Vehicle braking device

A braking device and vehicle technology, applied in the direction of control device, brake, control drive, etc., can solve problems such as passenger discomfort, and achieve the effect of preventing the generation of whine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

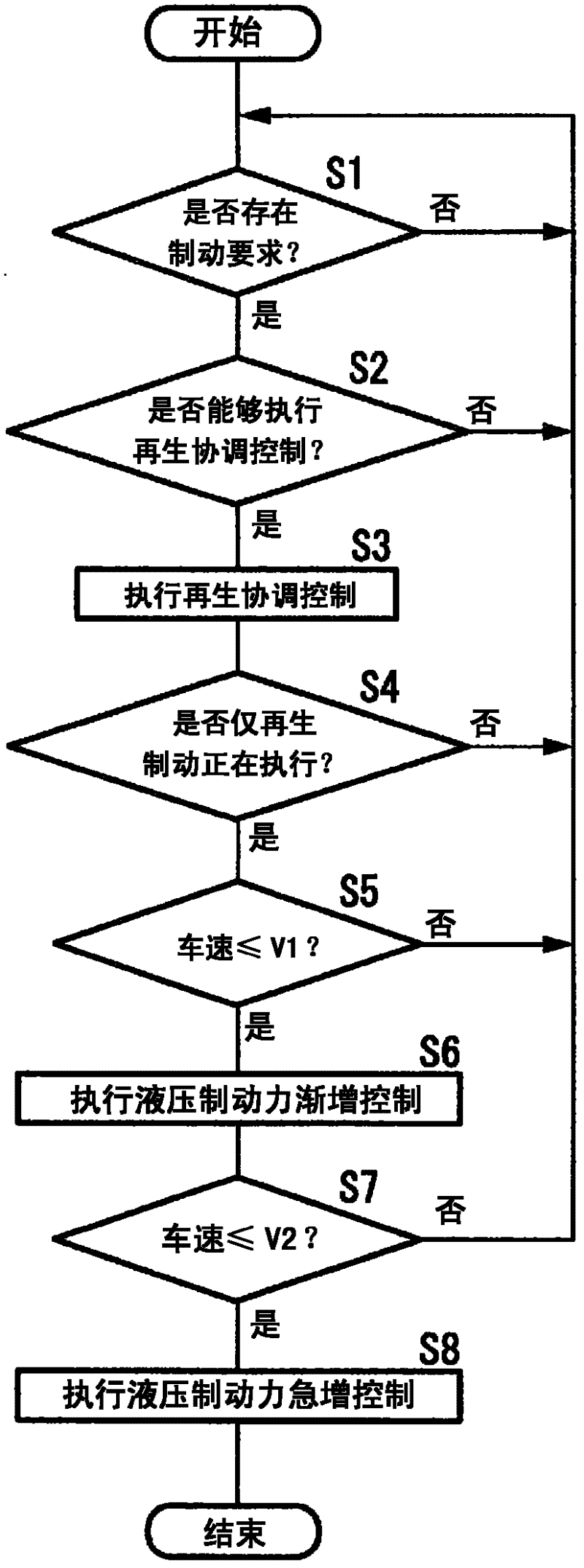

Examples

no. 1 approach

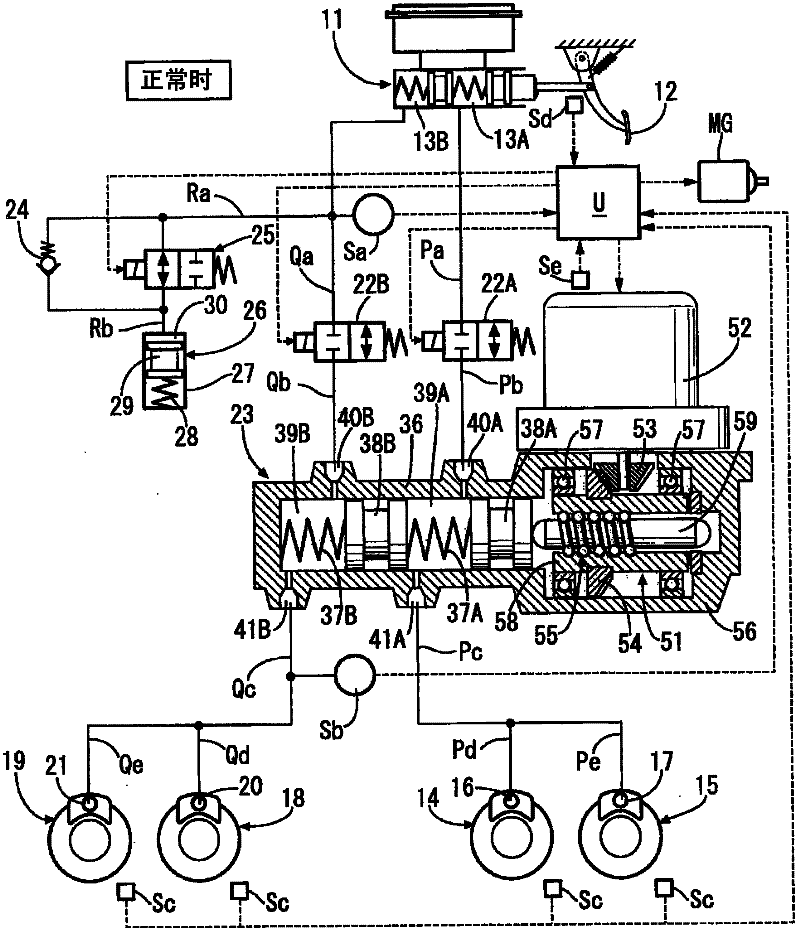

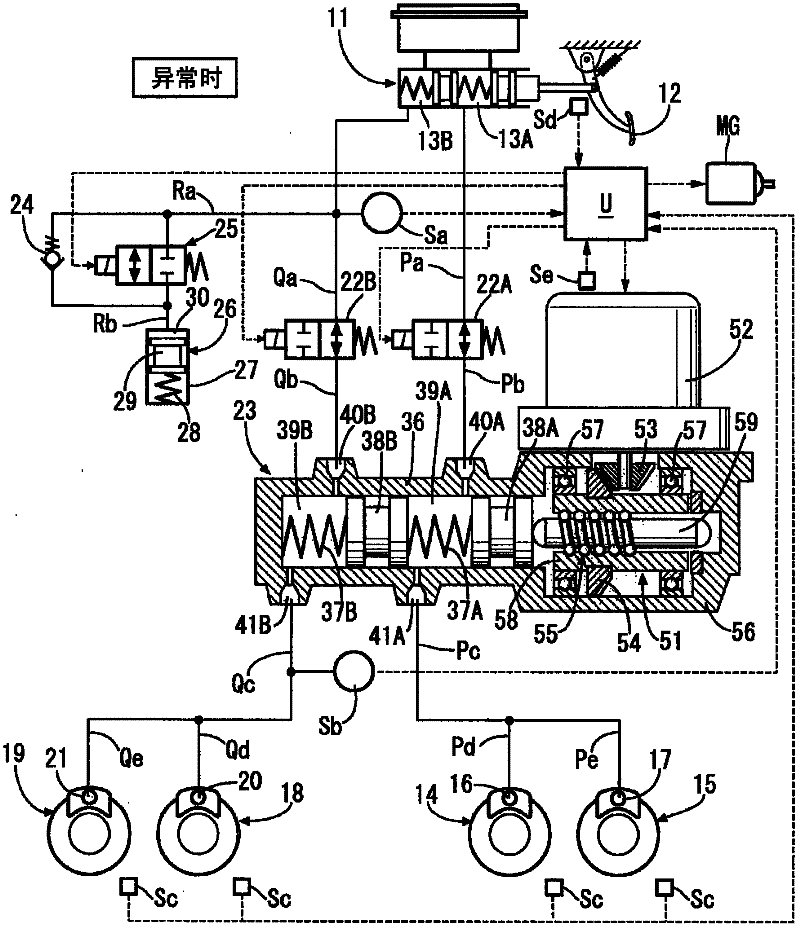

[0032] Such as figure 1 As shown, the tandem-type master hydraulic cylinder 11 is provided with a sub-hydraulic chamber 13A and a main hydraulic chamber 13B that output brake hydraulic pressure corresponding to the driver's depressing force on the brake pedal 12, and the sub-hydraulic chamber 13A passes through the hydraulic passages Pa, Pb . Qe is connected to the wheel cylinders 20, 21 of the disc brake devices 18, 19 of the right front wheel and the left rear wheel, for example.

[0033] An on-off valve 22A as a normally open electromagnetic valve is arranged between the liquid paths Pa and Pb, and an on-off valve 22B as a normally open electromagnetic valve is arranged between the liquid paths Qa and Qb. A slave hydraulic cylinder 23 is arranged between the hydraulic passages Pc and Qc. Further, a stroke simulator 26 is connected to the hydraulic passages Ra and Rb branched from the hydraulic passage Qa extending from the main hydraulic chamber 13B via a reaction force a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com