Top caving type gangue filling hydraulic support and filling method

A technology of hydraulic support and gangue, which is applied in the field of roof-caving gangue filling hydraulic support and filling, can solve the problems of slow coal mining speed, filling failure, and occupation of filling space, so as to increase the applicable mining height range, increase filling width, and improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

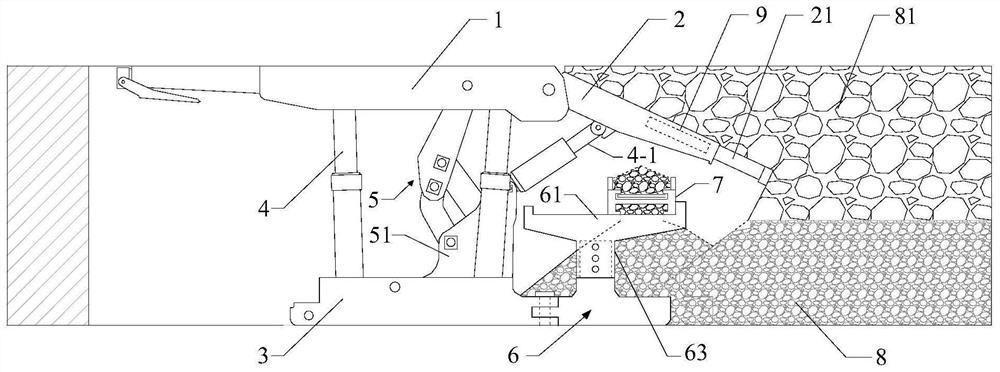

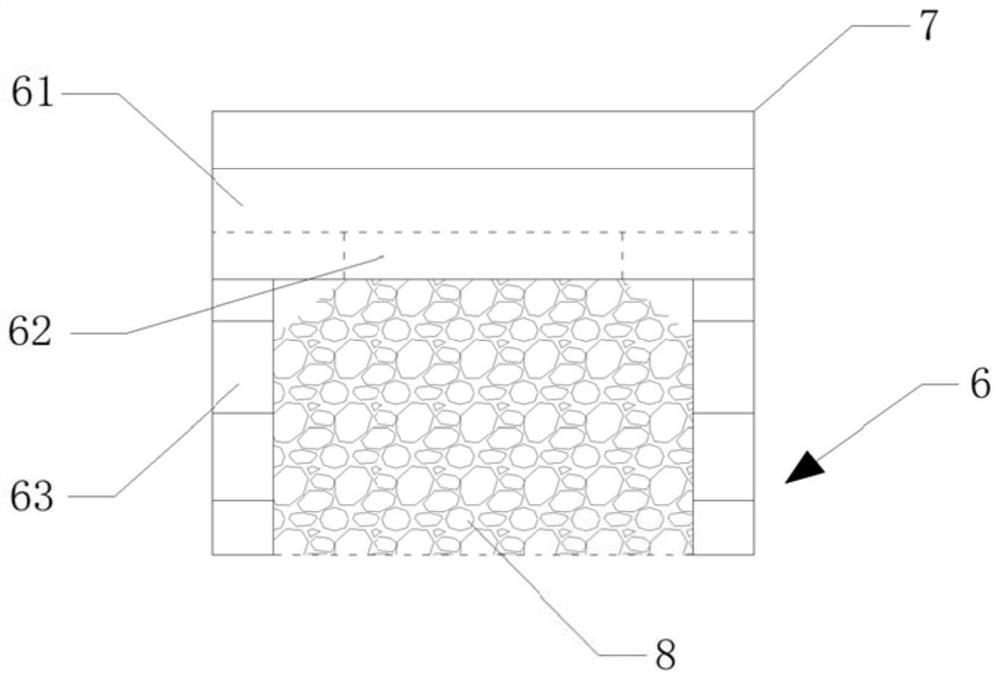

[0050] When applied to a full-height mining face, the roof caving type gangue filling hydraulic support provided by the present invention is arranged in a row on the coal mining face, and the bottom unloading gangue leaking scrapers 7 are connected with each other to form a bottom unloading gangue leaking scraper conveyor , before recovery, adjust the height of the straddle platform 6 through the plug-type telescopic structure according to the mining height of the working face, so that the height of the straddle platform 6 meets the filling height requirements, and does not interfere with the support cylinder 41 at the same time. The gangue filling hydraulic support moves forward, the roof collapsed rock block 81 is not strung into the filling space under the cover of the cover beam 2, and the gangue filling material is transported by the belt to the end of the bottom dumping gangue leaking scraper 7, and the bottom dumping gangue leaking scraper 7. After the conveyor is starte...

Embodiment 2

[0052] When applied to the top coal caving mining working face, the roof caving type gangue filling hydraulic support provided by the present invention is arranged in a row on the coal mining working face, and the bottom unloading gangue leaking scrapers 7 are connected with each other to form the bottom unloading gangue leaking scraper conveying machine, before recovery, adjust the height of the straddle platform 6 through the plug-type telescopic structure according to the mining height of the working face, so that the height of the straddle platform 6 meets the filling height requirements, and does not interfere with the support cylinder 41 at the same time. The gangue filling hydraulic support moves forward, and the roof collapsed coal blocks 81 are not strung into the filling space under the cover of the cover beam 2, and the gangue filling material is transported to the end of the bottom discharge scraper 7 through the belt, and the bottom discharge scraper scraper 7 Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com