Water-saving valve

A water-saving valve and water tank technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of high water pressure requirements, inability to clean the inner upper wall of the toilet, low water pressure, etc., and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

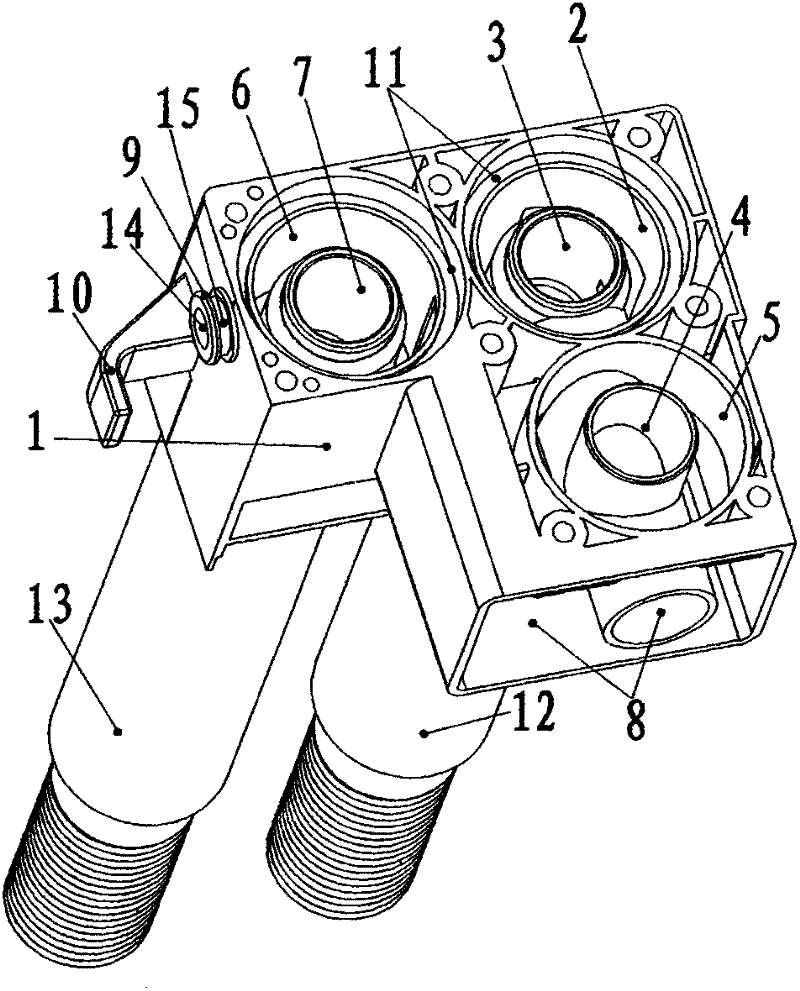

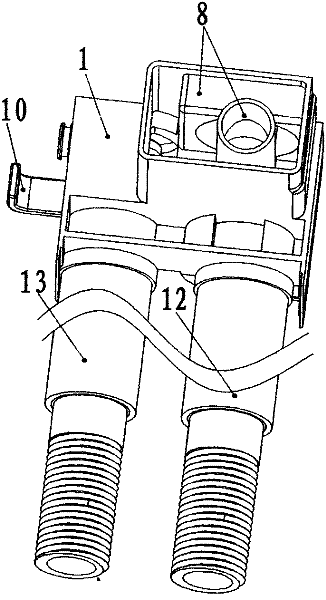

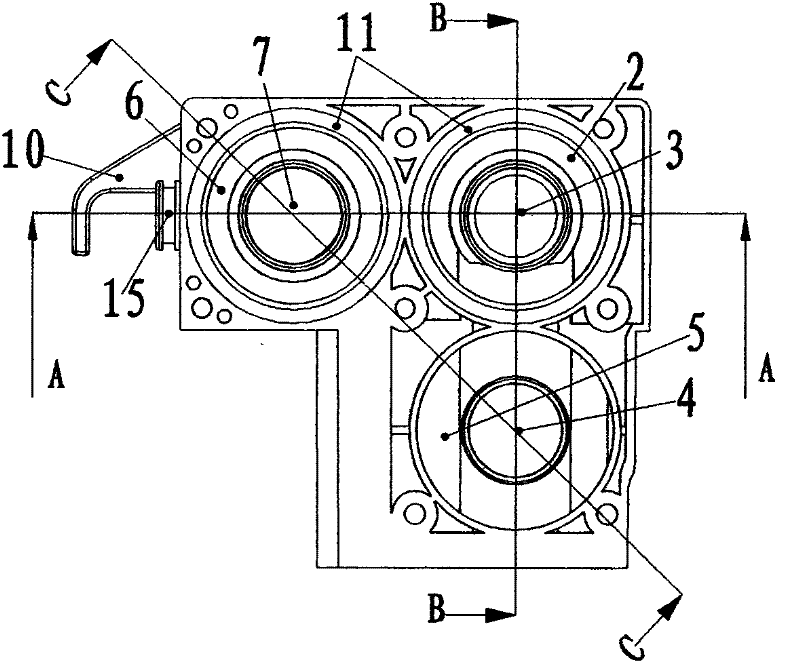

[0088] refer to Figure 1a , Figure 1b , Figure 1c , on the main valve body 1 there are main valve inlet chamber 2, main valve outlet chamber 3, anti-siphon valve inlet chamber 4, anti-siphon valve outlet chamber 5, auxiliary valve inlet chamber 6, auxiliary valve outlet chamber 7, Mold cavity 8, water outlet head 9, water outlet joint hook 10, valve core seat 11, water inlet pipe 12, spray pipe 13, water outlet 14 and sealing ring groove 15.

[0089] Wherein, the water inlet pipe 12 is parallel to the spray pipe 13 .

[0090] refer to Figure 2a , Figure 2b , Figure 2c , the water inlet pipe 12 communicates with the main valve inlet chamber 2, the main valve outlet chamber 3 communicates with the anti-siphon valve inlet chamber 4, the anti-siphon valve outlet chamber 5 communicates with the auxiliary valve inlet chamber 6, and the auxiliary valve outlet chamber 7 communicates with the spray pipe 13, and the water inlet cavity 6 of the auxiliary valve communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com