Unlocking branching mechanism of automobile back seat

A technology for backrest and seat, applied in the field of locking devices, can solve the problems of operator frustration, large unlocking stroke, unbalanced unlocking force, etc., and achieve the effect of easy operation, balanced unlocking force and compact shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

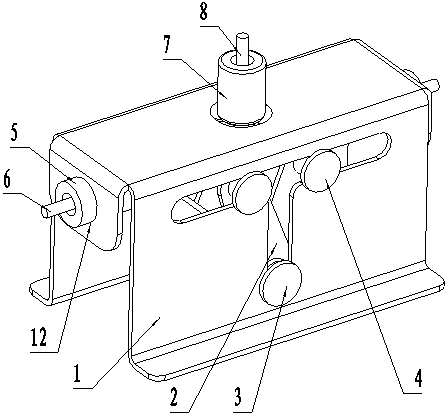

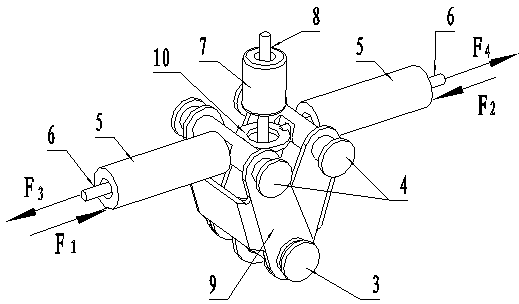

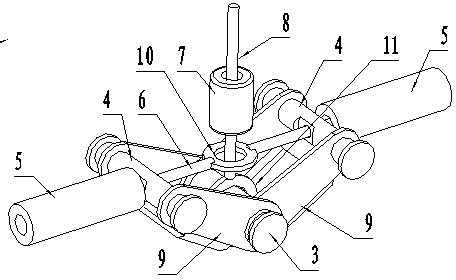

[0016] see Figure 1-3 , the present invention includes a junction box 1, an intermediate shaft 3, an intermediate stay wire 8, and symmetrically arranged two side shafts 4, two connecting rods 9, two side stay wires 6 and two stay wire sleeves 5. T-shaped slots 2 are arranged on the front and rear walls of the junction box corresponding to each other, and sleeve holes 12 are arranged on the left and right walls of the junction box correspondingly. The two ends of the intermediate shaft 3 are located in the vertical groove of the T-shaped groove, and the intermediate shaft and the vertical groove form a sliding fit; The transverse groove forms a sliding fit. The two ends of the connecting rod 9 are respectively hinged to the middle shaft and the side shaft, and the bottom of the middle stay wire 8 is connected to the bottom ring 11, and the bottom ring is sleeved on the middle shaft. Two backguy sleeves 5 are respectively located in the left and right sleeve holes 12 and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com