Deformation anchor cable capable of increasing resistance continuously

A technology of anchor cable and threaded connection, which is applied in the field of anchor cables, can solve problems such as damage accidents, unstable performance, failure of anchor cables, etc., and achieve the effects of increased work resistance, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

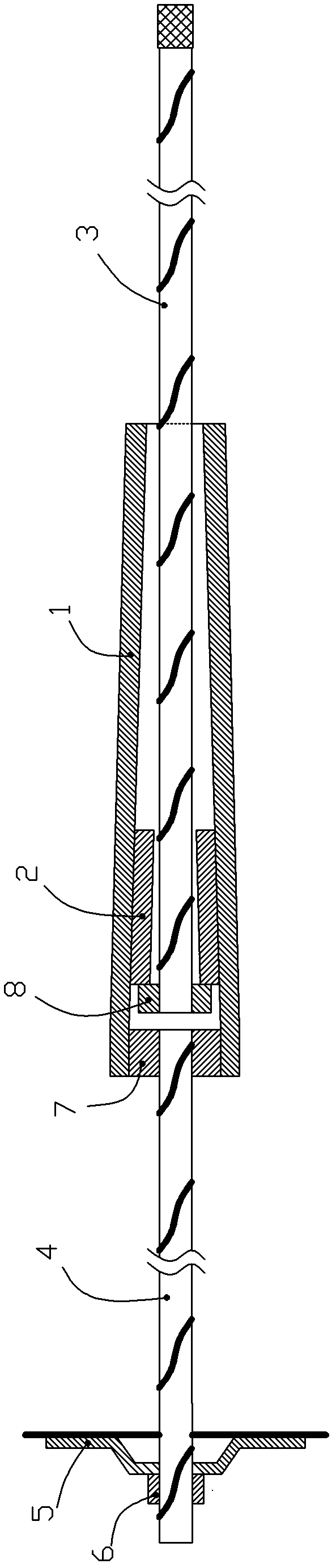

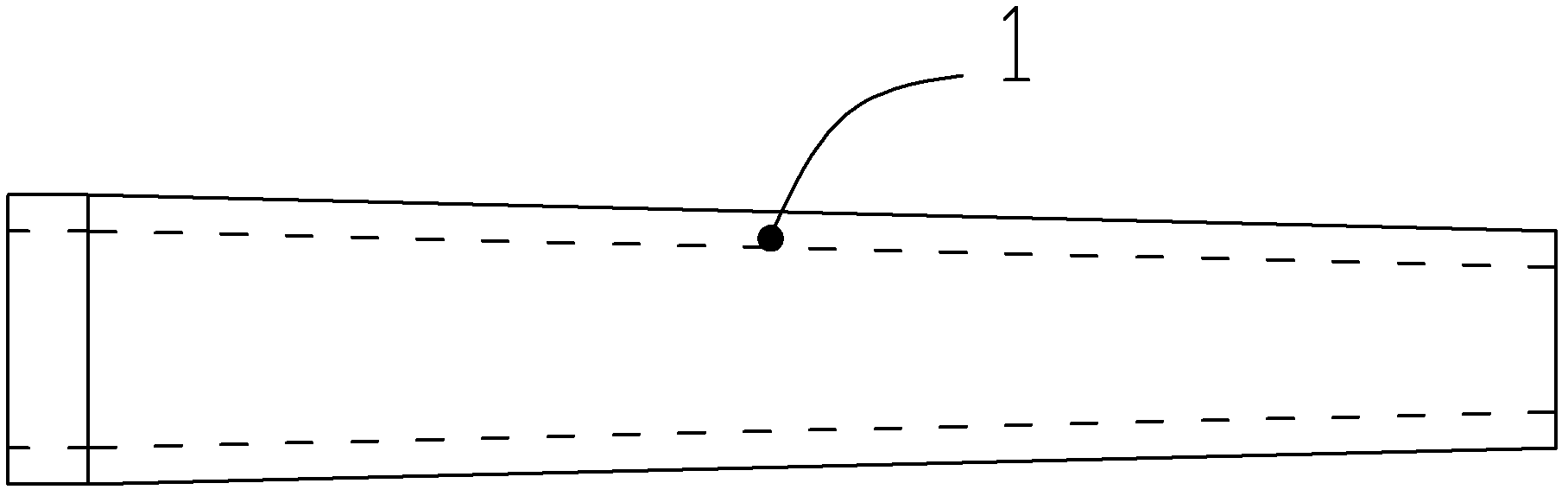

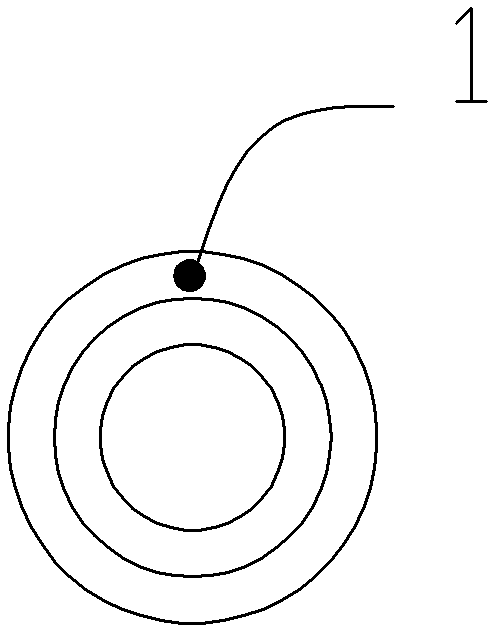

[0027] combine Figure 1 to Figure 5 , a continuous resistance increasing deformation anchor cable, including a friction sleeve 1, a retractable member 2, a first fixed cable 3, a second fixed cable 4, a tray 5 and a nut 6.

[0028] The inner diameter of the above-mentioned friction sleeve gradually decreases from one end of the sleeve to the other end. Such as the selection of frustum-shaped or conical steel pipes. In addition to the conventional smooth surface structure, the inner and outer pipe walls of the above-mentioned friction sleeve can also adopt such a preferred method, that is, the inner pipe wall, or the inner pipe wall and the outer pipe wall are provided with circumferential ribs, Used to increase the coefficient of friction. A second fixed cable is arranged at the nozzle end with a large inner diameter of the above-mentioned friction sleeve, and the second fixed cable is connected to the nozzle end through the cable end 7; the above-mentioned cable end 7 and ...

Embodiment 2

[0032] combine Image 6 , a continuous resistance-increasing deformable anchor cable, comprising a friction sleeve 1 , a retractable member 2 , a first fixed cable 3 , a tray 5 and a nut 6 .

[0033] The inner diameter of the above-mentioned friction sleeve gradually decreases from one end of the sleeve to the other end. Such as the selection of frustum-shaped or conical steel pipes. In addition to the conventional smooth surface structure, the inner tube wall of the above-mentioned friction sleeve can also adopt such a preferred method, that is, the inner tube wall is provided with circumferential ribs to increase the coefficient of friction. A connecting rod 4 is arranged at the nozzle end with a large inner diameter of the above-mentioned friction sleeve, and the connecting rod is connected with the nozzle end through the sleeve end plug 7; the above-mentioned casing end plug and the nozzle end can be connected by threads.

[0034] The above-mentioned shrinkable member, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com