Seabed ore gathering vehicle

A mining vehicle and mine collection technology, which is applied in the field of vehicles, can solve the problems of reducing loading capacity, compressing storage space, compressing compartment space, etc., to reduce the difficulty of manufacturing and control, reduce the requirements of turning radius, and improve collection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

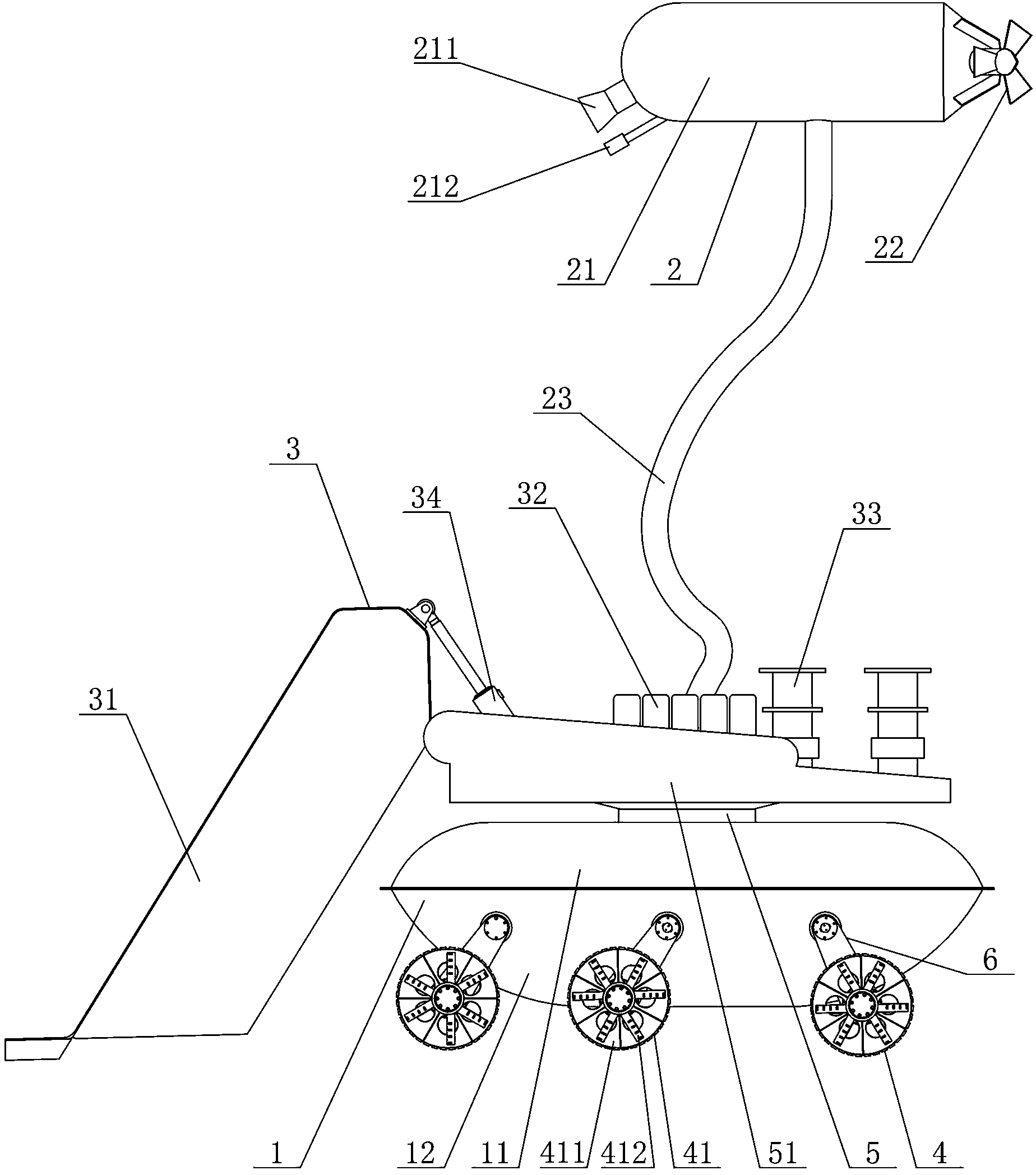

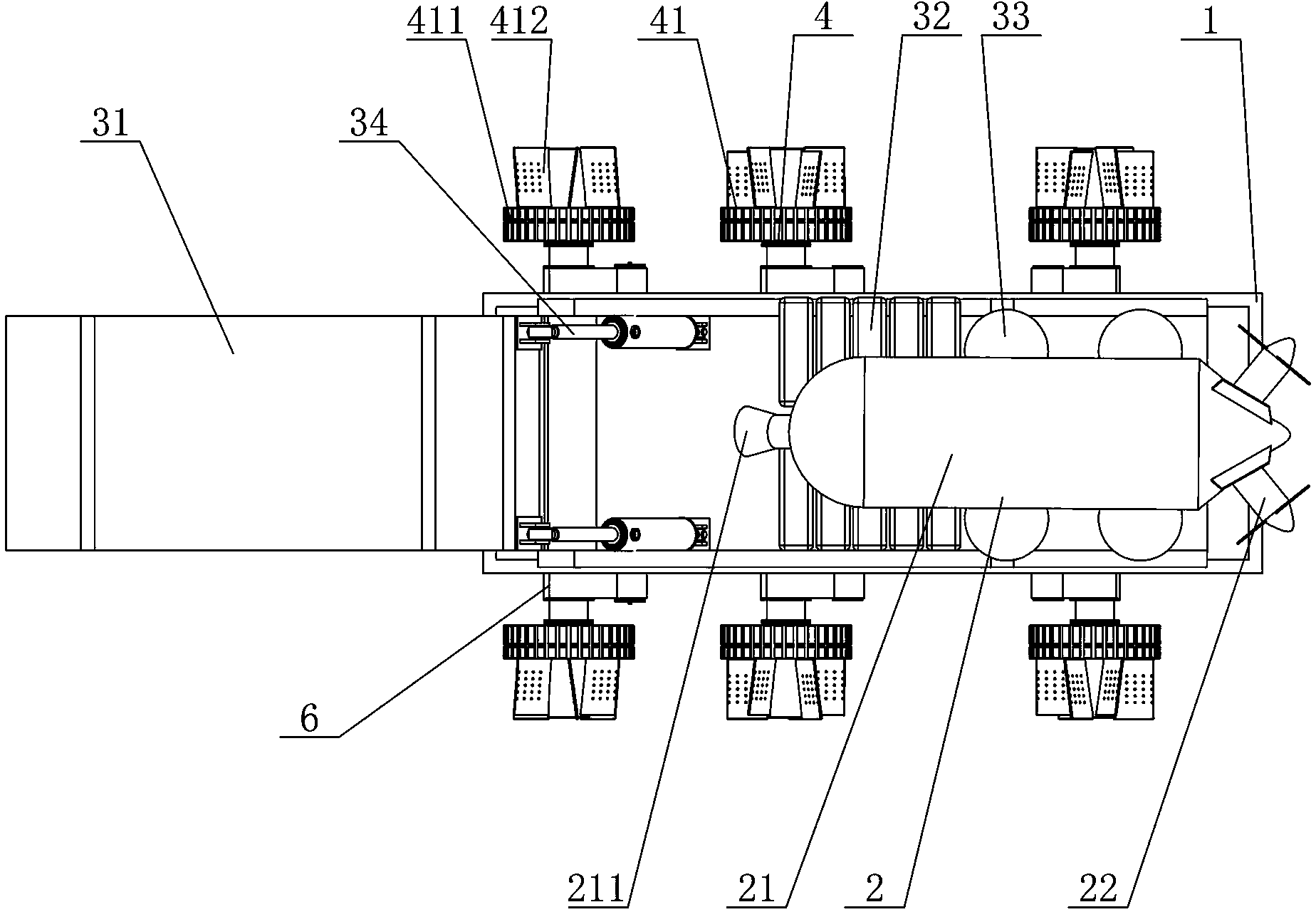

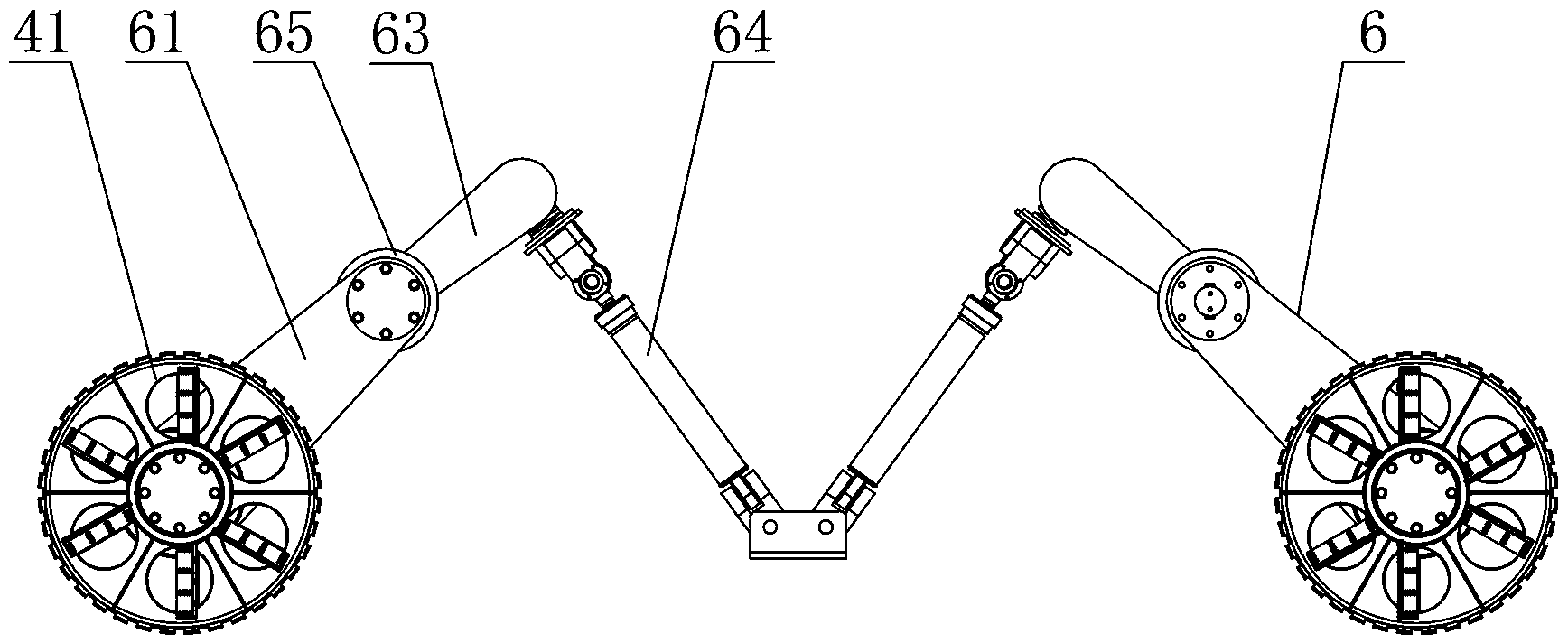

[0032] figure 1 and figure 2 A kind of embodiment of the seabed mine collection vehicle of the present invention is shown, the seabed mine collection vehicle comprises a body assembly 1, a power assembly 2, and a mine collection mechanism 3 and a walking mechanism 4 installed on the body assembly 1, and the mine collection mechanism 3 passes through A rotating assembly 5 is installed on the body assembly 1, so that the ore collecting mechanism 3 can rotate relative to the body assembly 1, and it is not necessary to drive the body assembly 1 in the process of collecting metal minerals on the same route in the seabed mining area by the ore collecting vehicle Turn around, and only need to rotate the ore collecting mechanism 180 degrees through the rotating component 5, and then reversely drive the traveling mechanism to collect polymet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com