Infrared-ray oven

An infrared oven and infrared technology are applied in clothing, shoe parts, shoemaking machinery, etc., which can solve the problems of high equipment operating costs, large energy consumption losses, and inability to observe changes in shoes, etc., to reduce equipment operating costs, The effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

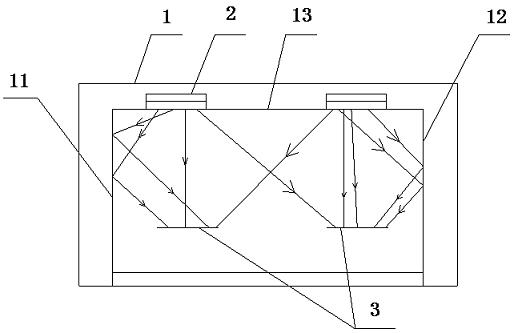

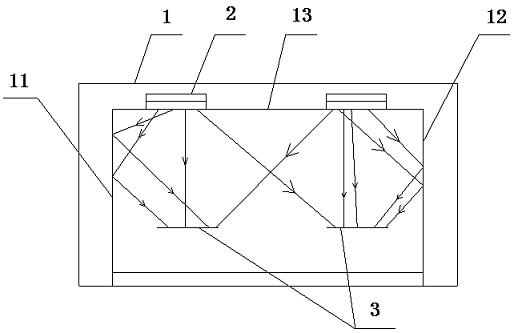

[0010] Such as figure 1 As shown, an infrared oven includes a box body 1, and an infrared heating device 2 is arranged on one of the side plates of the box body 1. In this embodiment, the infrared heating device 2 is an infrared lamp tube. The surface of at least one side plate of the box body 1 is provided with a reflective layer for reflecting infrared light. The reflective layer is a titanium plate, and the surface of the titanium plate can effectively reflect the infrared light emitted by the infrared lamp tube to the bottom of the shoe 3. sole or upper. In this embodiment, the upper side plate 13 of the box body 1 is provided with an infrared heating device 2, and the left side plate 11, the right side plate 12 and the upper side plate 13 of the box body are provided with a reflective layer for reflecting infrared rays. The front side panel of body 1 is a transparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com