Turbocharger

A technology of turbochargers and turbines, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as tolerance wear and achieve the effect of reducing wear and minimizing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

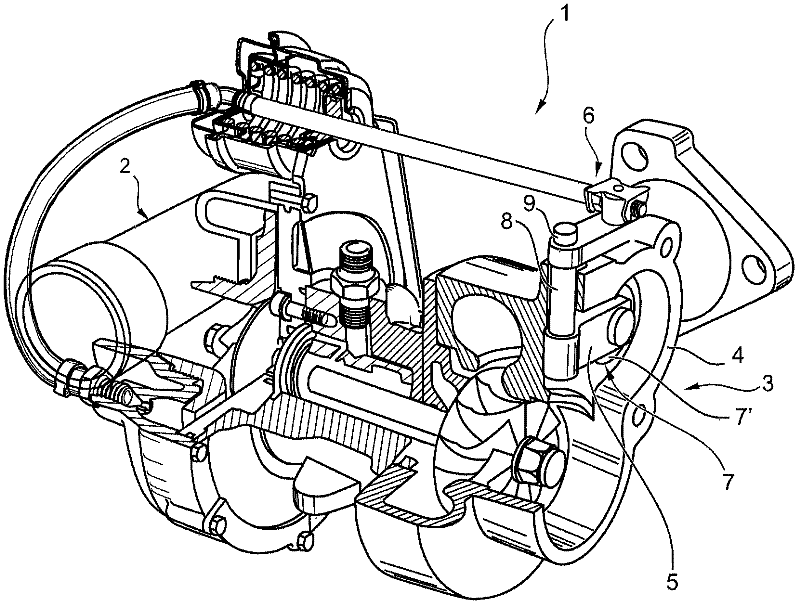

[0016] figure 1 A turbocharger 1 is shown, which includes a compressor 2 and a turbine 3 . The turbine 3 includes a turbine housing 4 and a wastegate arrangement 6 with adjusting flaps 7 . The adjusting flap 7 comprises a flap 7' which is arranged via a lever 5 on an adjusting flap shaft 9 which is guided in the turbine housing 4 via a bush 8.

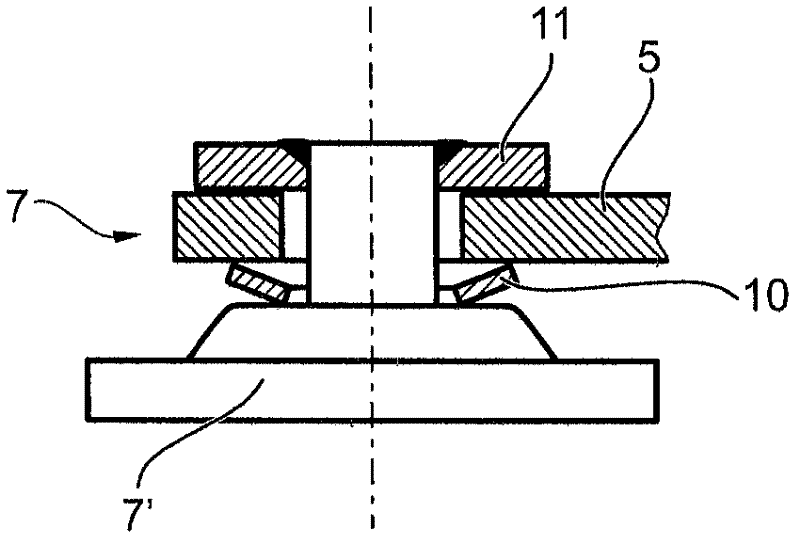

[0017] as from figure 2 It can be seen that the flap 7' is preloaded against the lever 5 by a spring element 10. In the first embodiment, the spring element 10 is arranged between the flap 7' and the lever 5.

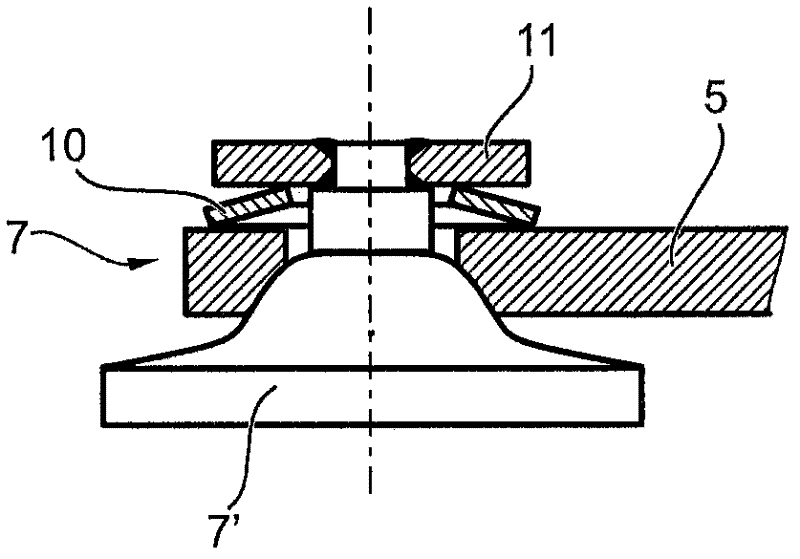

[0018] exist image 3 In the second embodiment, the spring element 10 is arranged between the lever 5 and a disc 11 connected to the flap 7'.

[0019] In both design variants, the connection between the disc 11 and the flap 7' can be a gapless welded or riveted connection. According to the invention, the spring element 10 can have different spring shapes. as in Figure 4 As shown, the spring ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap