Multifunctional section-variable formwork

A multi-functional, formwork technology, applied in the field of formwork/formwork components, construction components on-site preparation, construction, etc., can solve the problems of low cost performance of formwork and lack of universal applicability, and achieve easy and simple disassembly and various assembly methods , Effects of various shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

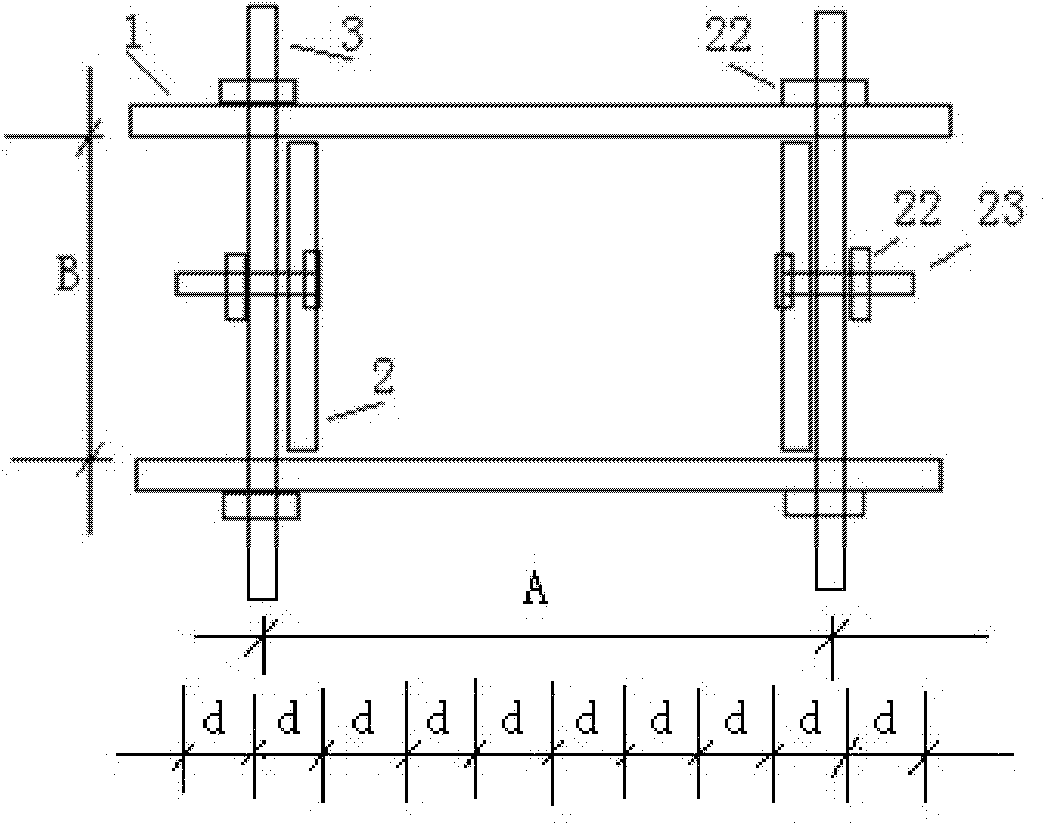

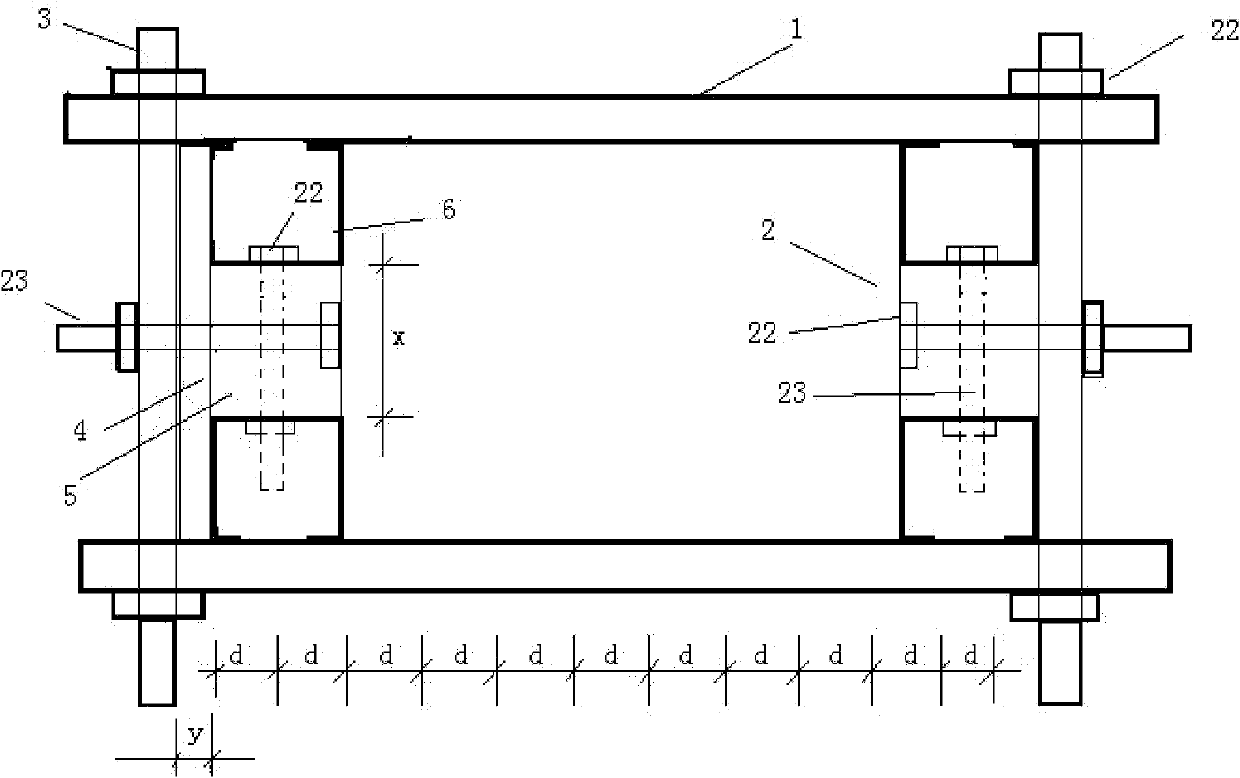

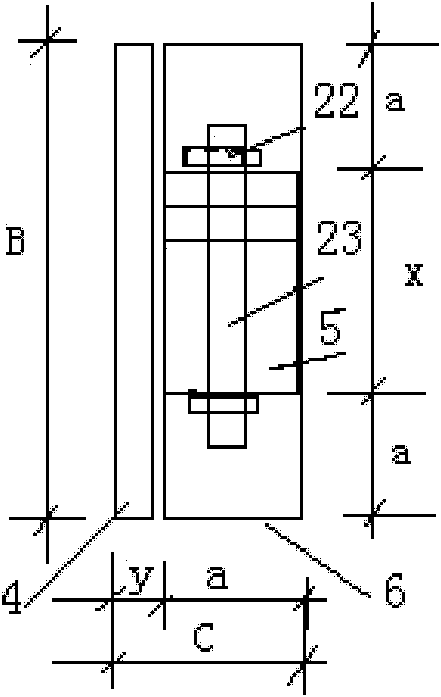

[0070] For the specific hole opening method, please refer to the attached Figures 21 to 24 , with Figure 21 Among them is the side plate made of a single material, such as the side plate made of aluminum steel. Because the side plate made of a single material is usually made of iron steel, aluminum steel, alloy steel or plastic steel, it has high strength and can be connected by screws. It can ensure the strength requirements of formwork installation. Such as Figure 21 As shown in , holes can be regularly opened on the side plate 1 before use, and the distribution of the holes 24 can be evenly distributed on the side plate 1 as shown in the figure, or can be distributed according to certain specifications, such as common sizes in construction . After the holes 24 are set in advance, the splint 2 can be directly and conveniently adjusted to the position of the side plate 1 during installation. The size adjustment when assembling the template, such as fixing the splint 2 ...

Embodiment 2

[0078] Adjustment of any size in the length direction of the formwork section can be realized by specifically setting the length fine-tuning plate 4, and the main value of the length of the formwork section is determined by fixing the position of the splint 2 on the connecting hole 24 on the side plate 1, and then by adding the length fine-tuning The length of the plate 4 is used to further adjust the length of the template section, which can ensure the accuracy of the size.

[0079] Example 3

Embodiment 3

[0081] Such as Figure 4 As shown, in the height direction or the length direction of the cross-section side plate, a "one"-shaped plate groove structure 13 can be set on one side plate, and the two side plates can be connected together through the "one"-shaped plate groove structure 13. , so that it can meet the adjustment of non-standard size on the height of the side plate, and the length of the side plate on the cross section can meet the requirements of any size, and can meet the needs of concrete pouring of different sizes. Such as Figure 4 As shown, the first side plate 11 realizes the connection between the first side plate 11 and the second side plate 12 by inserting the "one"-shaped plate groove structure 13 on the second side plate 12. On the inner surface of the side plate, due to The difference between the first side plate 11 and the second side plate 12 is the thickness of a side plate, which can be realized by adding a filling plate 14 to the inner surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com