Illuminating device for plant cultivation and plant cultivation system

A lighting device and plant technology, applied in the field of plant cultivation systems, can solve the problems of rapid deterioration, shortened life, unoptimized and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

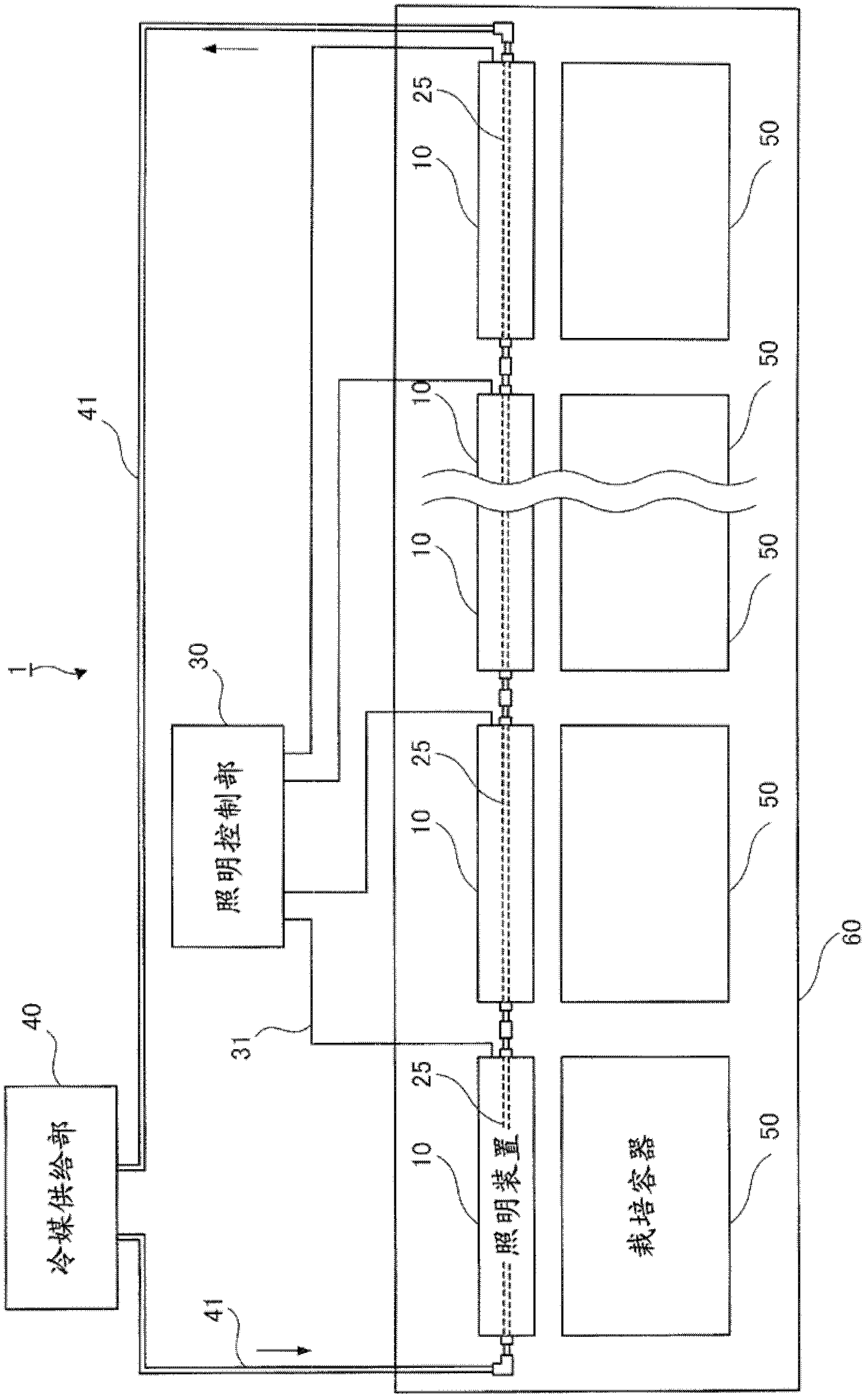

[0040] figure 1 It is a figure which shows an example of the plant cultivation system 1 to which this embodiment is applied.

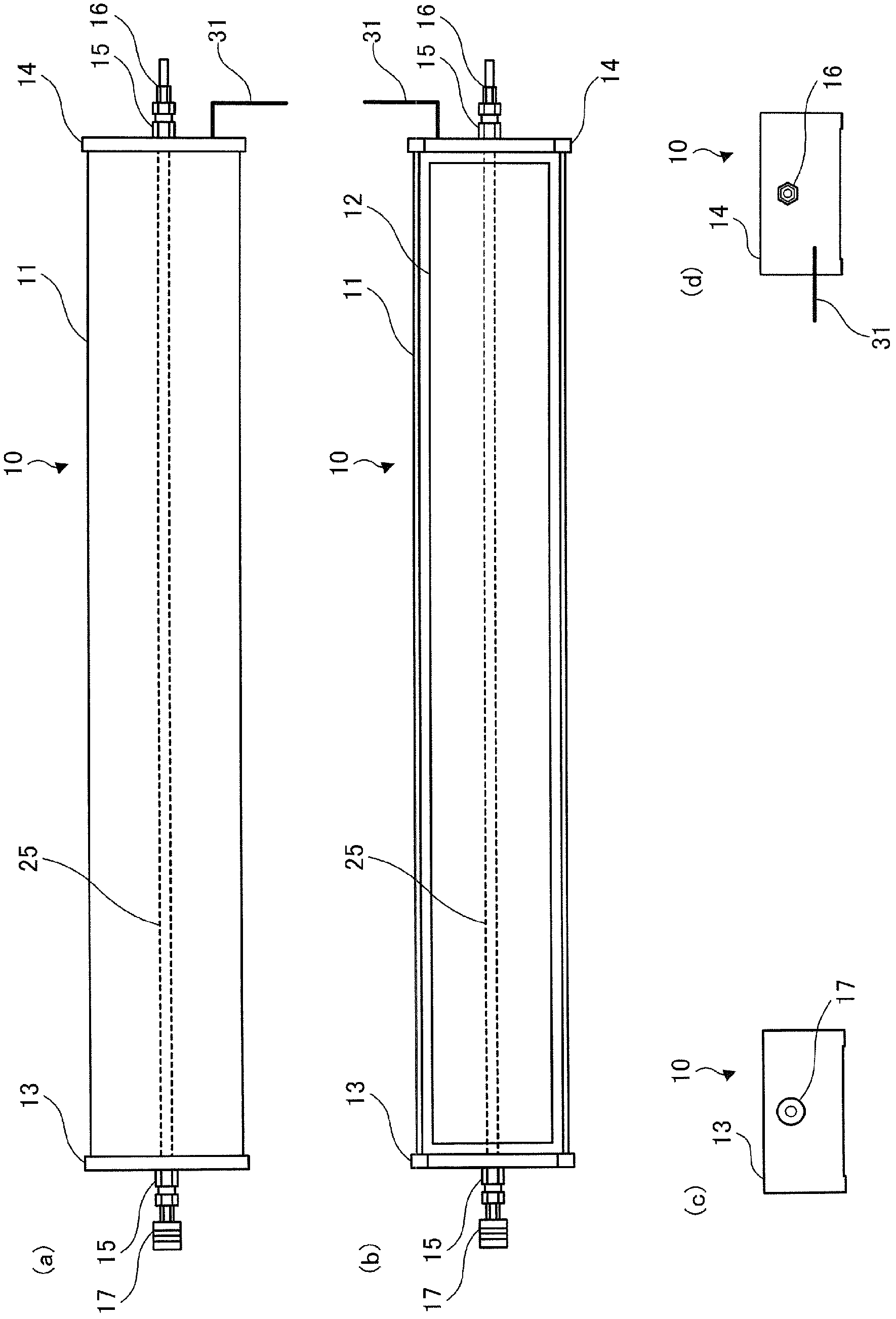

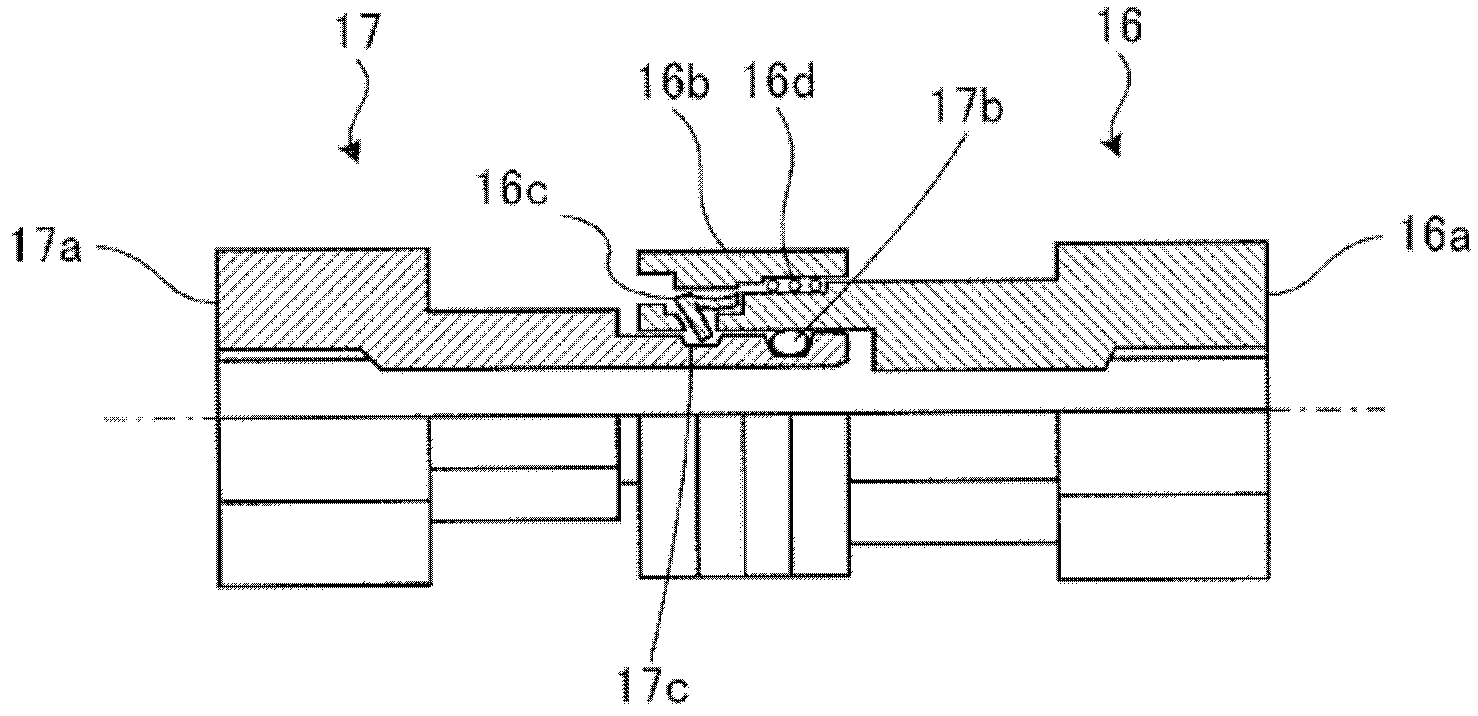

[0041] The plant cultivation system 1 is equipped with a plurality of cultivation containers 50 and a plurality of lighting devices 10. The plurality of cultivation containers 50 are arranged in the cultivation chamber 60 to cultivate plants. 50 are placed close together to irradiate the cultivated plants with light. The lighting device 10 is provided with a refrigerant pipe 25 , respectively. Also, a plurality of lighting devices 10 are connected by a connection unit. That is, the refrigerant conduit 25 of a lighting device 10 is connected to the refrigerant conduit 25 (adjacent refrigerant conduit) of an adjacent lighting device 10 to form a refrigerant flow path.

[0042]In addition, the plant cultivation system 1 includes an illumination control unit 30 installed outside the cultivation room 60 to control on / off of the illumination of the illumi...

no. 2 Embodiment approach

[0189] In the first embodiment, the light-emitting element assembly 21 including the first semiconductor light-emitting element 64a emitting blue light and the second semiconductor light-emitting element 64b emitting red light is mounted on the circuit board 22, and the circuit board 22 is mounted on a heat sink. Substrate 24. In this method, the heat generated from the first semiconductor light emitting element 64a and the second semiconductor light emitting element 64b is transferred from the back surface of the circuit substrate 22 to the heat dissipation substrate 24 through the metal leads of the light emitting element assembly 21 and the through holes of the circuit substrate 22. .

[0190] Among them, the thickness of the metal leads of the light-emitting element assembly 21 is as thin as 0.15 mm, but the thermal resistance of the light-emitting element assembly 21 is not so low as 100° C. / W.

[0191] In this embodiment, in order to further improve the cooling efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com