Labyrinth seal structure of powder concentrator

A technology of labyrinth seals and powder separators, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as rough product fineness, product quality impact, and current fluctuations in powder separator motors, and achieve product fineness And the effect of reasonable particle size distribution, reducing the difficulty of production control and enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

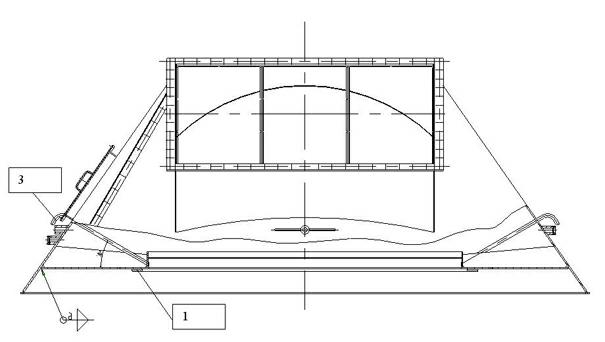

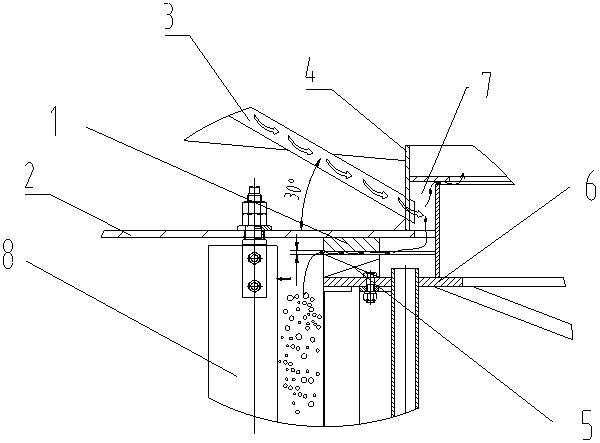

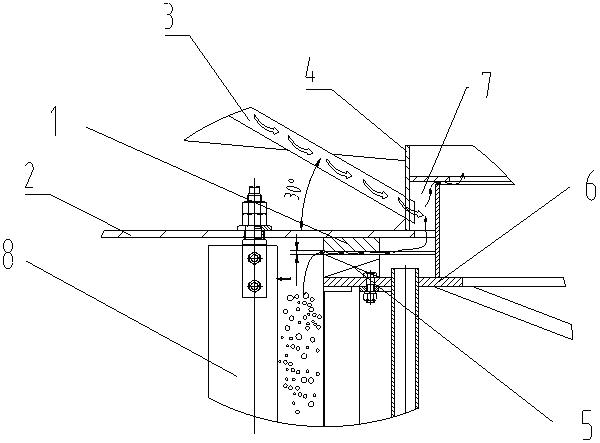

[0010] see figure 1 , 2 As shown, the upper sealing ring 1 is welded on the upper casing 2 of the powder concentrator, and the upper casing has a hole, and the elbow 3 is inserted into the rotor 6 and the stator from the hole at an angle of 30 degrees from the outside (sealed pipe, welded on the upper casing In the sealing gap 7 between the upper body 2) 4, the part of the elbow outside the upper shell is bent downwards in order to prevent the introduction of rainwater and other foreign substances. The lower sealing ring 5 is welded on the rotor 6 of the powder classifier. The guide vane is fixed on the upper casing 2. When the powder separator is working, the rotor drives the lower sealing ring to rotate, and the upper sealing ring and the elbow are fixed parts. The combination of upper and lower seals reduces the bypass from the powder selection area to the outlet pipe. The interior of the powder separator rotor is operated under negative pressure, but the elbow communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com