Timely yield supporting system for deep high-stress broken-expansion surrounding rocks

A high-stress, surrounding rock technology, applied in special data processing applications, wellbore lining, tunnel lining, etc., can solve problems such as rare research work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

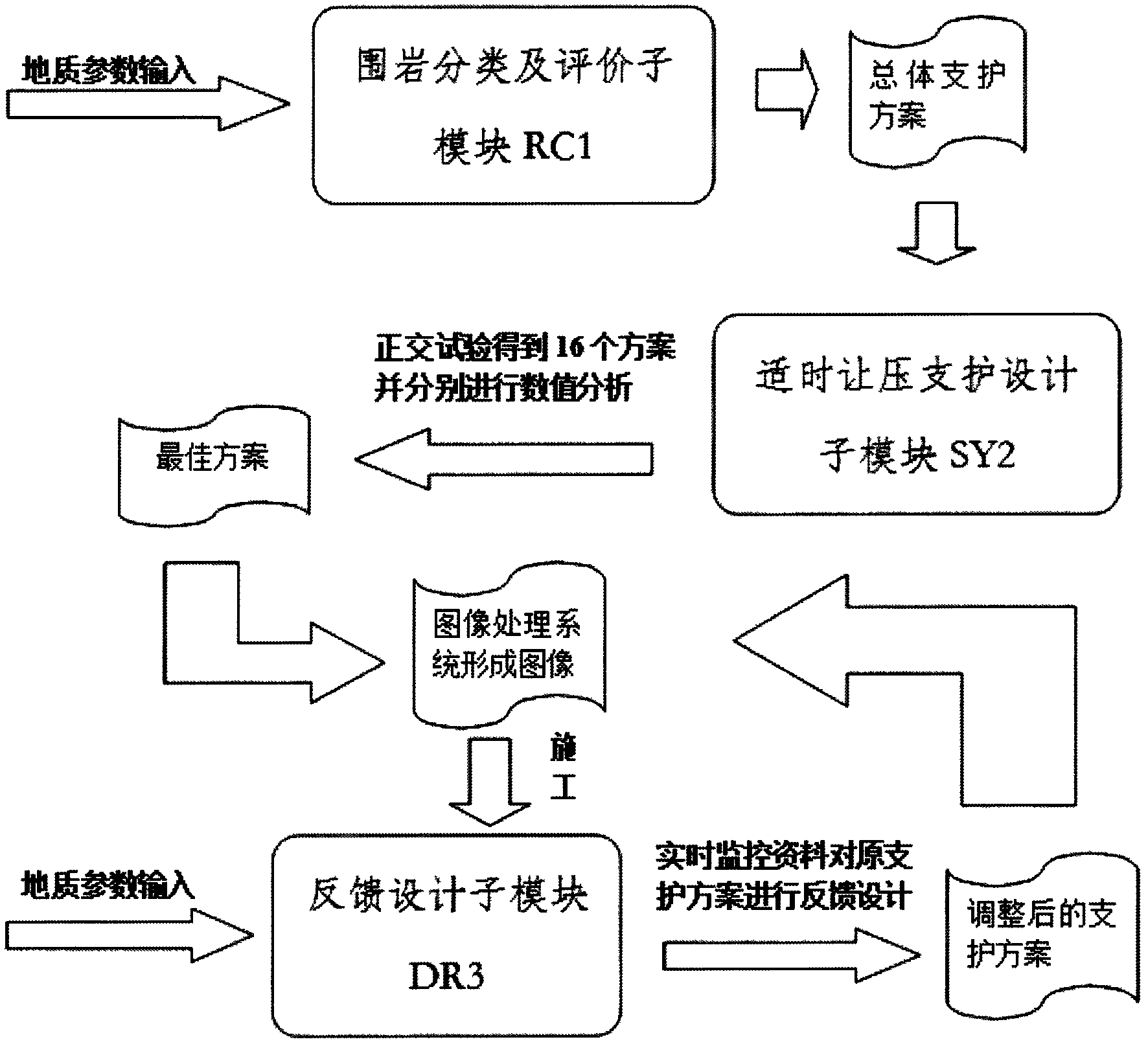

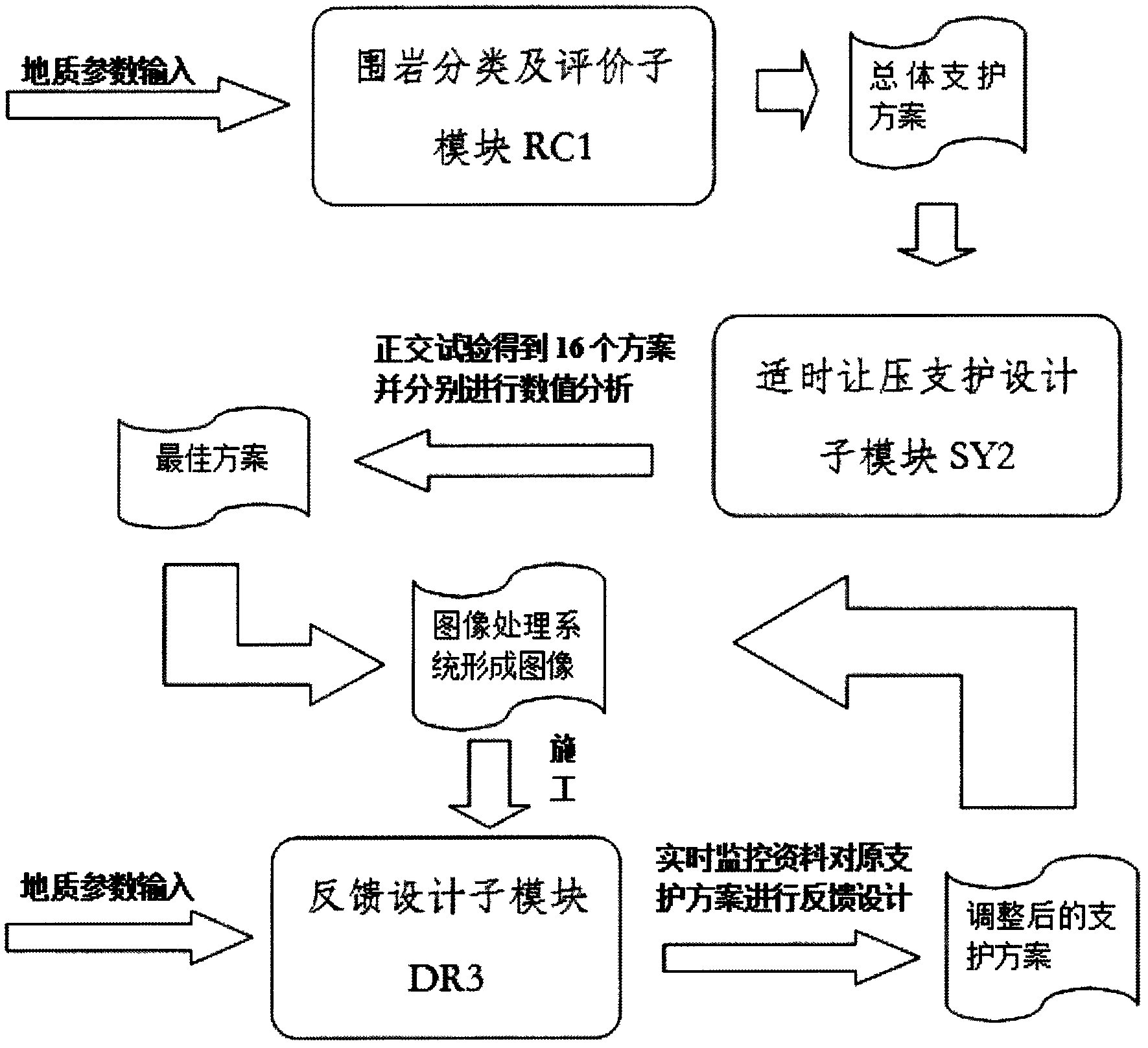

[0013] The present invention will be further elaborated below in conjunction with specific examples. As shown in the flow chart: a timely yielding support system for deep high-stress bulging surrounding rocks in this embodiment mainly includes surrounding rock classification and evaluation sub-module RC1, timely yielding support design sub-module SY2 and Feedback design sub-module DR3; where:

[0014] The surrounding rock classification and evaluation sub-module RC1 is used to calculate and analyze the parameter input according to the engineering geological survey to obtain the overall support scheme;

[0015] The timely yield support design sub-module SY2 is used to receive the calculation results obtained in the surrounding rock classification and evaluation sub-module RC1 and the overall support plan, and the system OET4 is used to obtain 16 three-factor four-level orthogonal test design methods. According to the best plan obtained by the comprehensive evaluation and optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com