Discharge mechanism of steel bar truss forming machine

A steel truss and forming machine technology, applied in metal processing and other directions, can solve the problems affecting the normal operation and detachment of the steel truss forming machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

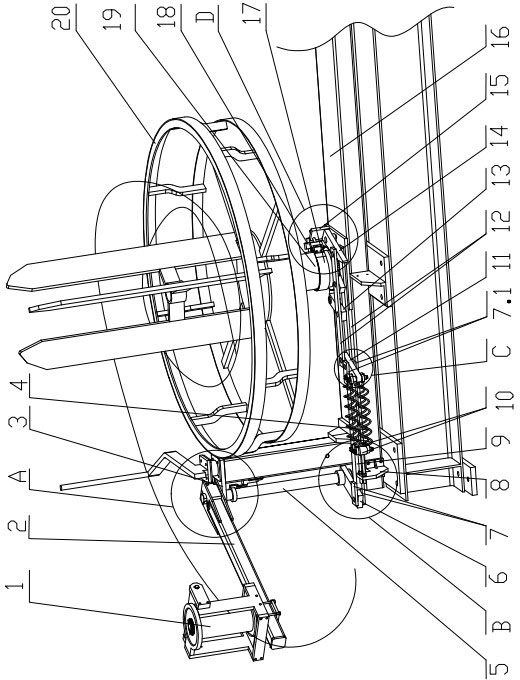

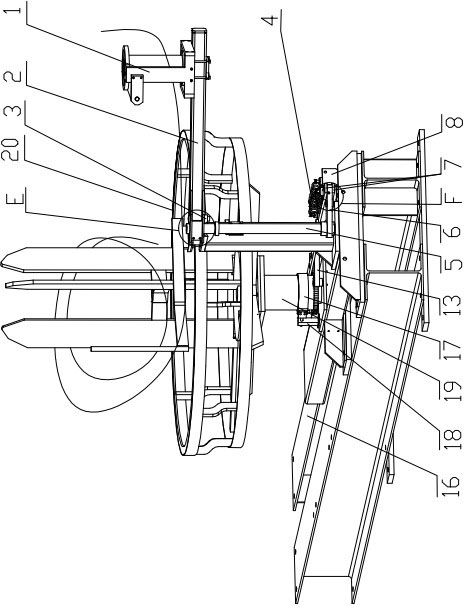

[0021] Depend on figure 1 As can be seen from the structural schematic diagram of the discharging mechanism of the steel bar truss forming machine of the present invention, it can be seen that it includes a coil rack 20, a steel bar output guide seat 1, a rotating column 19 arranged at the lower end of the coil rack 20, and the rotating column 19 is rotationally connected with the frame 16. Including the interlocking device that the steel bar output guide seat 1 outputs the steel bar to rotate or stop and the coil rack 20 rotates or stops; When exporting steel bars, the coil rack does not rotate.

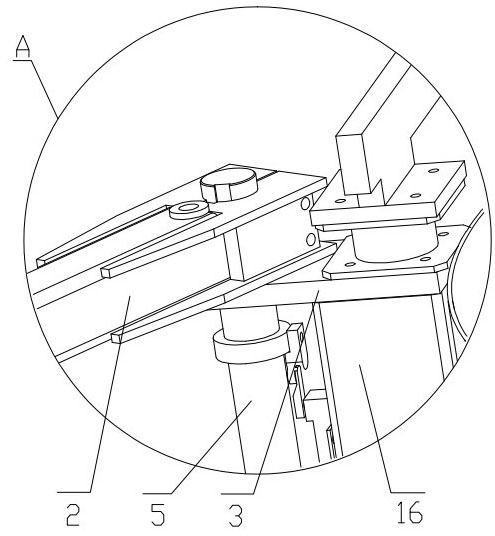

[0022] The linkage device includes a guide seat 1 for drawing steel bars, the guide seat 1 is fixed on one end of the rocker arm 2, the other end of the rocker arm 2 is hinged with the connecting rod seat 3 fixed on the frame 16, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com