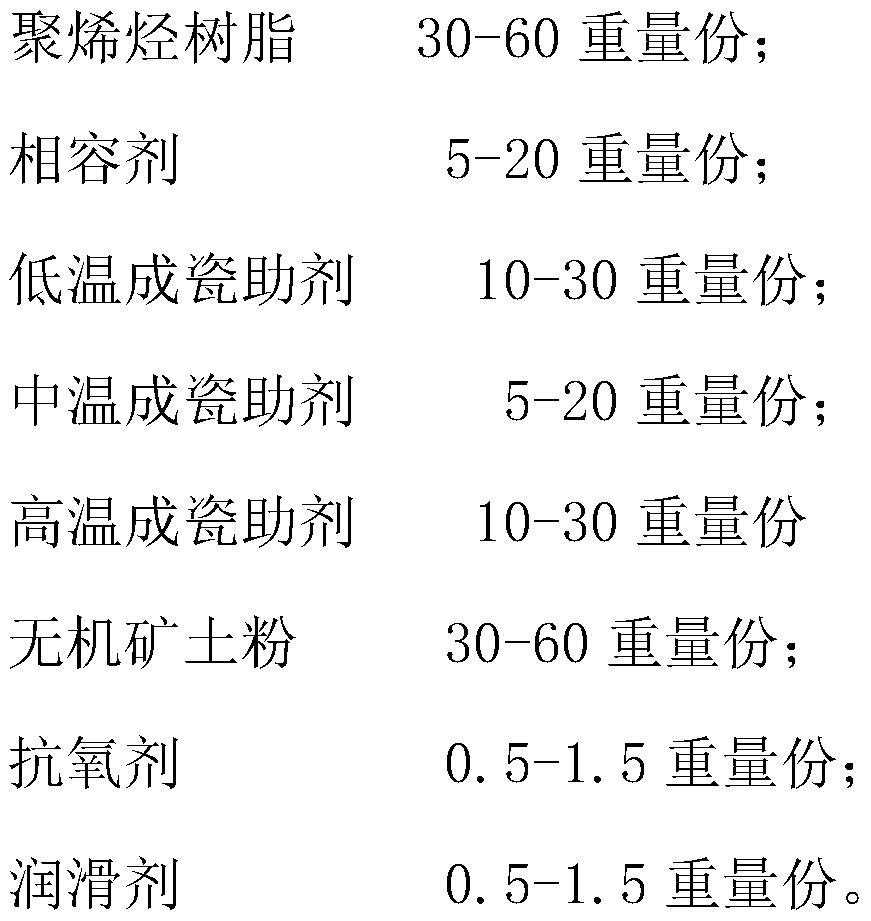

[0040]A high-temperature ceramizable low-smoke halogen-free polyolefin cable material is composed of the following raw materials in parts by weight: 20 parts by weight of polyethylene resin, 20 parts by weight of polyolefin elastomer, 10 parts by weight of polyethylene compatibilizer, low-temperature synthetic 20 parts by weight of ceramic additives, 10 parts by weight of medium-temperature ceramic-forming additives, 20 parts by weight of high-temperature ceramic-forming additives, 50 parts by weight of inorganic powder, and 1 part by weight of antioxidant. 1 part by weight of lubricant.

[0041] Use torque rheometer for melt plasticization, plasticizing temperature is 160°C, use plate fluidizer for tableting sample preparation, tableting temperature is 160°C, hold pressure for 10 minutes, pressurize for 5 minutes, cool for 5 minutes

Embodiment example 2

[0043] A high-temperature ceramizable low-smoke halogen-free polyolefin cable material is composed of the following raw materials in parts by weight: 15 parts by weight of polyethylene resin, 20 parts by weight of polyolefin elastomer, 20 parts by weight of polyethylene compatibilizer, low-temperature synthetic 15 parts by weight of ceramic additive, 5 parts by weight of medium-temperature ceramic-forming additive, 30 parts by weight of high-temperature ceramic-forming additive, 55 parts by weight of inorganic powder, and 1 part by weight of antioxidant. 1 part by weight of lubricant.

[0044] Use torque rheometer for melt plasticization, plasticizing temperature is 160°C, use plate fluidizer for tableting sample preparation, tableting temperature is 160°C, hold pressure for 10 minutes, pressurize for 5 minutes, cool for 5 minutes

Embodiment example 3

[0046] A high-temperature ceramizable low-smoke halogen-free polyolefin cable material is composed of the following raw materials in parts by weight: 10 parts by weight of polyethylene resin, 30 parts by weight of polyolefin elastomer, 15 parts by weight of polyethylene compatibilizer, low-temperature synthetic 15 parts by weight of ceramic auxiliary agent, 10 parts by weight of medium-temperature porcelain-forming auxiliary agent, 25 parts by weight of high-temperature porcelain-forming auxiliary agent, 55 parts by weight of inorganic powder, and 1 part by weight of antioxidant. 1 part by weight of lubricant.

[0047] Melting plasticization was carried out by using a torque rheometer, the plasticizing temperature was 160°C, and the flat plate fluidizer was used for tableting sample preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com