Prediction method for surface thin film residual stress

A technology of residual stress and prediction method, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of influence, poor repeatability, limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

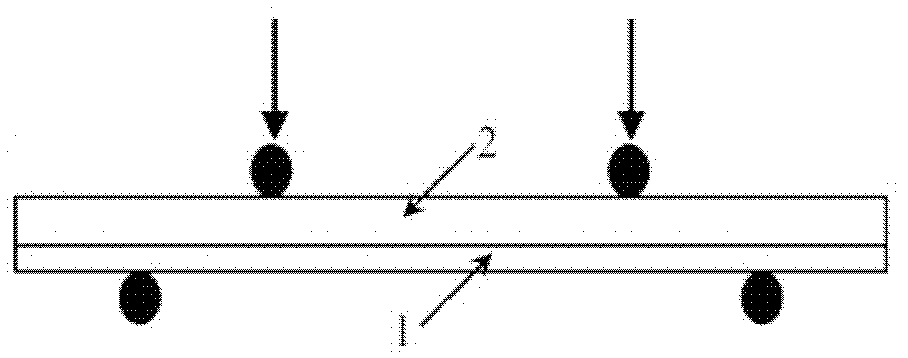

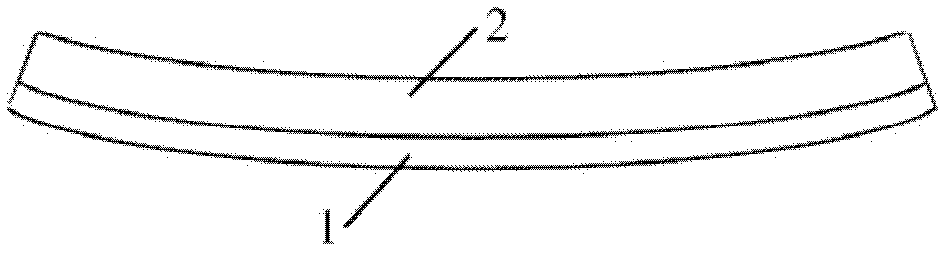

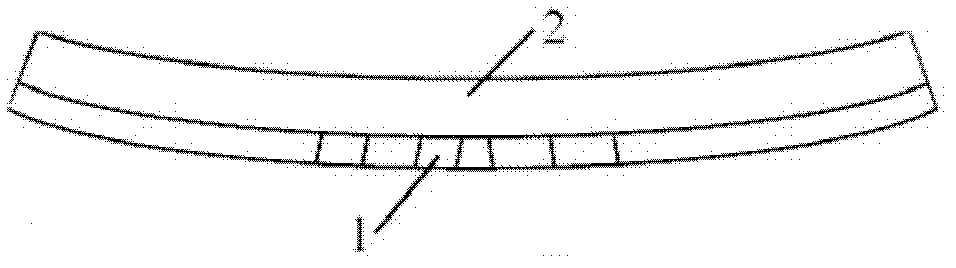

Embodiment 1

[0109] The surface of nickel-based 617 alloy with a thickness of 1 mm was ground with 200-grit sandpaper, and then the surface was cleaned with chemical ultrasonic waves, and then a YSZ film with a thickness of 3.1 μm was deposited by magnetron sputtering. Determination of residual stress value σ of thin films by curvature method r was -149MPa, and the Young's modulus E of the film and the substrate was determined by the nanoindentation method. f and E s 70GPa and 214GPa, respectively, Poisson's ratio v for film and matrix f and v s Set to 0.23 and 0.288, respectively. The four-point bending experiment of the film was carried out under the in-situ observation environment of scanning electron microscope, and the critical strain value ε of the film crack initiation observed experimentally c about 0.28%. After multiple cracks are generated inside the film, at different bending strain values ε a Next, stop the load, record the number N of internal cracks in the film in the...

Embodiment 2

[0113] The surface of nickel-based 617 alloy with a thickness of 1 mm was ground with 400-grit sandpaper, and then the surface was cleaned with chemical ultrasonic waves, and then a YSZ film with a thickness of 7.1 μm was deposited by magnetron sputtering. Determination of residual stress σ of thin films by X-ray diffraction r was -129MPa, and the Young's modulus E of the film and the substrate was determined by the nanoindentation method f and E s 68GPa and 214GPa, respectively, Poisson’s ratios v for film and matrix f and v s Set to 0.23 and 0.288, respectively. The four-point bending experiment of the film was carried out under the in-situ observation environment of the optical microscope, and the critical strain value ε of the film crack initiation observed experimentally c about 0.22%. At different bending strains, the load is stopped, the number N of internal cracks in the film in the observation interval is recorded in a timely manner, and the width L of the observ...

Embodiment 3

[0117] The surface of nickel-based 617 alloy with a thickness of 1 mm was ground with 220-grit sandpaper, and then the surface was cleaned with chemical ultrasonic waves, and then a YSZ film with a thickness of 9.0 μm was deposited by magnetron sputtering. Determination of residual stress value σ of thin films by curvature method r was -73MPa, and the Young's modulus E of the film and the substrate was determined by the nanoindentation method. f and E s 68GPa and 214GPa, respectively, Poisson’s ratios v for film and matrix f and v s Set to 0.23 and 0.288, respectively. The four-point bending experiment of the film was carried out under the in-situ observation environment of scanning electron microscope, and the critical strain value ε of the film crack initiation observed experimentally c about 0.13%. At different bending strains, the load is stopped, the number N of internal cracks in the film in the observation interval is recorded in a timely manner, and the width L of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com