Track-wheel combined type mobile robot

A mobile robot and composite technology, applied in the field of mobile robots, can solve the problems of overall reliability, reduced flexibility, and complex control of the robot, and achieve the effects of simplifying the structure, ensuring flexibility, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

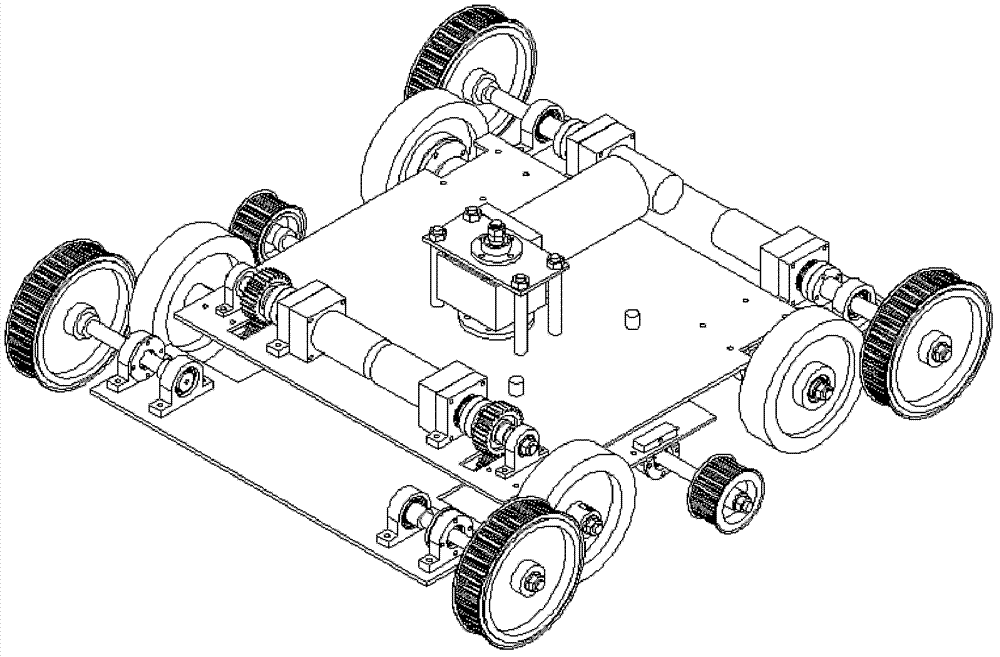

[0029] combine figure 1 , the main constitution of the present invention comprises three main parts of the conversion mechanism of crawler chassis, wheel chassis and crawler-wheel.

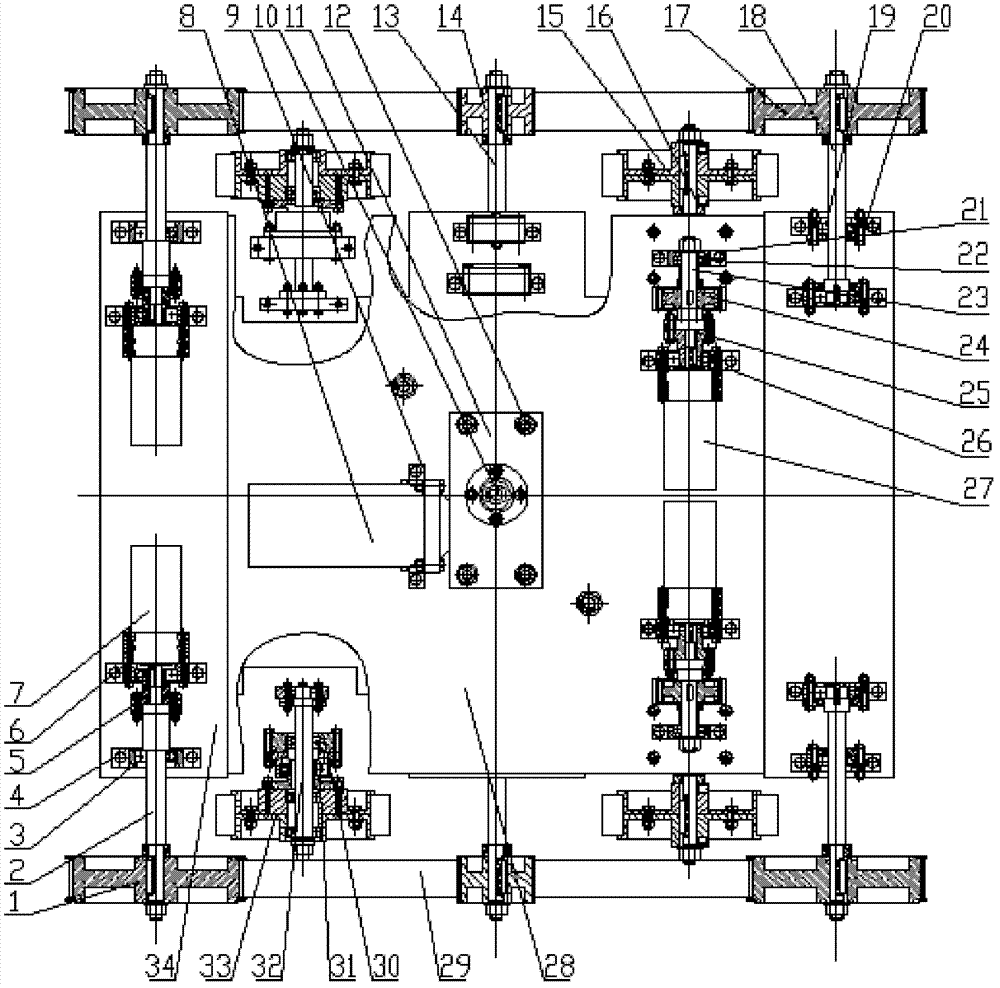

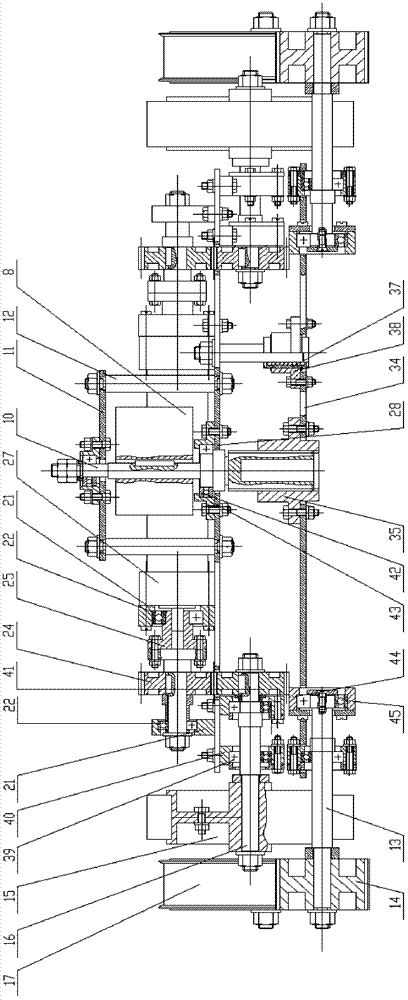

[0030] combine figure 2 , image 3 , Figure 4 , the crawler driving mechanism is installed on the bottom plate 34 of the crawler driving mechanism, the crawler driving motor 7 is a DC gear motor and is connected with the crawler driving motor support 6 through screws, and it transmits power through the active crawler coupling 5 to the active track wheel shaft 2, and then the active track wheel shaft 2 drives the active track wheel 1 to move through a key connection, and the active track wheel shaft 2 is jointly connected by the active track wheel bearing 3 and the active track wheel bearing seat 4 installed on the bottom plate 34 of the track wheel traveling mechanism. Match support. The driven track wheel 17 is installed on the driven track wheel shaft 18 through a key connection, and moves...

specific Embodiment approach 2

[0034] combine Figure 9 , the wheel running mechanism is installed on the wheel running mechanism bottom plate 28, the wheel driving motor 27 is a DC geared motor and is connected with the wheel driving motor support 26 by screws, and it transmits power to the driving wheel drive through the driving wheel coupling 25. Shaft 23, driving wheel transmission shaft 23 is transmitted by a pair of driving gear 24 and driven gear 41 of specified reduction ratio, and power is transmitted to driving wheel shaft 16, and finally drives driving wheel 15 to move, and driving wheel transmission shaft 23 is driven by driving wheel shaft 23. The wheel transmission bearing 22 is jointly supported by the driving wheel transmission bearing seat 21 , and the driving wheel shaft 16 is jointly supported by the driving wheel bearing 39 and the driving wheel bearing seat 40 .

[0035] The working principle of the present invention is as follows:

[0036] When the mobile robot travels on a relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com