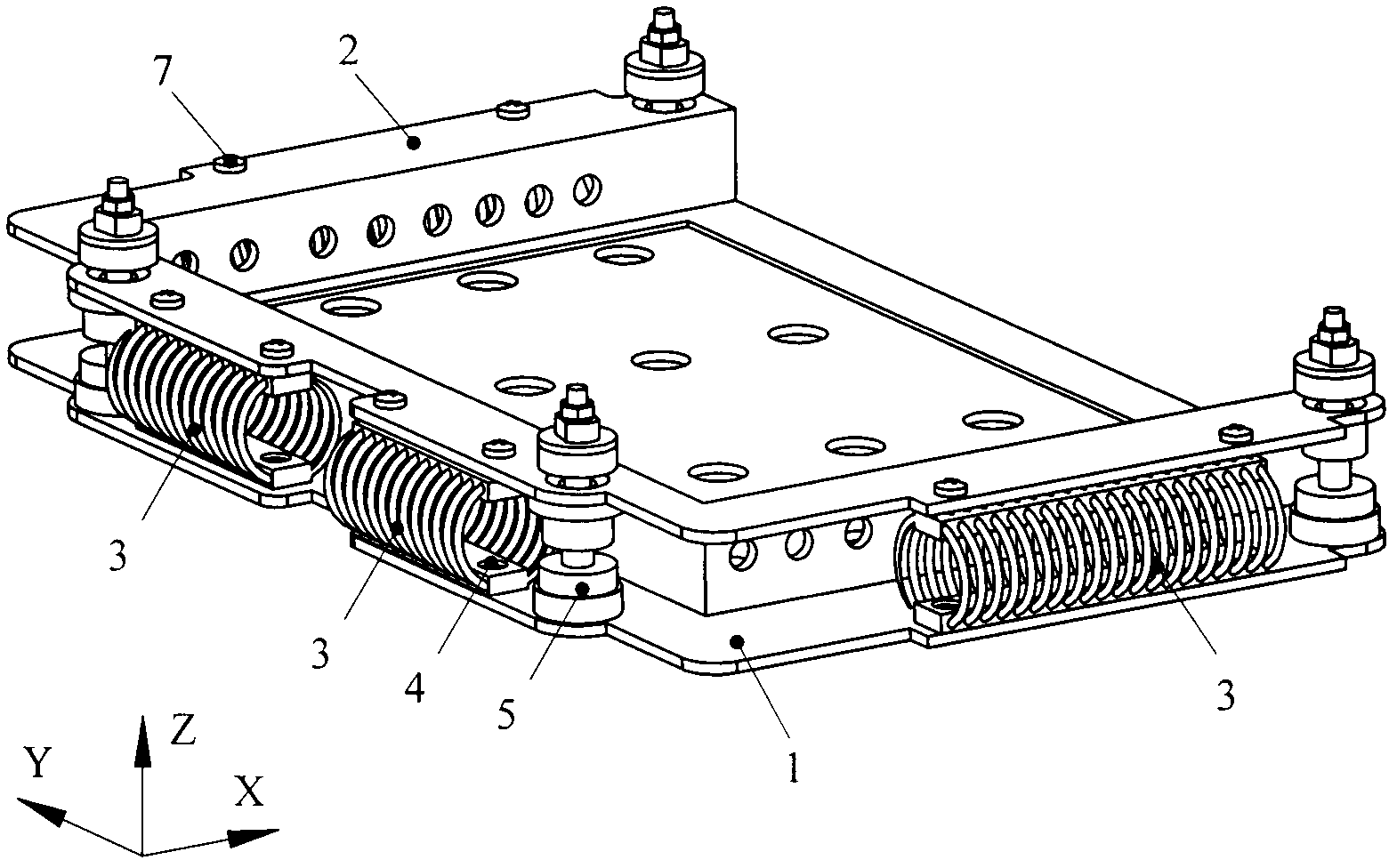

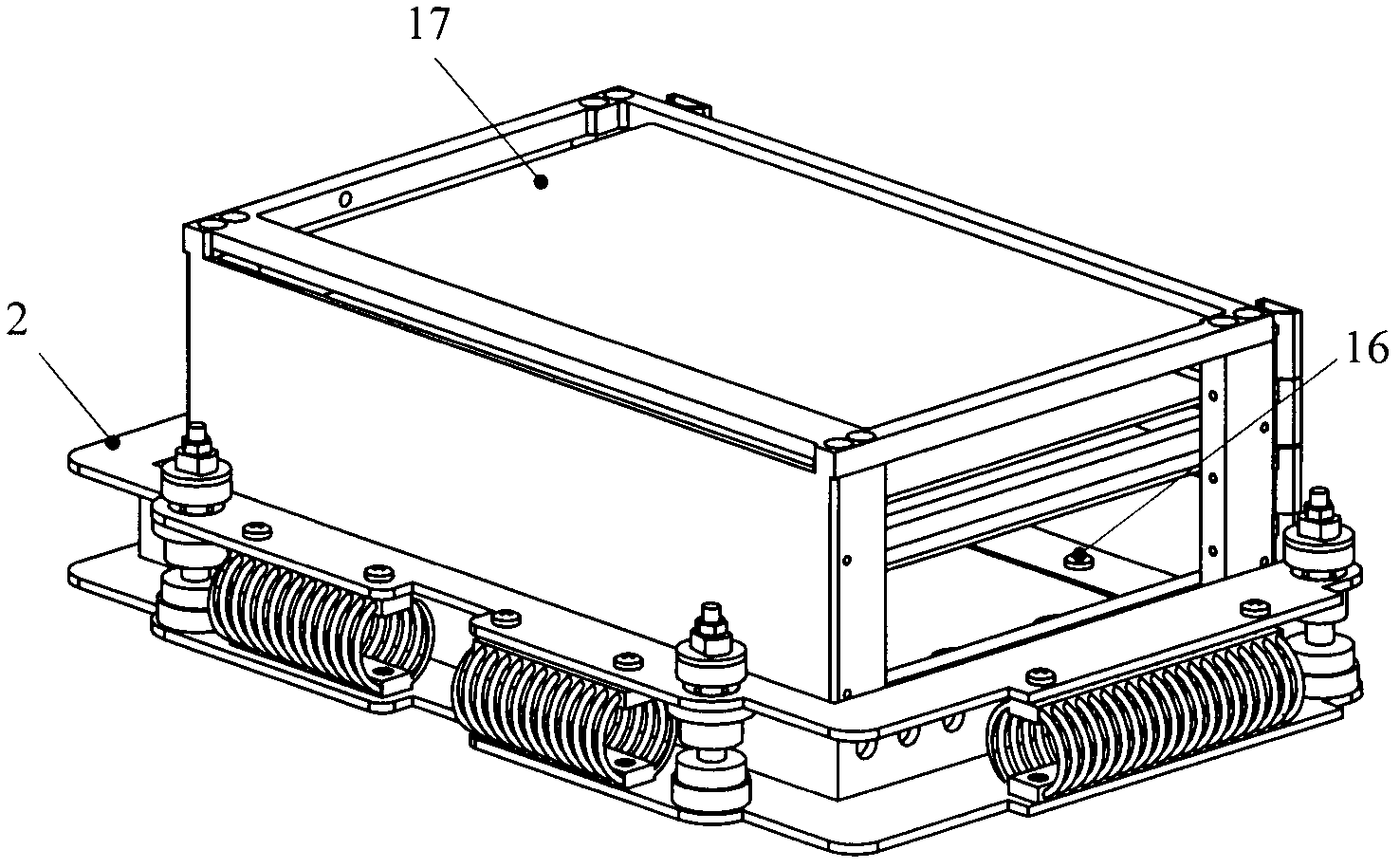

Compound vibration-isolating and buffering device

A buffer device and composite technology, applied in the direction of high internal friction springs, etc., can solve the problems of good buffering effect, achieve high vibration isolation efficiency, optimize vibration isolation buffer design, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

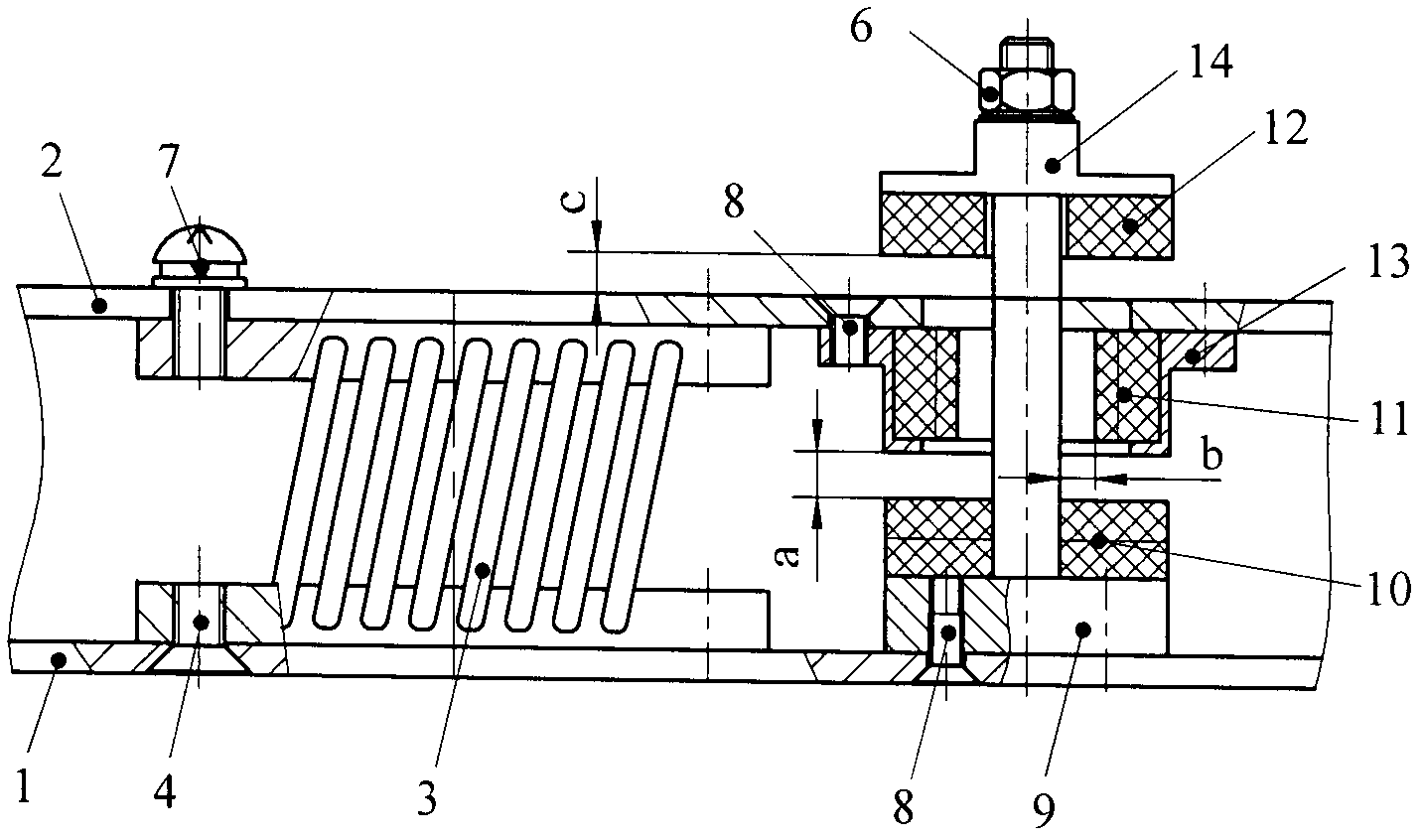

Embodiment Construction

[0015] Selection of design parameters: Given the shock test spectrum with different impact time, steel wire ropes and rubber shock absorbers with different natural frequencies will amplify or weaken the shock, and the natural frequency depends to a large extent on the average stiffness of the shock absorber , so the average stiffness of the first and second orders should be determined first. In the first-order vibration reduction, according to the load, vibration and impact test parameters, the average stiffness and energy capacity in three directions of the required first-order wire rope shock absorber, as well as the maximum displacement response at the first-order resonance and the given shock condition can be obtained. shock response. Then, the average stiffness of the second-order rubber damping is obtained according to the installation space required by the equipment and the maximum impact the system can withstand.

[0016] The stiffness curve of the device has a sudden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com