Method and device for automatically bagging lump materials

A block material and bagging device technology, applied in packaging and other directions, can solve the problems of low manual bagging ability, complex equipment structure, and large impact of rubber blocks, etc., to reduce labor intensity, simple equipment structure, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

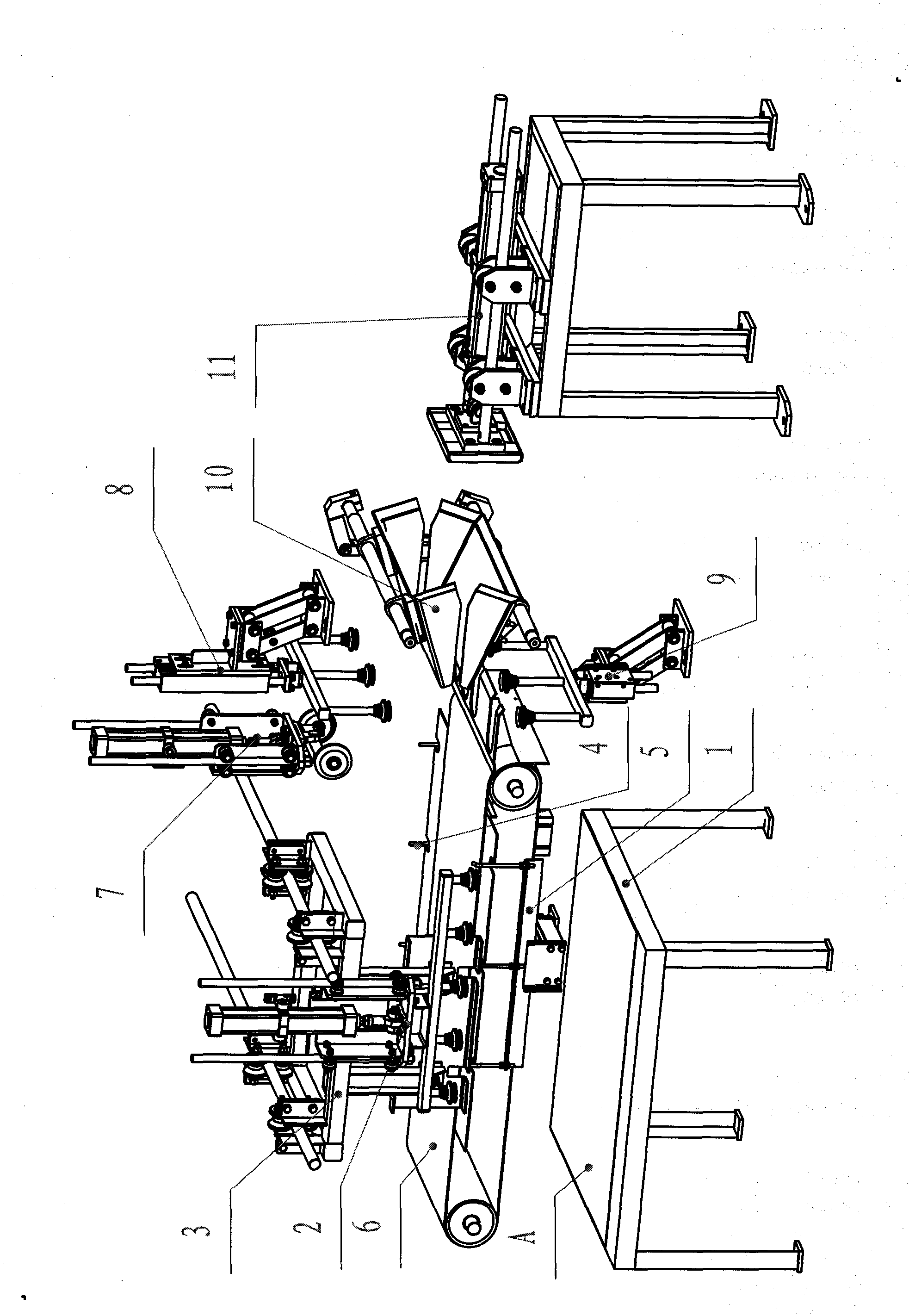

[0036] The specific embodiment of the present invention sees Figure 1 to Figure 10 , the automatic bagging method for bulk materials includes the following process steps:

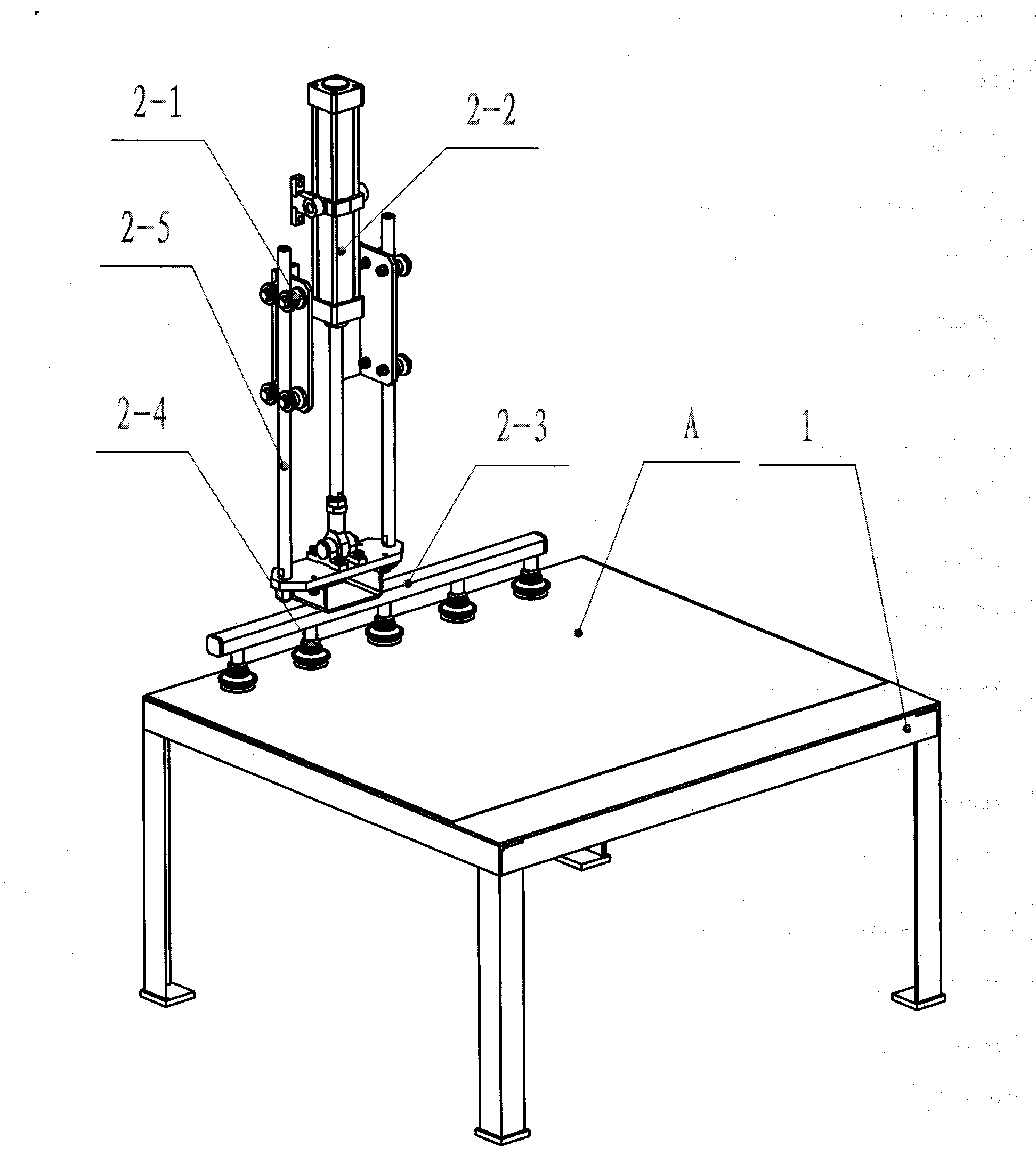

[0037] (1) Suction empty bag: the suction cup holder (2-3) moves downwards, sucks the empty bag (A) located on the bag storage device (1) with the bag taking suction cup (2-4), and then the suction cup holder (2-4) 3) Move up to the initial position;

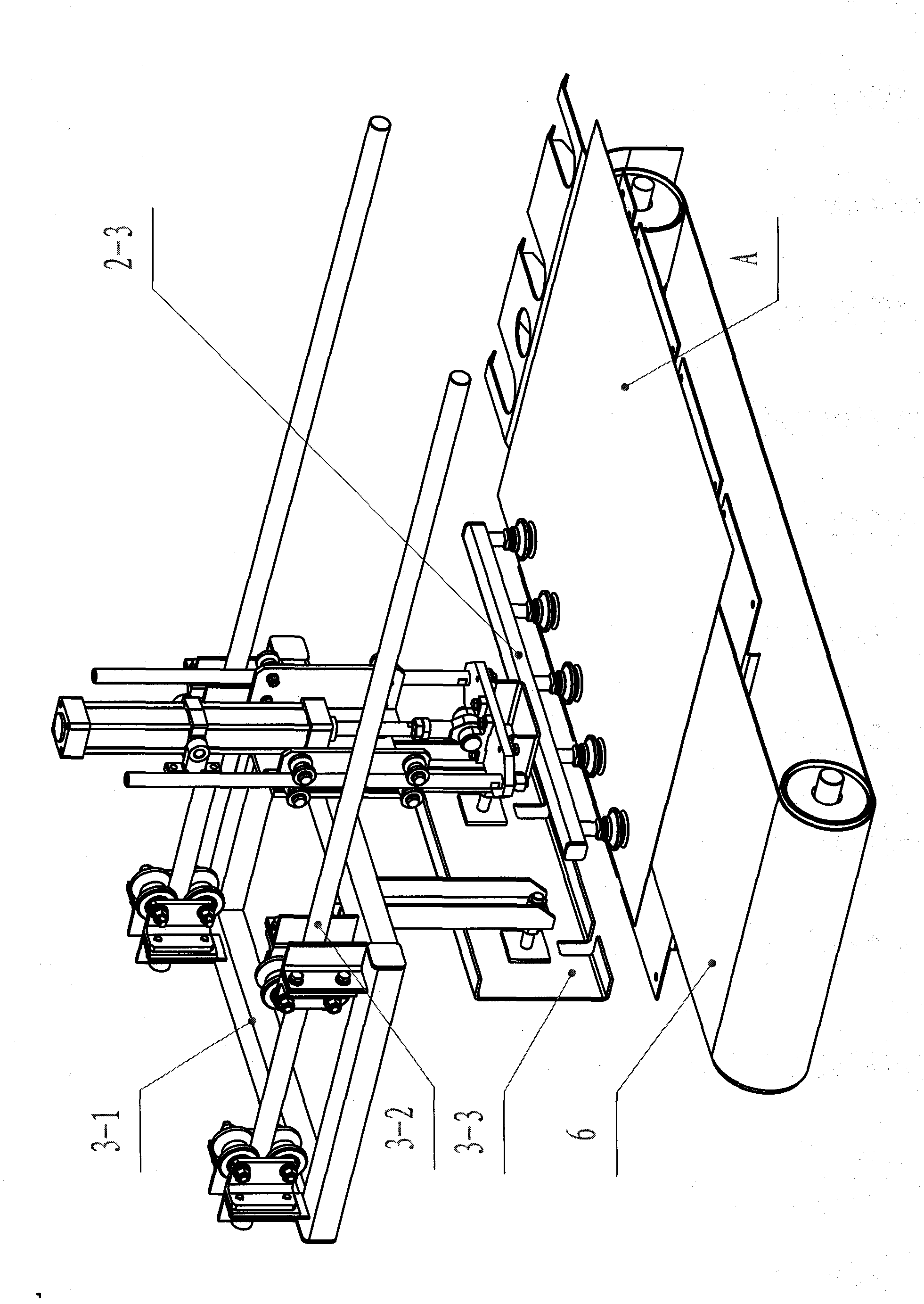

[0038] (2) Empty bags: push the trolley (3-1) to drive the suction cup frame (2-3) to move to the left, put the sucked empty bags (A) on the conveyor belt (6), and then push the trolley (3- 1) Drive the suction cup holder (2-3) to move to the right to absorb the empty bag position, and start to absorb the next empty packaging bag;

[0039] (3) Arranging empty bags: the left gear lever (4-2) on the left side of the conveyor belt (6) rises, and the right gear lever (5-2) on the right side of the conveyor belt (6) moves to the left, and the empty bags The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com